It has to be a vest cut out on a LS table to count though.

You first!!!

I would but my skill level is strictly hack, 2-D sign making.

Someone could 3D print them for us

Many times on the FB group, I’m brushed off completely when I tell people to dial in their setup.

They only hurt themselves.

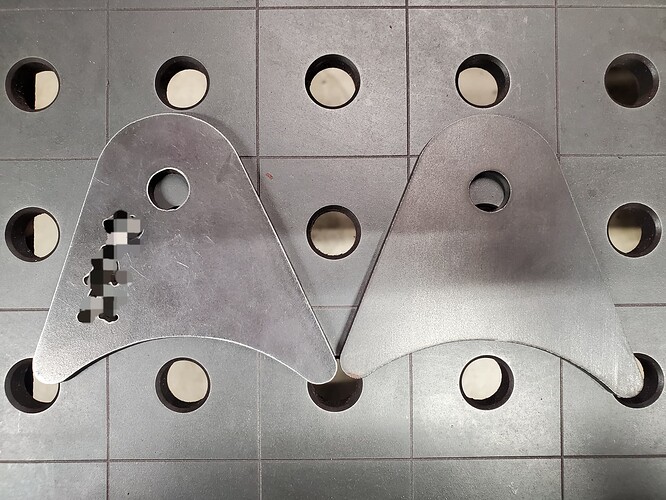

Customer provided part on the left, cut on a $15k table and Hypertherm 45XP.

My repro on the right, cut on a $3k table and the same Hypertherm 45XP.

Drawing has something to do with it as well as you can see the top radius looks like it was done using the spline feature or similar. The hole is really oblong too (more noticeable in person).

And my part.

First try, got it damn near perfect. Call it 99.9%.

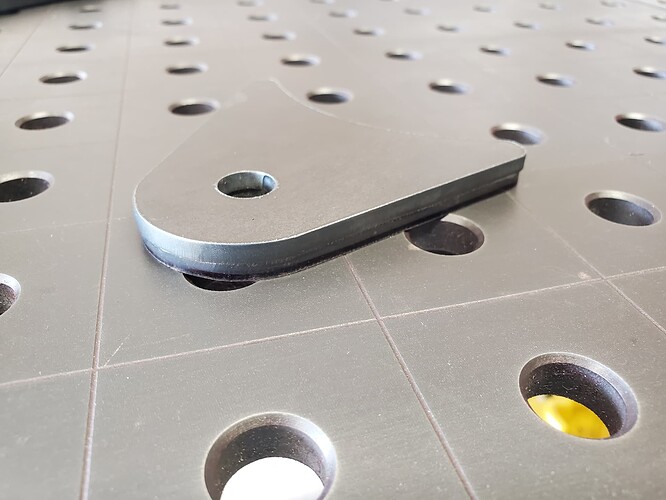

Here’s the second part provided - holes are all jagged and oblong.

And my cut out, on the right.

The important thing to note is that the small holes were done at 2.53" center to center. Before I drew them out, I asked the customer what the specification needs to be and he stated 2.48" so I made the adjustment as needed.

Overall dimensions are about 99% again, but with correct distance between the holes as well as cleaner cutouts.

Kid just woke up so I’ll knock out the remaining parts later.

Bigdaddy’s not allowed on Facebook. ![]() But, that is a perfect copy.

But, that is a perfect copy.

Nice copy. Their holes look like they might use a 90 degree lead-in causing a little nick (Sorry Knick…not intended!).

I think you are really liking your Hypertherm now??!!

For sure the wrong lead in, but to use the wrong lead in for such a long time on all the parts you sell?

Crazy. It would’ve bugged the hell out of me to fix it.

I know your question is a separate one, but even the PrimeWeld would’ve got me the same cut quality I have now on these parts!

The Hypertherm Finecut setup though is where it really shines!

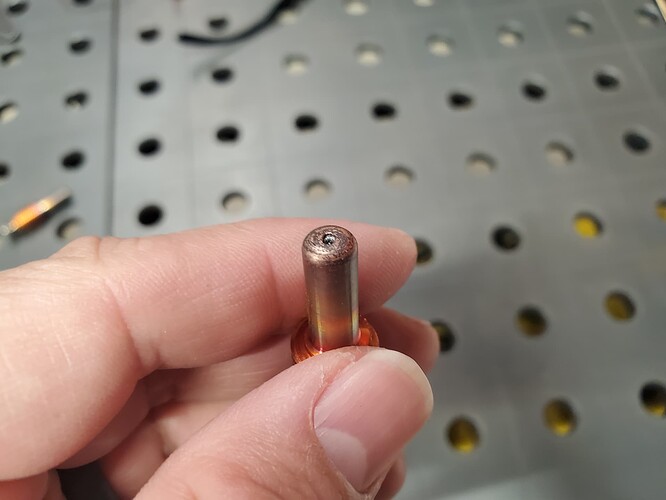

Weird thing is, I had to pull my finecut consumables off prematurely at only 451 pierces.

