Having read this thread and seeing all the action with the Pro, it was very clear to me that CF original really needs a Z Axis and possibly THC. Inspired by @Dicky 's work and @Burgs04 original work, I decided to move in the direction of, at least, adding a Z axis to my 2x2.

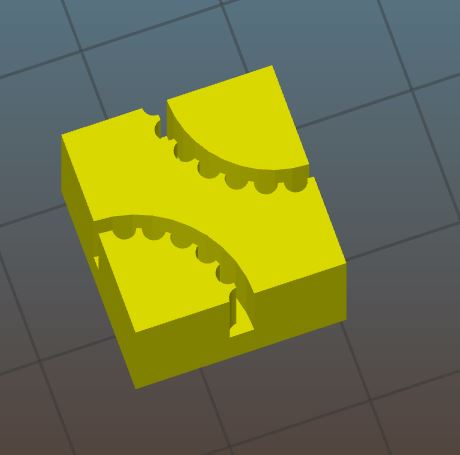

I didn’t care for all the weight of the Z motor & drive being at the top of the gantry so decided on a belt driven setup where the Z Motor is supported by the top of the original Gantry bracket and the Z Gantry travels on Openbuild’s V-Slot linear rails. The belt is a standard 2mmx6mm GT2 type strung between the drive pulley on the NEMA 17 stepper and an idler pulley at the top. The belt is bound together with a 3D printed clip that looks like this:

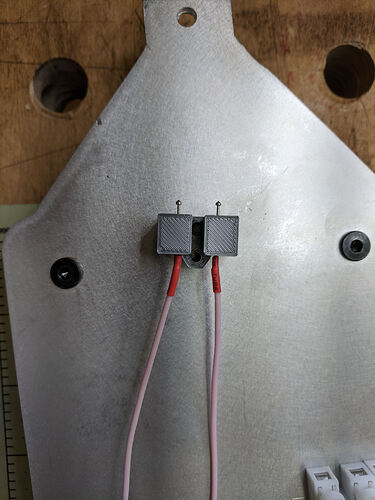

This serves to not only tie the ends of the belt together, but forms the lower part of the floating switch attached to the gantry plate. The switch is also 3D printed and looks like this:

There are two contacts made out of ‘pogo pins’ which are used in electronic test fixtures. The pins are spring loaded and the two pins support the weight of the Gantry and Torch. The belt clip is covered with copper foil and makes the closing side of the switch. When the gantry is lowered into the workpiece, the gantry stops moving and the belt clip separates from the switch contacts. Easy peasy!

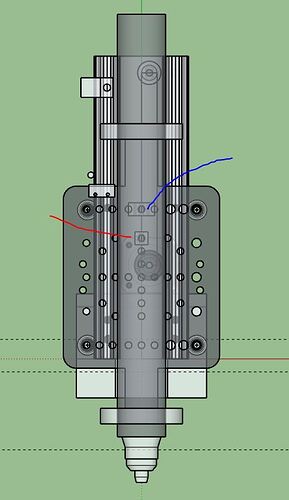

Here is the xray view of the design with the red line showing the belt clip and the blue line showing the contact block.

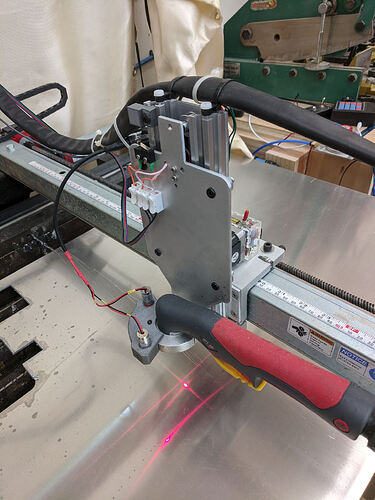

Finally, here’s the whole smash in the homed position:

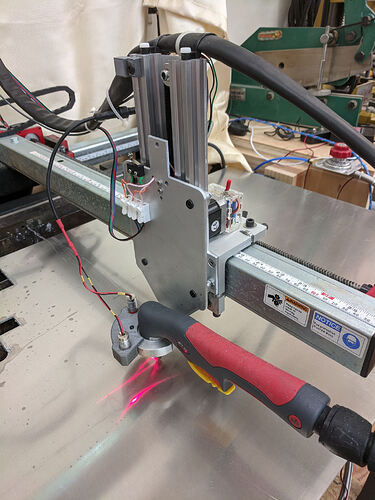

and at the pierce position…

Note that the cabling is not final, I’m debating whether to keep the cabling supported by the torch cable support or add drag chains… the jury is still out on that question.

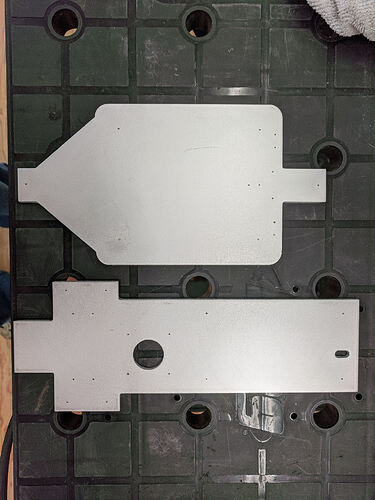

As a bonus, in trying to decide how to drill accurate holes for the gantry (especially the wheel posts) I experimented with ‘marking’ the hole positions, rather than cutting them with the torch. This turned out much better than I expected as shown below:

There you have it! My first experiments cutting with the Z axis were great! I did some learning on the first set of cuts, mostly related to pierce timing, etc, but I think I’ve gotten the best cuts, at least in steel, that I’ve ever gotten.

If you have any questions, as always, ask away!