I calibrated the cutting height for my Crossfire Pro this weekend and I thought other folks might be interested in what I found.

First off, I had never calibrated my cut height previously in any way. I never thought about it, I guess my excuse would be “doesn’t the initial height sensing and torch height control take care of all that?” I think the answer is two part:

- the initial height sensing (IHS) does take care of that, but it makes an assumption about how much backlash there is, and that might be wrong for your particular machine

- torch height control (THC) is completely separate from IHS and is about what happens (or doesn’t happen) dynamically while the cut is being made to adjust for irregularities in the material being cut

Since I do all of my regular cutting with Fusion 360, I figured it would be best to take some G code from there and see what it looks like. Here’s the relevant bit where it probes to locate the material:

G92 Z0. (wherever the torch happens to be, call that Z=0)

G38.2 Z-5. F100. (move the torch -5 inches in Z at 100ipm, stop on contact)

G38.4 Z0.5 F20. (move the torch 0.5 inches in Z at 20ipm, stop on contact break)

G92 Z0.

G0 Z0.04 (IHS Springback + Backlash)

G92 Z0.

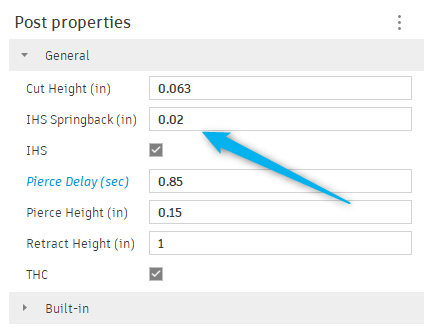

So the first few lines do most of the work, then the 5th line accounts for the difference between what we wanted (the exact height of the material) and what IHS actually did, due to springback, backlash, etc. In this case it says “move the torch up .04” and then it will be at exactly zero." If you look at the settings dialog when you run the postprocessor in Fusion 360 you’ll see:

which by default specifies an IHS Springback of .020", which is not the same as the .040" in the G code. I did experiments with changing the springback specified in the dialog, and always got a consistent extra .020" in the generated G code – for example, if I specified springback of .037 in the dialog I’d find .057 in the G code. I’m not sure what that’s about, but as long as you take it into account ![]()

I took the G code from one of my programs and cut it down it to include only the first height probe and no cutting at all so that I could just calibrate my IHS springback without having anything else going on.

(v1.6-af)

G90 G94

G17

G20

H0

(Probe it)

G92 Z0.

G38.2 Z-5. F100.

G38.4 Z0.5 F20.

G92 Z0.

(G0 Z0.04) (IHS Springback + Backlash)

G92 Z0.

G0 Z0.063 (Cut Height)

M30

(PS40)

After some fooling around I found that the correct springback setting for my table in the G code is .009, in other words .031" less than what I had been getting by default. Put another way, without doing any calibration I had been specifying a cut height of 0.063" but was getting 0.094", which I thought was pretty surprising.

Wrapping this up, my final setup is to tell the postprocessor in Fusion 360 that the IHS Springback is -0.011 inches, which results in an actual springback compensation in the generated G code of +0.009 inches.

I hope this helps somebody else out!