The nozzle looked good still -

But the electrode was definitely shot -

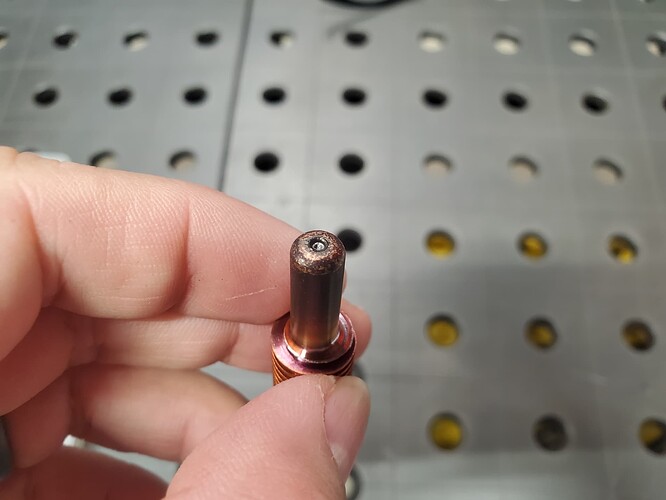

Yet here’s another electrode used with regular mechanized consumables with 1,000 pierces -

The hafnium is worn a lot narrower (naturally, cause of the smaller kerf) but even deeper at half the pierce count -

The first 196 pierces were all used on 16 gauge at 32 amps and only 0.5 pierce delay.

The remaining 255 were also on 16 gauge, but at 45 amps and the same pierce delay.

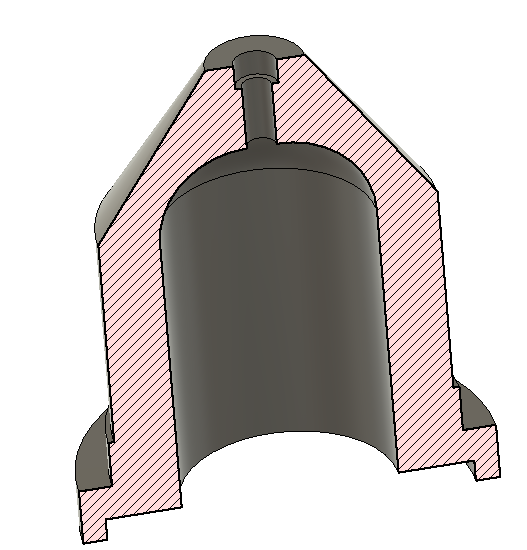

Tin pointed out something about the normal tip/nozzle: there is a step inside. So that nozzle can wear and not look like it is wearing on the outside but I would imagine as it erodes away, there is some degradation of the cut. This is the 220941 nozzle. I could not find a STEP file for the fine-cut 220930 so I don’t know if it has the same design.

Yeah the nozzle itself, if I chopped it in half, looks thicker at the opening on the 220941 for sure.

The 220930 is chamfered at the opening.

Crazy to think those small differences can half the life of an electrode though, at least on my setup.

It might have been from this post when we’re exploring them nozzles with a microscope.

Also had a post about hypertherm’s opinion about when nozzles should be changed.

dialed! nice work.

Very nice flag. Didnt see it on Fireshare. Any chance you would share the file??!!

Thanks

Any chance you could share settings? I have the same setup and I am having trouble with fine cuts…

If you have not already, start a new thread @Amyejohn about you issues. Do some searching on the forum and you may find your answer.

Sticks has a good suggestion. If you would like, one of us could split your comment out of this topic and in the new topic and you could explain your setup and what is going on.

Dylan, the user you replied to, has only visited 2 days in the last month. He used to come by regularly but not sure when/if he will be able to directly reply. He would need more information as well.

Welcome to the forum.

Someone in the FB group recently cut himself out a stool.

Been meaning to do this for over a year now so figured, why not start.

Cut a mock up leg and template yesterday, along with stripping the backrest from a 2013 soft tail sissy bar.

Acme lead screw arrived today and I realized, I should probably use 1.75" round I’ve got on hand versus 1.50" round I wanted to go out and buy today.

Going to have to cut out a new template with a larger center hole.

The flag came out amazing, what did you put on it for a finish? is this file available for anyone to use? Great work!

Thanks!

No finish, it’s raw steel right off the table.

Can’t share the file though. A member on another group made it, and being a non-artsy type he actually drew up every single letter (tracing an image).

He did it to make a sign for a disabled veteran, and happily shared the file with me being one myself.

Out of respect for his work, I won’t share the file or even sell any signs cut from said file. This is just a personal piece!