I have been through all the fourm info on here and Plasma Spider and not getting anywhere has anybody figured out how to it to work on a Pro table with a Hypertherm machine torch and sheetcam I can’t get it to work it will go to pierce height and then cut height and run the program and never touch the plate.Any ideas Thanks

Someone on here posted some settings that worked. You have to turn the THC off. No lead in or out. Set pierce and cut heights to 001". It had to be a non zero cut and pierce heights for IHS to work

Yep I have done IHS but still same issue it does what it should but doesn’t put more down pressure or push the tip down harder to the plate it will scribe a little but only because of the waviness of the sheet.

Plenty of videos showing how to do it easily.

I even found a walk-through on how to perform hatch fills easily.

I’d offer a how-to but I don’t use Sheetcam and never have but it’s pretty easy on Fusion as well.

I just set a negative value for cut height and done. Just make sure you turn off THC.

Thanks, but i have set a negative cut height in F360 and still get the same result does the same thing in F360 or sheetcam I’m begining to think it has somrthing to do with the IHS .By the way that looks great thats what I’m trying to get.

What result exactly? Can you post a picture?

Look at that users other posts as well. He’s used an easy scriber extensively with sheetcam.

Very light etching and hit or miss I will put a picture on tomorrow I’m not at the shop now… Thanks

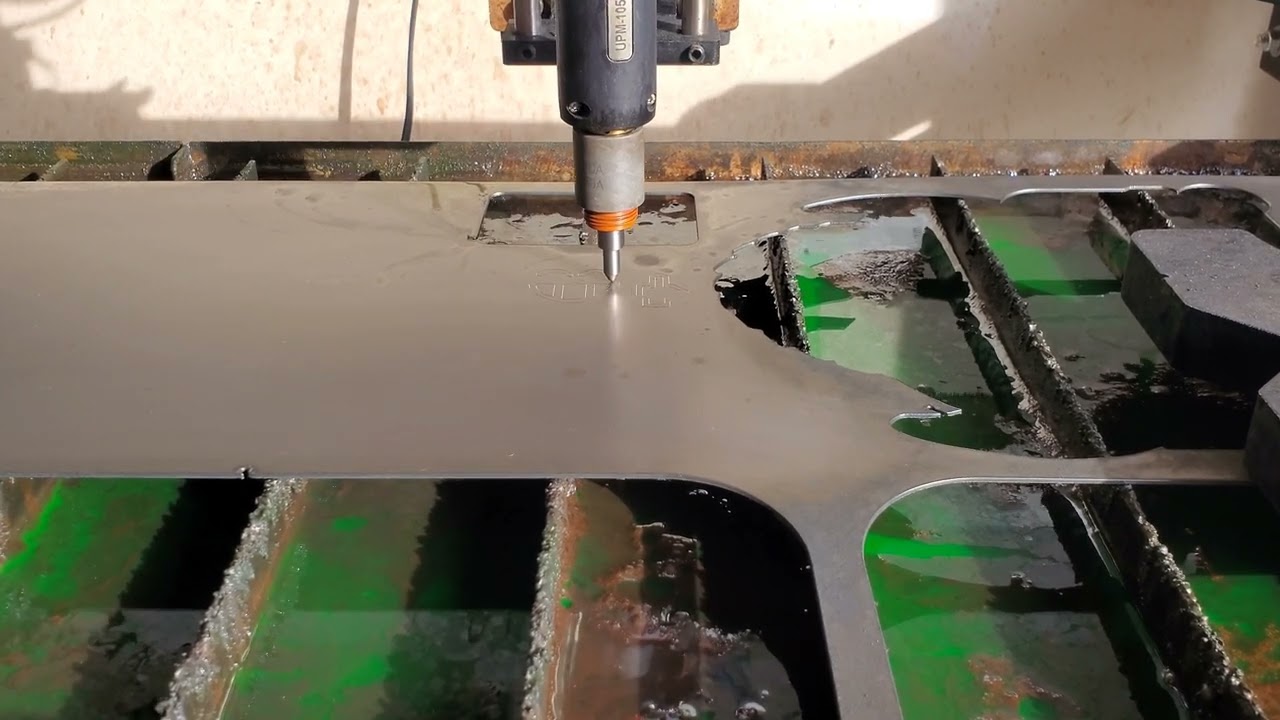

The above piece was 16 gauge mild steel, with 1 pass at 100ipm and a cut height of -0.2".

I know some people do more than one pass as the etching is very light in general.

Well it’s working now I think maybe it didn’t like the -.100 in the tool setup it’s set at -.300 now and this is how it looks…but it doesn’t have as much Z axis travel as in the above video.

Next problem where do I find and setup hatch I’m 72 and sometimes I need a little step by step help lol

Pretty sure you need to add the hatch lines in your design file. I don’t think sheetcam has any hatch fill settings.

Depending on what youre designing with it could be very easy.

If I were doing it in my program affinity, I’d lay out the hatch design larger than the graphic, then copy and paste it within the graphic itself so I didn’t have to terminate each line at the outer perimeter of the graphic.

@KDPMotorsports This is from a older topic with links to videos about hatch lines.

Hello all

Just wondering if using the scriber will cause any premature wear on the motors or any other parts? I understand it is a light drag but it is still dragging along the metal.

I don’t know. I ordered one last week and have it in the mail. I’ve been meaning to get one for years.

The extra drag on the machine is the one concerned I had as well.

Well knowing you from the forum I am sure you will work the crap out of it. Its on my list of purchases. please keep us updated once you get going.

This member looked like they had it figured out years ago.

@ArcForce How is the EZ Scriber treating you these days?

From having watched my own setup run, the drag is minimal as the small spring is barely compressed within the easyscriber itself.

You’d probably run a greater risk for ‘drag’ with gunk on your lead screws building up on those plastic couplers.

I’ve used a scriber on my CNC router quite a bit. I don’t use one on the Crossfire system, but my sense is that your Torch cable will be a greater drag than a scriber tip would be.

Hey Tin,

Thanks for the “shout-out” about the Easysrciber.

I use Inkscape and Sheetcam.

For me, it was more about trying to figure if this was something that could be useful or more of a gimmick. I found that it works amazingly well for the AL and put in nice deep grooves that would not blend out when finishing. There will be raised edges from the movement of the material, so going over the metal with a polisher will make it smooth again.

You would have to go over MS multiple times, like others have said, and that works for small pieces. The only way around it is to paint the surface first for the contrast to show.

Just make sure that the piece is secure in some way so it doesn’t move when scribing, that’s the biggest worry. I didn’t notice any drag of torch, honestly, the spring pressure is so low, I doubt it really needs any consideration. I tried lowering from -.100 to -.300 and there was no difference in groove depth. I thought about replacing the spring for MS to get a deeper groove but changed my mind because I thought it might affect machine.

For me, no real practical purpose, more of a “wow” factor for people to say “That’s cool”

How about hatch fill what do you use if at all.