If you run this gcode with FireControl:

cut height test.tap (224 Bytes)

This will run the table/torch as if it is going to start a cut. It will go thru the IHS to determine the surface of the metal and will allow the assumption of the springback to be set at 0.020 inches.

It will then set the torch at what it expects to be 0.060 inches and without firing the torch, STOP.

You can now measure with the feeler gauge to see what your cut height, in reality is really being set at when you thought you had set it as “0.06 inches.”

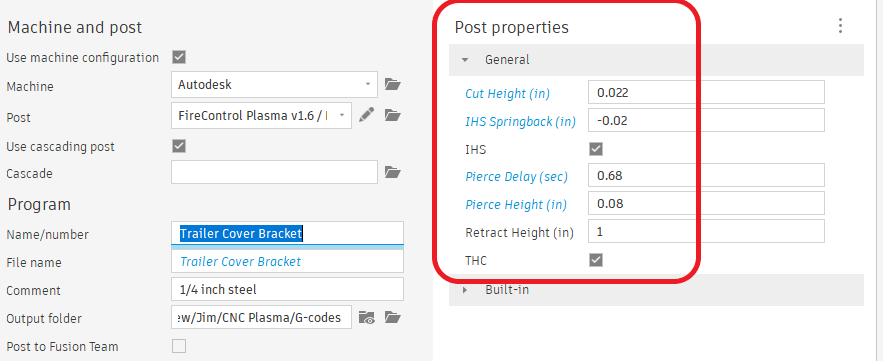

Now make the necessary changes on your CAM during post processing.

The springback determination is complicated by the reaction of your specific table. If you want more detail on that, here is a good read:

I started out with a cut height of 0.105 and this is how I ended up changing it in post processing to get to a cut height of 0.059:

Don’t use my numbers. Do your own independent testing with cut height and springback changes. Do a test run with a real test piece. To stop the torch and keep it at the same position, simply press the space bar with FireControl. Measure distance of torch to metal.