I like that you noticed that. It was on my list. I’ve used three different colors of dessicant so I wanted to talk to him first, but I think it’s safe to say those beads a probably spent.

Well, I would call this mystery solved, for the most part. But we need some more input.

I verified his air, routing, ect. looks fine. 7 PSI drop under operation. I declare, the air is fine. Dessicant refreshed. Even compared his consumables to mine right off my table. I feel like the high res photos make them look worse that they are. The trashed consumables make sense to me based on the following information about the live voltage.

Torch mounting height verified, IHS appears to be functioning as designed.

But, while cutting my test file with fine cuts and smart voltage, he was getting 190 volts. Definitely a problem.

Did not pause during cut to check height, could have done that, but the voltage was so high from the get go I had him do the THC health check immediately. Also makes sense given the torch dragging as he posted previously.

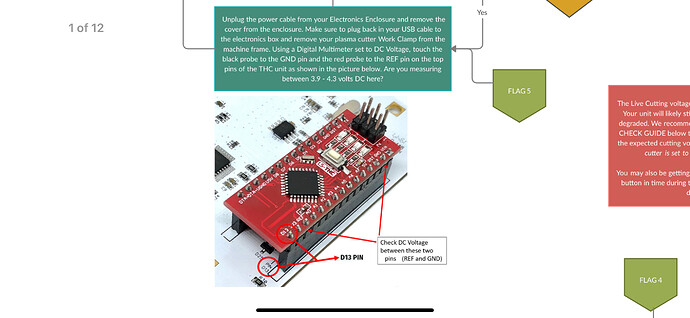

Ran a THC health check, 300v. THC cables verified in correct locations, and he’s using the supplied Langmuir cable. I suspect a bad VIM, but this may require testing off the back of the CPC port to verify?

No resting voltage.

I told @Bastrawn I’d post this and see what the group thought.

After comparing his consumables to mine, I’m not sure they were installed incorrectly. Why was the divot off center in that one electrode? Beats me.

@Bastrawn this is the next step according to the flow chart.

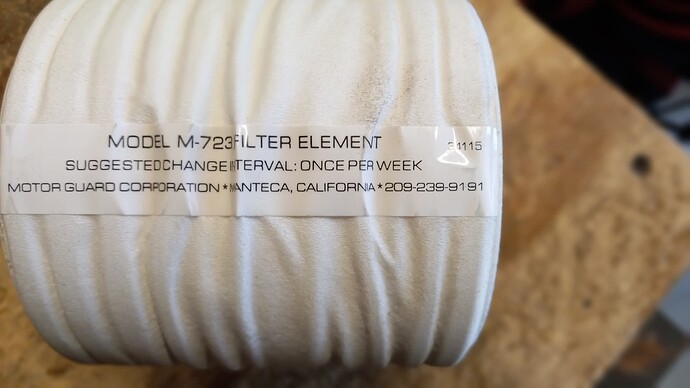

Good catch their @TinWhisperer. I will bet the Motorguard filter is also bad.

I had him open it. Dry.

Once you take out a Motorguard filter you have to replace it of it will never reseal and buy pass air around the sides. They also should be replaced every week…

Hmmm. What seal are you referring to? Something on the filter element itself? Like you can’t remove it from the housing once it’s installed or it’s trash after?

The manual says the suggested replacement interval should be several weeks in dry air situations and to check daily to determine change interval.

I can’t imagine there’s anything wrong with his air with what I’ve seen unless something is drastically wrong with his dryer.

What are your thoughts on THC causing the torch to drag, couldn’t that explain the trashed consumables?

Edit- this explained it well. I even commented on that. Lol. It was a while ago.

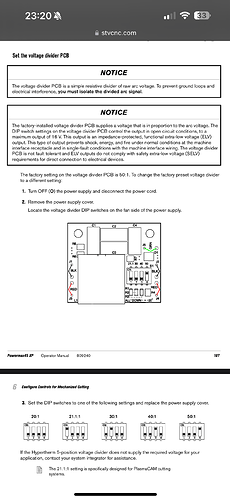

Well it gets better. He just ran the test while cutting to verify the voltage output from the CPC on the hypertherm.

Measured pins 5 and 6 and got 7v while operating the hand torch.

Got 4v while running a straight cut and testing off the barrel connector on the Langmuir supplied CPC cable.

Cutter problem? I tap out at this point. Even though it’s not my issue to solve, Langmuirs instructions may me dizzy.

That one is a doozy. I would only read it if I absolutely had to.

Talk about a descending into a rabbit hole…

Sorry. It will be in the last place you look…or one of those others prophecies

I mean, with the symptoms and following the chart it’s the logical progression of tests.

If I’m missing something, I don’t know what it is. Tests indicate failure in both the cutter and the motion control board.

The filter in the picture was out of my Motor Guard. You see the bulges that is from being compressed in the housing as the filter is a little longer. This is what seals it in the housing. Once removed getting it back in the exact same place to reseal would be rather hard. I wish I would have taken pictures of the ends as you would see the impressions from the housing that would have to line up. And yes, I do not replace my filter every week.

Every one should also invest in one of these inline filters for right at the plasma cutter. These are used in a lot of paint shops right at the paint guns to stop moisture. I think they are made by the same company. I use these on my plasma cutter and air tool lines.

I know the impressions you are talking about now, that makes sense. I found some threads in various places talking about that. It would be nice if the motorguard manual referenced that, but it does not.

Yes I know and if you read some of the Hypertherm manuals it tells you to replace the plasma cutter filter but Hypertherm don’t sell them.

I also get plasma cutters in for repairs with built in filters like this.

Well yeah, but, it’s, you know… ah hell I can’t argue with you. Lol.

I’m a little confused, do I need to replace the motorguard or not? It would atink to go through all of this and run into an issue after the fact because I overlooked this.

In a perfect scenario, apparently you would never reinstall a motorguard filter once removed. It’s compressed and conforms to some dimples in the housing. I don’t think it will kill your performance, but it seems like it might be a good practice. Motorguard recommends checking it daily when starting to use it to determine the change interval, but they don’t say to throw a new one in each time.

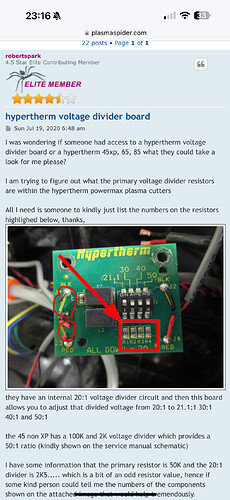

I also found this on the 45xp. It had an internal adjustable voltage divider.

I’m not sure that’s your issue. It supposed to be set at 50:1 from the factory. If it was run on another table in the past someone might have changed it. I can’t remember if you said to night it new. Might not hurt to check.

Before you open that case though, there are capacitors that need to discharge. That is all new territory for me, so proceed with caution.

@Bastrawn with the THC OFF and unplugged how does it cut using Finecuts.

We didn’t try that. Turning the THC off wouldn’t compensate for what the cutter is doing, isn’t it just sensing and changing the height based off the voltage it reads?