If it works you know the motion control and cutter are working. then you can focus on the THC signal.

We didn’t run another cut with THC off after I saw his live voltage numbers. Went straight to the THC health check.

Prior to our chat he discovered his torch was a tiny bit loose in the mount and corrected it, ran the cut again and made it. So, that may have been a factor in earlier cuts. When I heard that I figured it was the issue. So on to the test cuts.

We verified cut high with the test file, it looked .02 high. He loaded my test file which should come in .02 lower and hit run, and that’s when I saw the live voltage. It cut ok, but the voltage was more than double what it should be. Something is definitely wrong. Live voltage was high from the moment the torch fired. No hunting around, very little THC activity.

You should try this @Bastrawn

Wouldn’t hurt. Run that same test file I sent you with THC off.

The piece that came off the table during the high voltage reading looked ok. Probably because THC sensed high voltage from the get go and just maintained the torch height. You see his earlier posts where he was trying nominal and it was dragging the torch. That makes sense because the voltage reading was so high.

If it works with THC off, which we know it will, what does that mean for the incorrect voltage readings he’s getting from the cutter and from the THC chip per the Langmuir troubleshooting?

Or try raw voltage.

Is it the hypertherm giving a bad voltage or the VIM.

At 145 posts on this topic lets not assume anything

Trust but verify.

But it does look like a bad VIM currently, at least on the DIV side.

I once had an issue with one of the THC wires were causing problems. Even with the THC off still problems. the wire was replaced and the problems stopped.

So don’t just run it with the THC OFF unplug it from the circuit too.

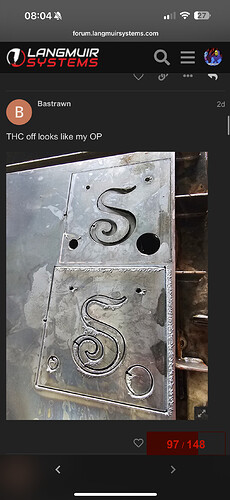

Here’s sticks request from post 13 about trying with the THC off.

I measured the voltage on pins 5 and 6 of the CPC

The idea here is that it’s functioning with every other configuration of consumables except for fine cuts because they run at about 45 volts less then other configurations of consumables?

So try running raw voltage from your Hypertherm and see if that solves the issue.

There’s a link in this post to how to wire your unit raw

There’s also a link in there about the add-on voltage divider board which goes into a lot of detail of where it is and how it’s hooked up. Including the part number if you require a replacement.

I had to buy voltage dividing board and add it to my 45 XP mine was not factory installed.

He did run it with THC off right after sticks asked him to.

It seems irrelevant to me if normal consumables appear to work without an issue when we have incorrect readings from the back of the cutter.

I agree raw voltage would be the next step. Or checking the internal divided voltage board settings like I posted.

Maybe Im off base, but it makes sense to work from a known point rather than speculation on prior issues. While running some cuts we found the voltage problem. To me it stops there until we are getting correct voltage numbers. No point in checking anything else until that’s rectified.

If it runs the program with the wrong voltage, and completes the cut, what do we learn if it completes the cut with THC off? Are we just checking for cut quality?

Since it’s wrong coming from the cutter, start there until the cutter reports correct voltage. But also, his equipment fails Langmuirs own tests according to their flow chart.

Yeah we are at 145 posts which means not everything is being read and retained, which is fine, we see this on the forum often. I’m just hung up on the data that is not subjective, the incorrect voltages.

So that it also does a bad cut with the THC off what does the divided voltage have to do with it?

Divided voltage isn’t being read by anything at that point with the THC off so wouldn’t it make the measurement irrelevant if the problem persists regardless whether you’re using it or not to control the THC?

it’s pointing to something deeper than the divided voltage board in that case.

I see the VIM being mentioned.

Was it ever checked for continuity? It takes 5 seconds (for divided).

Haven’t checked it yet. The troubleshooting chart doesn’t event suggest it based on the symptoms. VIM was my first thought.

@TinWhisperer i see what you mean, but you’d have to see the cut we made with my test file to see why I’m looking at it the way I am. When I said earlier it cut ok; there was just one spot that maybe needed the dross knocked off to see if it was smooth. There was no saw tooth anywhere, and the whole thing cut.

I hope for his sake I’m missing something. If it cuts fine thinking it’s getting 190 volts I guess there’s no problem using smart voltage. But it still fails the Langmuir tests on ref and gnd pins in the control box. And the cutter isn’t putting out the right divided voltage.

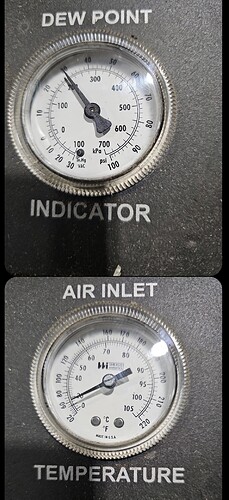

Here’ a Shot of the gauges on his dryer while it’s running. If this helps.

Weird being back on this side of a troubleshooting issue. Lol.

True, it doesn’t.

I only suggested it because I’m a fan of fast and free troubleshooting steps.

I’ve had my own VIM go out on me in the past.

You’re going through a lot to help, and that’s very admirable, but confirming something simple just to ensure it’s good doesn’t hurt either.

My brain gets hung up on absolutes. So I hear something for sure isn’t in spec, it must be in spec before I move on.

The people on this forum amaze me at times, and the energy going into this post shows it first hand.

My hats off too everyone in here trying to help. you guys are a RARE breed!

I couldn’t agree more. My head is spinning because this is kind of being battled on 2 fronts (Langmuir and Hypertherm). I have been in communication with both and will be speaking to Langmuir when I get home. I don’t think I will be home before Hypertherm is gone for the day so that may have to wait until 430 am in the morning. @brownfox has been incredible, totally a stand up dude willing to help and share his knowledge.

My point was with the THC off, was to remove the table from adjusting the cut height. To me, all those fine cuts look like it’s too high, whereas non fine cut nozzles will finish the cut with better results if still to high.

I have had the THC on smart voltage drive the height up and maintain at half an inch or more.

Update

I was able to speak with Hypertherm support, I got stood up by Langmuir support.

The dip switches on the voltage divider was set to 20:1. Changed that to 50:1. Support had me measure resistance between pins 5 and 6, my digital multimeter read infinity or open. He had me unplug the divider board from the main board and measure both directions - still infinity. I thought maybe the multimeter so I grabbed my analog megger, still barely registered. Neither of us could explain how I could read voltage across 5 and 6 when the torch is firing but it reads as an open circuit. He said the state of that circuit doesn’t change when power is applied. That’s conundrum number 1.

I put it all back together and did a straight cut test on the machine. DIV input cable (disconnected) read 2 Volts during the cut. Plugged the cable back in and ran the THC test, it passed 131.9 Volts. The test passed, but when @brownfox and I tested the THC and motion control board, they failed. Conundrum number 2

Up next:

I’m going to cut the test file that @brownfox sent me and monitor the voltage during the cut. I will stop the cut on one of the lines and measure the torch height.

What’s funny is, I was typing up a response earlier but discarded it because @brownfox mentioned the dip switches earlier.

If you bought the CPC kit (or machine) used, it could’ve been set for a different plasma cutter type.

But also odd that you’ve been running with regular consumables and voltage was never noticed or?