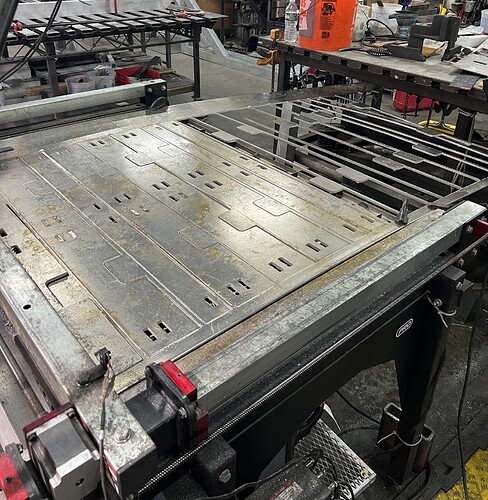

First job on the new hypertherm 45p, also first aluminum job that used it, cut 120 brackets out, used 4 full 4x8 sheets of 1/4" aluminum, was a nightmare and definitely proved I can’t realistically use this for production on that scale in aluminum, was just really nasty. Apparewntly I forgot to take a picture of the stack of brackets, but heres a sheet partly cut and the mountain of aluminum left with once I cleaned out the table.

That’s a big pile of progress.

Hmmmm, progress is now measured in piles? ![]()

Yes, I personally couldn’t sleep at night with that progress in my pan. But I get it.

I clean my pan daily using a buckethead wet/dry vac. I’m sick, I know.

i mean this was 2 days of work, not like I was cutting for weeks with no cleanup. And part of me needed the visual mess to show my boss what a nightmare aluminum production at this scale is to make the CNC guys suck it up and cut aluminum on their router that is perfectly capable of cutting aluminum. They complain about having to replace the SPOIL board once all the lubricant seeps into it. ![]()

So are you just dumping all the water that comes with it? I was worried about running through my greencut too fast if I had to keep replenishing and remixing it so fast.

No, I have one of these under my table.

Vinager. And sometimes muriatic acid, i prefure 35% AND 45%

I got the 1st layer of a new sign cut this evening. A friend who retired from Toyota a couple months ago is going to do some auto repair in his new garage. The total height there is about 40".

This is 16 gauge. Going to cut 18 gauge back plates for both pieces. He is going to paint it. I’m happy about that!

Brett, I know what you mean about the finishing/painting phase. I got pretty good with oil based urethane finishes. My wife just would gripe “I can smell that!”

So I decided to try water based urethane when I made a sewing cabinet for my daughter as a Christmas present. I was never so frustrated. If it is too warm, you get all sorts of gritty surface, uneven surface as it does not self level and cloudy spots. If it is to cool you get runs and drips.

I refinished that cabinet seven times. Sanded all the way to wood three times. By the time I got to the second gallon, I finally got a technique that worked.

I have tried that in the past and had the same problems. After talking with a rep he convinced me to switch back to oil based.

I tried it in two different brands same results

I have found one very good use for the satin acrylic urethane. My daughter loves painted wood ![]()

But painted wood doesn’t have the durability of urethane. So I spray a coat of the water based urethane over the paint. It does not leave the yellowing effect that oil based urethane would. And it is barely noticeable.

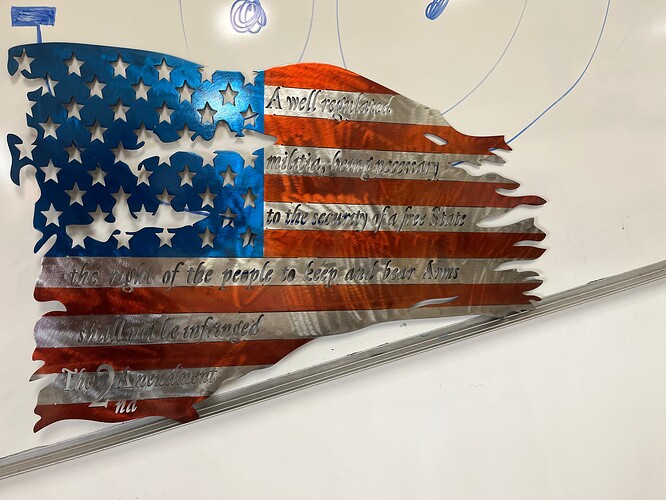

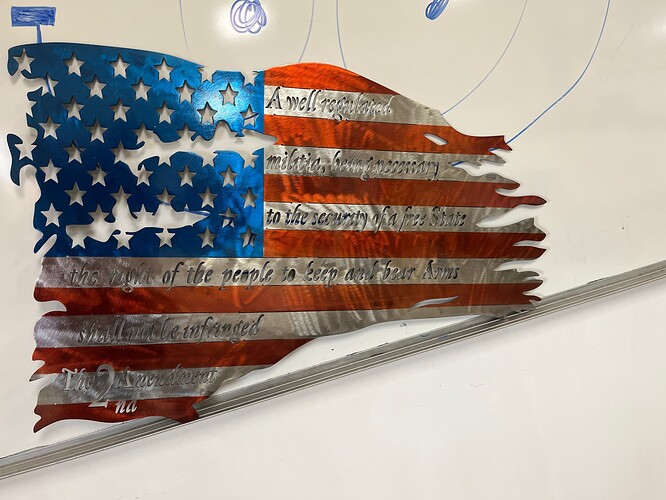

I have been really busy this time of the year but here are some of our better ones from the last couple months.

Glad to see you back! Love the flag. How big is it? Are you going to make it available? I’d like to cut myself one of those.

I got my background pieces for this one cut this morning. Had to get up at 5:30am to get it done. Promised the guy I’d deliver it tomorrow, and I had to take father to hospital this morning,…so no other time.

Few projects in the works

1 inch thick eye ends for a screw jack.

Hypertherm 1650 at 100 amps. One Flat edge with the Burr on the bottom was cutting too close to the edge on a piece that already had a little bit of a taper on it. Very little dross, taps off with scraper super easy.

Now why can’t I get my holes with that minor of a taper? That is .0625 over 1"

Mounts for the screw jacks out of 1/2" @ 85a

Plates for the screw jacks

This is the “Umbrella/Sunshade” for the top of our laser prism that I asked for help with a while back.

Made the bottom red mount for the mast too.

I made a tool for my Mag Drill. Slides over the front of it, and little hole in the center is the same size as the dimple when I mark my holes positions. Lines up the drill within a couple of thou of where the hole needs to be given angle of view and shadows.

More brackets out of 1/2". All of these popped right up, and little to no dross.

Unmolerstered - no dross chipping yet.

About 40” wide, it is a file I purchased off of Etsy, so I can’t post the dxf, but it was only a couple dollars.

Do you elevate your metal to keep from burning through the water pan? I thought 100amps and ???psi would create a danger of that.