I’ve completed my mods (for the time being) on my CrossFire. Some of these might be useful to others so I’ll just highlight them here and feel free to ask questions (PM if you want gory details).

There were a number of things that were immediately apparent when I thought about putting the CrossFire in my workshop. The most obvious one was how to keep the sparks from setting my woodshop on fire! ![]()

While not necessarily a CrossFire mod, it ended up creating the need for some. I concluded/hoped that I could use some fiberglass welding blankets as a curtain to contain the sparks and, when I decided on the location, I decided that:

- The curtains should be retractable so I don’t lose access to my clamps or wood storage shelves.

- The Y motor and electronics enclosure needed to be moved from the normal location.

The Y motor was easy, it easily moved to the opposite end of the Y rail and I simply flipped the polarity of the Direction pin in Mach3 configuration. The X & Y motor cables, however, needed to be extended to reach the new location of the enclosure.

This worked ok for my initial setup, but created three problems.

First, the X cable dangled behind the entire length of the Y rail when the Y axis was moved. This in itself isn’t a problem UNLESS you plan to use stock larger than 2x2. The dangling cable blocked the space between the Y rail and table so you couldn’t expand the workpiece in the X direction. This I solved by adding a drag chain to keep the X Motor cables neatly away from the table and moving mechanisms.

The second problem was that my stiff curtain prevented the Torch handle and cable from moving smoothly and would tend to turn or deflect the torch while it was moving - not good. I solved this by adding a tie point to the top of the torch mount, looped the cable back over itself to keep the torch end isolated from the tugging of the overhead bar. This also swung the handle parallel to the X Axis, giving me more room near the curtain.

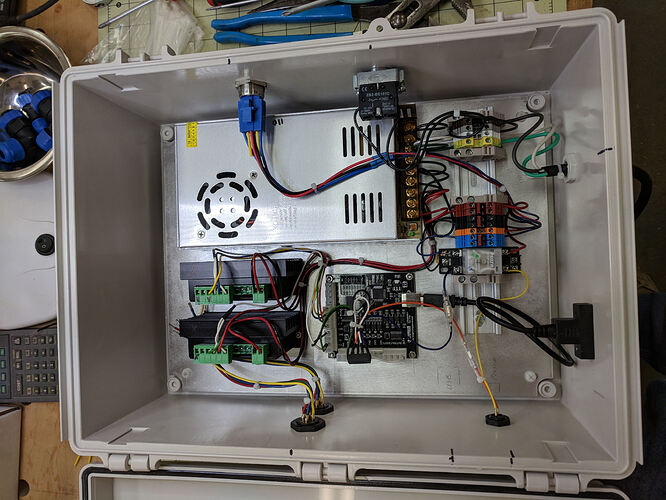

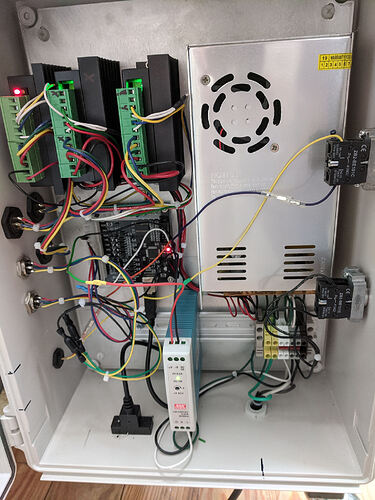

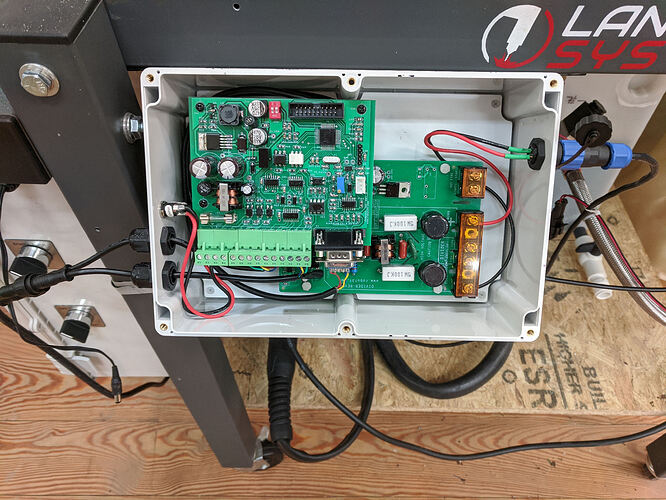

The third problem wasn’t obvious until I was cutting out by the Y0, X25 corner. The enclosure no longer had the natural ‘wind break’ of the Y rail to keep it from getting splashed and sparked. Consquently, it took very little time to convince me that I needed to replace the enclosure with a splash proof one. So… I bit the bullet and moved the electronic to a NEMA 3 enclosure.

