If you are using a Razorweld Cut 45 check your retaining cap. It shouldnt be too tight. When too tight it causes arc loss. Also make sure the connections are kept clean on the cap ring and the 2 pins in the torch

Ok so sounds like you had interference and that is now fixed by this mod (since you can cut now with THC off).

If you aren’t getting arc voltage displayed in FireControl, it could be that something isn’t connected properly. Follow this troubleshooting guide to help determine where the issue could be: THC Arc Voltage Troubleshooting Guide

Can confirm, mod works for me too. It will still sometimes stop firing in the middle of a cut but the table will still move and it doesn’t freeze up FireControl

Yeah, what cutter? If it’s the RW, I had the same experience. Turned out to be an issue with the internal air reg even though everything pointed at EMI and arc faults. My air was set at 70 and dropped to 60 during cuts, causing arc loss errors as it shut off the arc. Solution was to crank it up to 82. It only dropped 2psi to 80 after that and cut like a champ.

I’m going to do the mod. I’ll post a video.

I have had only a couple freezes, but I’ll be doing the mod. I’d love to run a longer usb cable, has anyone added say, a 10 footer and had any issues?

As promised. Here’s the video. I hope it takes a little of the mystery and scariness out of the process. It really isn’t that hard or possible to screw up.

My husband ran across a video on You Tube ! Just put up the other day! By ManCraftingTM

https://youtu.be/wn12W4AdaDM

The video is helpful. Lol. I just following langmuirs instructions above and took needle nose pliers to the board and that inductor crunched out.

My soldering job was even worse. Still need to fire up the table and verify it worked…

I was nervous doing it, so I mailed it to Langmuir, its it’s on bbn it’s way back now!

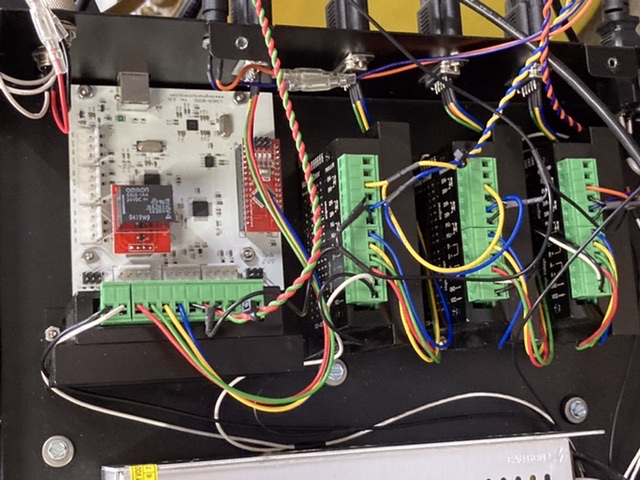

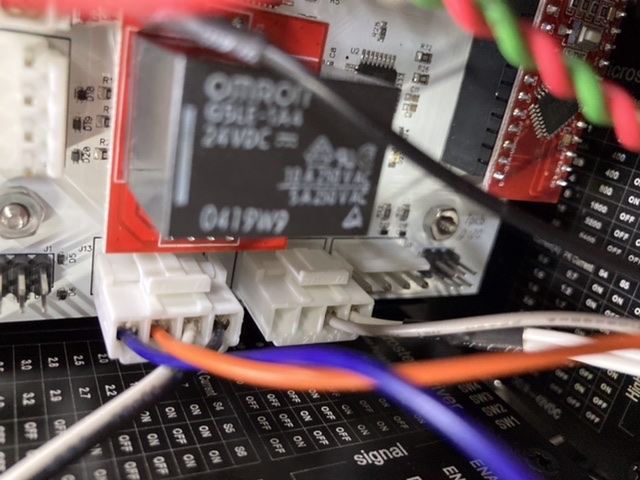

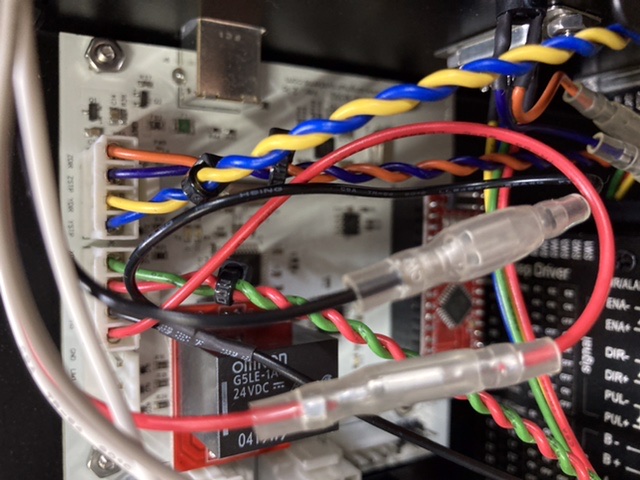

The video from Mancrafting is very helpful. For those who have thought about trying this without dismounting the board, I just did and it was no problem. The sequence was remove cover screws, unplug four connectors, pry inductor loose with long needlenose pliers and dab on solder. The hardest part was getting my 55 yo eyes to even see the danged L1 label. I attached some images in case someone wants to follow along. They are: (1) & (2) the four plugs you will disconnect for access in their correct orientation; (3) the view of the inside with the wires tucked out of the way; L1 is near middle on the right side ; (4) an image of the pliers that worked (third pair I tried) and (5) a closer view of L1 inductor removed. I suggest starting your bridge on the top, so that gravity works for you.

Well, I tried, but the images are all whacked. I don’t know what happened. Point is that it was a very easy job. Sorry for the messy post, folks.

I was thinking the same thing, it could be done with the board in and just unplugging the harnesses. I took mine out just to get a better position to solder. I don’t think it made a difference for me.

Only my second time soldering, but apparently my deep TIG incompetence prepared me well for a process that requires touching filler to heat source. At least for a rightie, access is really pretty clear.

I did this over the weekend and it seemed to work put have not run the torch much waiting for some new tips.

Did the process help your issues?

So far, it jogged great so I didn’t lose continuity or anything like that. I have a really noisy cutter and plan to test with it right under the table tonight or tomorrow night.

Just completed this tonight. I have a heavy Cutting weekend planned, I’ll report back . Hypertherm 45 sitting 12” away. I’ve had a couple strange things happen previously on start up while jogging the machine. We shall see if this was the cause.

Fixed my issues. I had it happening randomly. I had three chokes (one looped two molded) on my LS supplied USB cable.

Now I am running an Amazon basics 10 foot USB cable with two unlooped clamp on Amazon sources chokes. Not issues at all. Very happy.

For reference, my Pm45Xp is 2.5 feet from my motion control box. Laptop was plugged into the same power strip as my motion control box also.

11 30”tattered flags with script Along with several other pieces, not one hiccup. Laptop and control box on the same power strip. I think the Langmuir team nailed it.

The fix is real. I went from USB isolator, 6 chokes and my cutter across the room to being able to cut with my cutter very close to the table and no chokes. Still got 99 problems, but noise ain’t one.