Since beginning the delivery of CrossFire PRO machines, our number one priority as a company has been to chase down issues and offer permanent solutions to them. This is evidenced by our frequent updates to THC firmware and FireControl to fix known and reported bugs and also to add functionality requested by the community. The total number of reported issues has plummeted in the last few months which we are really proud of, but we are still not where we want to be.

There are two issues that we have been seeing more frequently than we would like to fix. One of them is FireControl launching issues which we are working on intensely to solve. The other, and what will be discussed in this thread, is the interference/EMI problem. For those not familiar with this issue, check out this thread: FireControl Freezing During Cutting & How to Fix it! - #74 by CadDaddy42

After delivering all batch 1 and batch 2 machines, we found that about 70% of users are able operate without any clip on chokes. Approximately 25% need 2 chokes with the remaining 5% needing two or more. Obviously this ‘solution’ is something we have never been satisfied with so we started really looking into our board design to figure out why it is so sensitive to EMI and what we could do to bolster it.

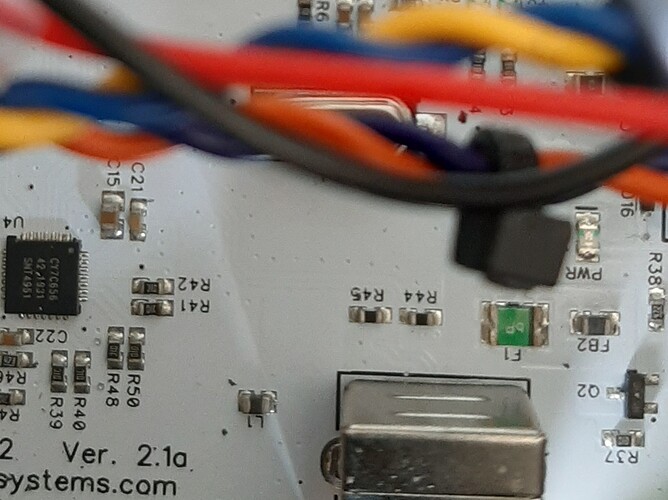

After testing a lot of different theories, we found that a single SMT inductor was the source of the problem. For those not aware, the D+ and D- USB data lines are usually pulled to ground with weak pull down resistors. This is to ensure that the data lines aren’t ‘floating’ which is good for EMI resistance. An inductor is placed in series between those resistors and the ground plane which follows standard USB guidelines. That inductor is great for ‘trapping’ noise that emits from the board, but it turns out that the inductor acts like a receiving antenna to funnel noise emitted from the plasma cutter straight to the data lines via the pull down resistors. Noise on data lines is BAD.

Through testing, we found that removing the inductor and soldering a short between the solder pads dramatically improved the resistance to EMI. We have an AHP plasma cutter that is a particularly noisy emitter that requires the use of multiple chokes (3-6 depending on the computer that is used). By shorting the inductor, we are able to run the AHP using a cable that not only doesn’t have clip on ferrites, but also does not have molded ferrites either.

We will be performing this modification to all of our motion control board inventory so that future customers do not experience this issue. A 0 ohm resistor will replace the inductor on subsequent manufacturing runs.

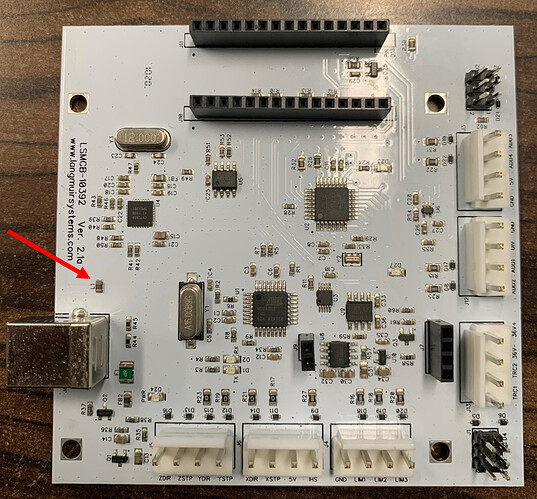

If you currently have a batch 1 or batch 2 machine and wish to make the system more robust to noise, we strongly recommend performing the mod as follows:

Step 1: Using needle nose pliers, remove the inductor labeled L1

Step 2: Solder a short (aka a solder bridge) across the two pads

Step 3: Reinstall board.

Since we have only tested this on our shop, we would love to hear the communities experience with this modification. If you are having interference problems and don’t feel comfortable doing this mod on your own, feel free to send us your board and we will do it here.