So, without making this too long winded, here are the photos:

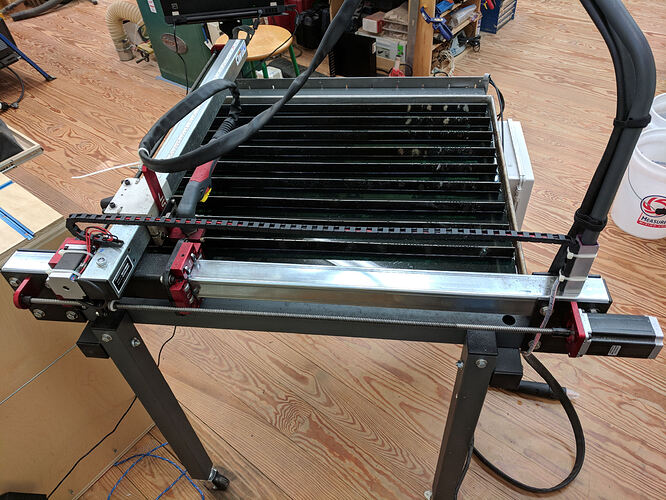

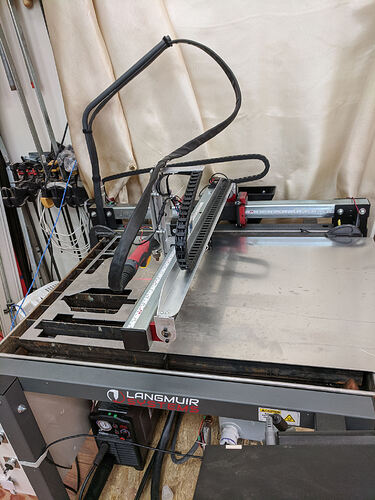

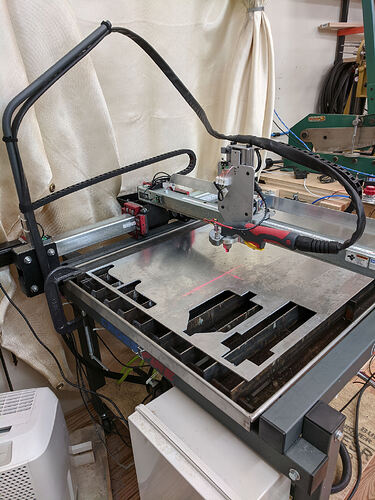

Front Views of the setup with Y at the two limits:

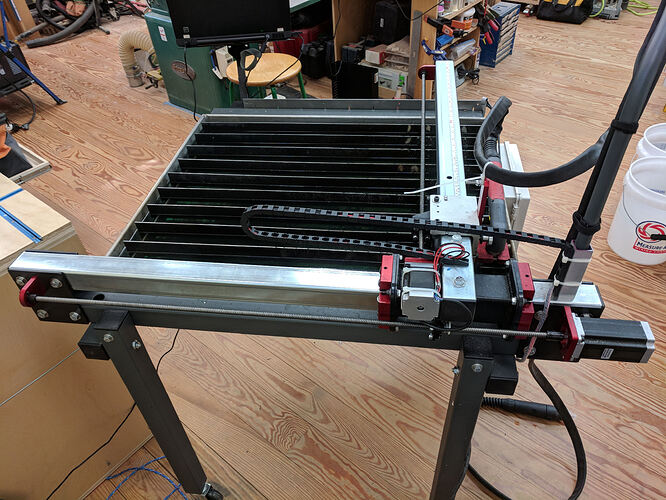

Back Views showing more of the drag chain detail:

Enclosure inside: