So there I am needing some holes in some 1/4" mild steel for a project I am working on for my hoist.

I bought the metal, “pre-Langmuir”, and I wanted to use it.

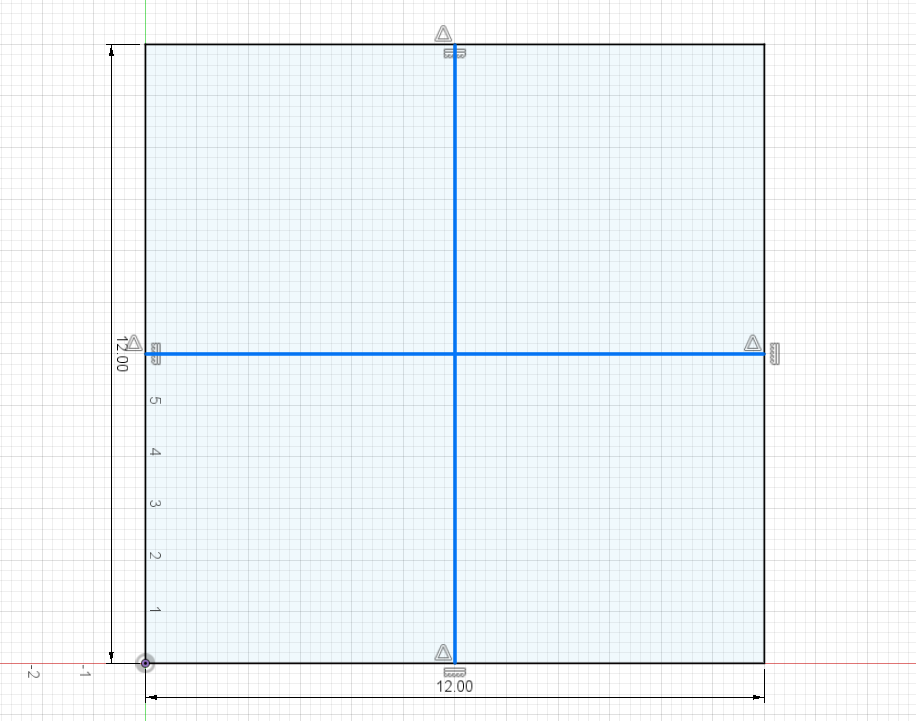

I needed 5 holes in each plate, and all 3 plates should be the same. One “big hole” (1.5 dia) in the center, and 4 (3/8 dia) holes at the mid point of each side of the square.

Well I draw it out in 360 and run into all kinds of problems, mostly having to do with, for some reason, not being able to turn a “cut line” into a “construction line”.

Well after some “jacking about” I finally get what I thought was a “construction line square” with the 5 holes" in place.

So now how the hell do I “place the metal properly” so that the holes end up in the right spot?

Well my dumb ass decides to ‘dry run" the program, then shift it around, then "rinse and repeat’ until I get it “good nuf”

Hit dry run, and “reposition it”

Again hit “dry run” and reposition it.

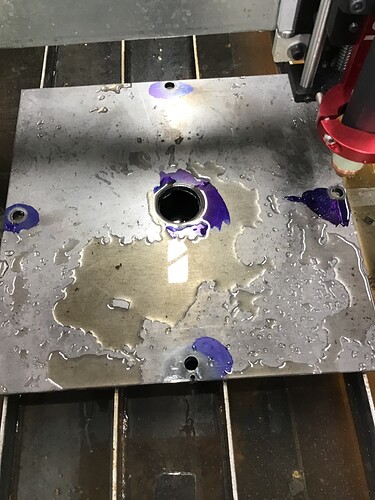

Then I was “ok with it” and hit “run” and to my dismay, I FORGOT TO HOOK UP THE DAMN GROUND CLAMP!!!

Well the cuts were of course all “jacked up” but I was able to stop it relatively quickly’

So I take my “Mulligan” and hook up the ground.

I have no idea where the hell that little “divot” came from, but it’s not a big deal in this project, so I call it a “win”

Now here is the hard/interesting part. I have 2 more plates that need the same holes.

I can not figure out for the life of me how to do this, so i go “old school” and just use ‘witness marks’ on the plates and the table.

Well it aint 'NASA Accurate" but its ok, I guess.

Any suggestions on what to do in a situation like this next time?