this is a great level of cooperation and what this forum is all about…helping each other…sharing information and even parts…makes me what to start a camp fire and sing songs…

Exactly!!! A great bunch we’ve got here!!

I offered to let folks borrow mine on a pass it to the next guy model last year but got no takers. Mine was a standard dimple die with a solid core though so it required 3 whacks with a 4lb hammer to set the dimple. I got it off Amazon.

Wasn’t a cool one like this where it could be drawn tight via a center rod/bolt.

Chris!! It’s on the way!!!

Great work, u should add in with the die a diary, so whoever uses it writer there name and location on it and then send it back to the guy who made the dies when done, even though this thing will probably never stop.

Also add me to the list too plz. Australia

IAttached are updated drawings and Fusion 360 file. I modified the punch and die to eliminate the problem Bill P. had. In the old design if you cranked down on the bolt the dimple made the hole large enough that the drain practically fell through plus the dimple was conical. The new design should cause a depression around the existing hole to a depth of 1/8” but leave the metal around the hole flat so the drain lip sits flat. As of now that is theory…I need to turn one and try it but wanted to give folks a heads up. Ill make one and do another video. (Remember to change the name of the *.DXF to remove the .DXF extension)

Drain Dimple Die (Mod2) Drawing - Die v1.pdf (139.1 KB) Drain Dimple Die (Mod2) Drawing - Punch v1.pdf (133.3 KB) Drain Dimple Die (Mod2) .f3d.DXF (88.2 KB)

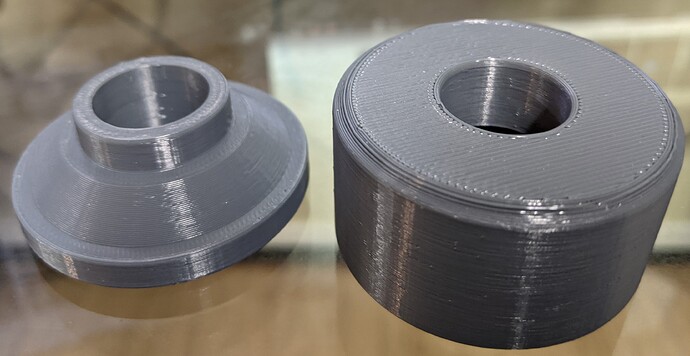

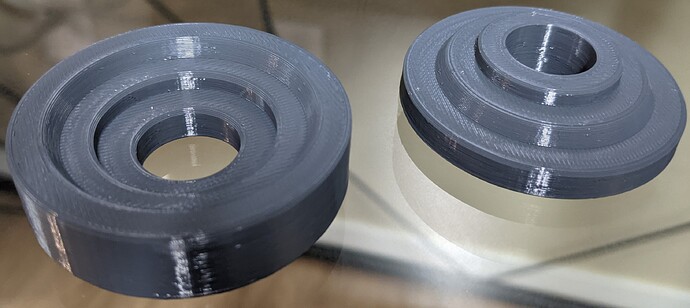

Thanks so much for the dxf. I’m going to 3d print it then try and do it on my lathe too!

The file is a fusion 360 file…the DXF extension was added because this forum won’t allow .f3d files to be posted so you have to “trick” by adding the .DXF. If you really want a DXF file for 3-d printing let me know because I think Fusion can output a .DXF

Another thing you can do is ZIP up the file. The forum now allows ZIP files.

Yup thanks. I figured it out. I use Fusion360 as well no problems getting it to gcode! Really I can’t thank you enough. As someone who has zero experience on the lathe it’s a huge help to have a physical model to reference.

I’ve turned the new die set and redid the video but it needs a bit of editing. Hope to get it posted soon.

That’s what I so enjoy about this forum. Bright ideas and very kind and thoughtful people! Keep up the GREAT work! ![]()

Way cool! that looks like the original design…have you looked at Mod 2? Mod 2 reduces the flare height and leaves a flat for the sealing washer…better design in my opinion

Oh nope. I’ll check out v2 and print that too!

What 3d-printer do you have? I’ve been shopping around. Don’t want to hijack the thread, but curious…

Very cool…are you going to try and “dimple” something to see if it will work? Even if only good for a couple of holes you might be able to sell these to folks wanting to mod their drain.

yeah I’m going to give it a go and see what happens. It may not even make one dimple, but you never know until you try. I still need to print it at 100%, but I wanted the first one to go quick just so I could get sizing and maybe start looking around for where I can find some 2" stock to try and turn it on.