Recent project.

Traced in Inkscape with hatchfill

Processed with sheetcam

8 inches tall, .080 AL

1/2 hour to scribe, elapsed/ total time WAY longer

Hypertherm 45xp with machine torch.

Nice job! The scriber attaches directly to the torch? What were your Z and ‘cut speed’ rates?

You have to gut the torch.

The only thing holding the Easyscriber in is the retaining cap.

Nothing else needed.

I have posted screenshots of my setup here

https://forum.langmuirsystems.com/t/easyscriber-sheetcam-settings/23889

General Info.

-

THC is turned off

-

Negative number in the Cut height (-0.1" works best) for AL

I have tried -0.1 and -0.15 on HR steel p&o and it only scratches the surface.

It is spring loaded and no difference in depth so you only have to get past the IHS for it to work. -

Make sure to choose shortest path in Cut path when setting up Operations in Sheetcam

Hope this helps

Would like to see what others can come up with.

Oh Jeez ArcForce. As if I didn’t have enough toys! That looks amazing! ( Think I’ll have to give myself a present.)

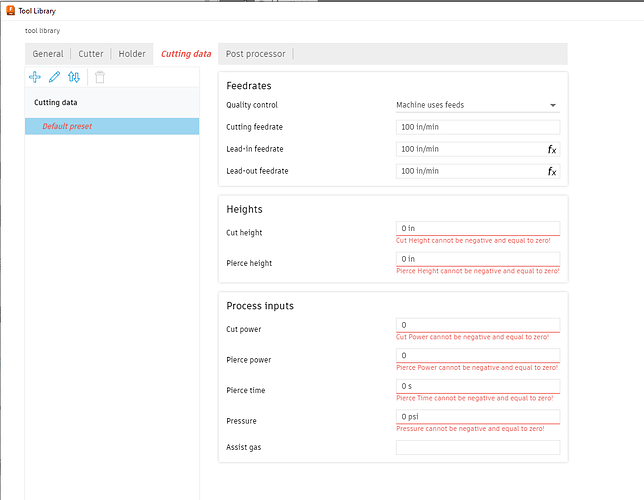

It looks like you can no longer use negative values for cut height when setting up a plasma tool for scribing in F360. Anybody found a way around these new params i’ve never seen before.

I don’t believe to new value inform the post processor.

I filled them out honestly and was still able to set whichever values I wanted into the NC program menu as normal.

Existing tools will still work without adding this information.