Oh yeah, trashed my OE pan a while back.

I have a dead thread here somewhere with the evolution of stanchion risers and my 3" deep, oversized water pan (I also now have 36x48 cutting area, working on 49)

Oh yeah, trashed my OE pan a while back.

I have a dead thread here somewhere with the evolution of stanchion risers and my 3" deep, oversized water pan (I also now have 36x48 cutting area, working on 49)

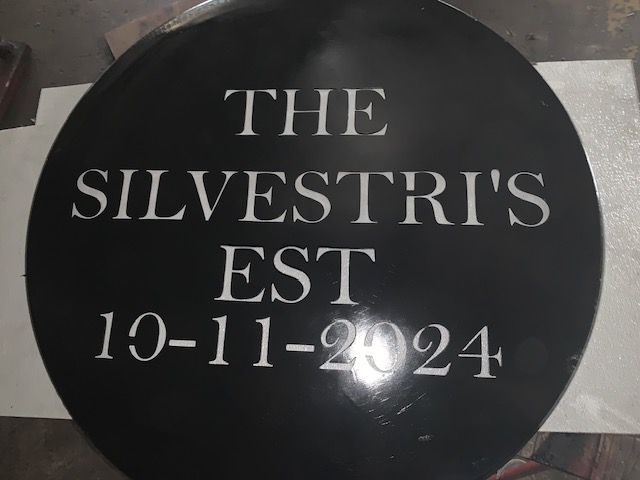

I am still deciding if I should use the solar back lit lights. My oldest daughter is getting married soon she wanted a yard sign. I still have some time to spruce it up. 36’ round used trowel pan.

Miller 625

40 amp 85imp

hand torch

Very little slag, but seeing that the metal is the used trowel pans and they have some rust on the backside I don’t know if this is affecting the cut quality or not. Raining today in southern Wisconsin so this is what I did.

I took an older Hypertherm Powermax 45 in on a trade for a truck I was selling. Not going to say what I allowed on the trade for fear it was too much and I’d just as soon not know ![]()

It has an inspection tag from 2009 on the bottom but hasn’t had a lot of usage. i know both previous owners, one of whom purchased new. Came with hand torch only.

I’ve gotten pretty comfortable with my PW Cut60 with machine torch and I get good results. I’m in the decision making stage on whether to jump in the $$$ pit to set this one up on my table. I know, superior results, longer consumable life,… but I just make a few signs for hobby. It’s become rare for me to have any cuts bad enough that I waste any steel.

My question is has anyone seen an adapter to connect a euro style machine torch to an older style Hypertherm cutter? Grainger has some but not listed for Powermax line.

Edit: I know this is not the best idea for several reasons. No need to lecture me. Just not wanting to spend $1000 on a machine torch to cut a few signs. I’ll likely just use hand torch if this idea is not feasible/no adapter available.

Pic of the port on the Hypertherm?

Not saying it will anytime soon, but a lot of these 45’s the board is going bad over the last 2 years. Hypertherm does not have them as far as I know and if you can find one be prepared to pay for it.

@mechanic416 the age of the unit is one of the reasons I really didn’t want to consider buying a machine torch. You just confirmed my fears.

The other reasons for my seemingly silly desire to use a non-Hypertherm torch on a HT unit are: I have gotten use to having an untethered hand torch available for other tasks; and, I want to give my PW Cut60 to one of my nephews and he will only need the hand torch. So, I’ll be left with a Hypertherm 45 with hand torch and a PTM 60 torch. The PTM becomes useless, and I have no untethered hand torch. The type of CNC I do doesn’t require really high level of performance, so to keep the hand torch free I’m willing to sacrifice a bit of performance if there is an adapter I can try.

Hope that logic seems close to sanity.

You do know once you rewire your Hypertherm hand torch for the table it won’t work as a hand torch any longer.

No there is no adapter for the PTM60 to Hypertherm. And I do not carry the machine torch ends.

Well why not?

Okay. Thanks for the input.

My whole goal was to keep the hand torch as a hand torch and re-use the fairly new PTM 60 on the table. Guess that might not happen.

Because I may get a call for one a year. Also why would anyone want to put a Tecmo/Loncoln torch on a Hypertherm. ![]()

@Wsidr1 would.

Sorry 14 gage custom programing in sheat cam perimeters

Worked on the garden shaman sculpture this afternoon. Got his left shoulder cut, bent, tacked and it looks great!

Cut video is here.

https://www.instagram.com/p/C82nOPwuAWI/?igsh=MzRlODBiNWFlZA==

Looking good Craig!

Did you use your English wheel (or whatever it is called) on forming that?

Those cuts are very interesting to achieve that shape…never would have guessed.

Thanks, his shoulders are too small for the English wheel. I did use it to form his body panel curves.

I don’t believe that the weld on that 8 inch I beam is going to come loose.![]()

W8x15?

How many passes on that weld? It’s huge!

I hope not, it is five layers of weld… roots over roots with cover. On both sides, so that’s 32" of weld. Plus the tops and bottoms, so another 24". Lotsa inches of weld.

BTW, no one EVER compliments my welding skills… ever… lol. Thank you big daddy!