Had shut everything off, ran some errands, then thought to myself…maybe I should cut something else ![]()

Kwikfab, Very nice work, my friend

Thank you!

I don’t often cut and/or weld so when I do, it’s always exciting (even the small stuff).

WHAT?! You mean to tell us that we are not “your everything???” Well that just hurts… ![]()

![]() Looks great. Both of them.

Looks great. Both of them.

That is superb!!!

How long did that take to cut?

About 20 min pause between cuts ![]()

That’s a real beauty! The details in the feet and head are awesome.

Will post a clean pic and etched pic

Thats bad ass! Did you draw that? what ga sheet? fine cut?

Very nice

Ahhh the elusive round hole

@holla2040 is lying. He’s got a laser cutter in that shop!

Has to be. Best I ever get is a teardrop, or ugly tapered on 2/3rds of the bore.

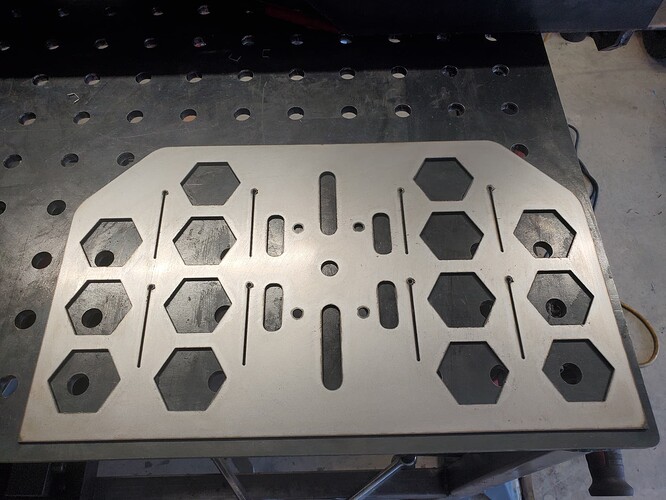

Naw! He did that on his plasma table. These are 3/8" holes on .25 inch plate that I had cut out for my rocket stove. Some are not perfect but this is looking straight down on them. And this 3.7" x 6.7" piece was cut out of a 4" wide strip of metal so I can’t say that it was really held solid during the cut.

I wish I could get better than a 18% success rate.

Aah, come on guys, you think I’d get a laser and not tell you?

Plasma Proof!

https://www.instagram.com/p/C7GIdQ8O1lg/?igsh=MWttc2cyOXU1NTQ5aA==

BUT, we’re seriously considering this

I am not saying this is what is happening with you, but:

When I first started with my table, I had the ugliest holes anyone has ever done. Squares, rectangles, straight lines and letters were fine. Then one day one of my lead screws fell out of the coupler attached to the motor. After I reattached, tightened with blue loctite, my holes were like in that photo every time. Holes that are 1/2" or larger are even better.

I cut my .265 and .385 holes on this 11ga very slowly, probably 25 ipm.

I think that is a very good reminder. Slowing down the cut really gives the chance to clear out the metal all the way to the bottom but it will leave additional dross.

I always say “if the dimension is more important than the aesthetics then you are going to need to put up with a little more dross.” Now I am paraphrasing myself ![]()

But it won’t be the hard rolling dross. It will be the kind that the fireball tool works great on: just a quick slam and it pops off.

If I was doing an artsy thing or sign, I might allow the bevel on small inside curves just so I didn’t have to remove dross from a delicate area.