Been all though this previously with more knowable people on the forum , and Langmuir’s support and I still can’t get this damn thing to fire when the THC is turned on. and when I turn THC off It will not cut the first part of the piece, but it will cut the second half.

Check list :

raw voltage test 192v , 3volts out of the vim to the box

Cut height .060 Pierce height .110 Pierce delay 0.9

Ground clamp to the plate. No continuity between the box and table, lap top unplugged.

Reseated the module and relay, check voltages in the wires and board , poked and wiggled all the connections. Air and consumables good.

Got a new lap top and running windows 11 and the latest updates. Program runs a lot smoother and faster. But still same old problems NO FIRE except for manual torch fire. I can strip plate all day long but can’t run a cut file.

Turn on the THC and hit start, live voltage square on the screen reads 2-3volts for the moment the torch fires then goes dead. Windows pops up torch move before voltage was …

And your machine is set up for Dry contact mode ?

On the vim we are connected PV output to the electronics enclosure?

And you’re using the right post processor? Not the TD ( thermal dynamics variant)

Can you post the NC file that’s failing.

I am plugged into the PV port. and I am getting about 3 volt signal when I dry fire the torch.

Post processer? just the one in Fusion.

Thermal dynamics variant??

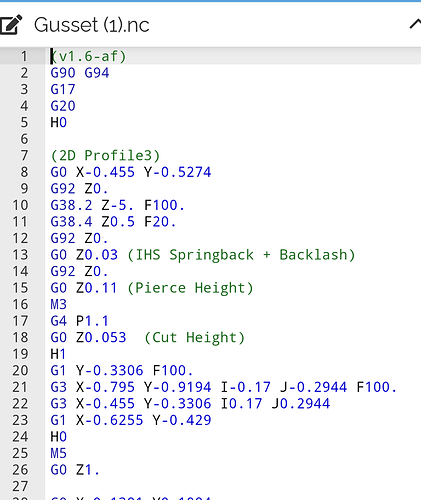

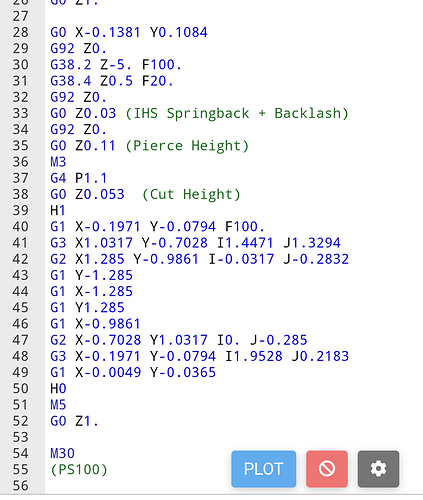

NC file is the same one I have been using with limited success,

Other than adjusting the pierce and cut height ,pierce delay are the same

Do you have another plasma torch you can try?

Can you post your NC file?

You said historically you’ve passed your THC test?

Have you tried running a program without any torch height control?

How far did you work through the THC troubleshooting flowchart?

yes I have with limited success It will run the table fine but the torch misfires on the first torch pierce. then on the second pierce it fires and cuts the rest of the piece.

I think the box is wacky.

Can you post your NC file so I can see if you’re using the correct post processor.

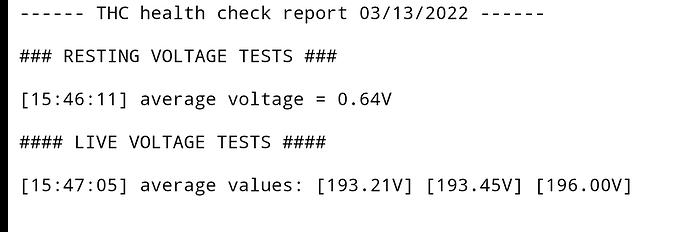

THC-Test Report_03-13-2022_15-47.txt (215 Bytes)

Gusset.nc (841 Bytes)

Send me a little file of something I can run to see if its my programing that’s the problem.

Yes the back lash is high. That’s why I reduced the pierce and cut height and the torch is still running high, the pilot arc still touches the plate though.

I was looking around on the forum site, I’ve posted some test code a few times but I just can’t seem to find it and I’m not in front of my computer currently.

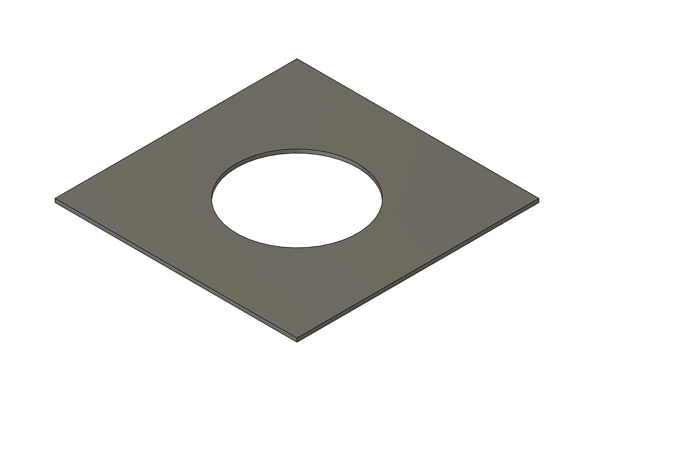

Anyone else out there have a square with a circle in a piece of test code they can post?

test square.nc (991 Bytes)

try this simple test square

2"x2" 1" hole at 100ipm .06 cut height .15 pierce height .6sec pierce delay

use smart voltage by setting the thc voltage to 0 volts

I am still suspect of the dry contact vs xfer connects ( jumper ) in the machine. These need to be in the dry contact position.

Page 53 of the manual can you take a picture of this location.

Clamp on material for sure!

Simple test square / still will not fire

Put in the jumper for xfer connect. fired and cut one piece. ![]() next one misfired, same crap

next one misfired, same crap ![]()

reset misfire again This happened two more times with letting the machine time to full reset (air blow down)

Now reset misfire/ reset misfire/ reset misfire/reset fire run program??? all from the pierce start position as fast as I could reset and hit start not giving the cutter time to reset (blow down)

Move to the next cut same thing.

This is baffling. I have got more action with the jumper installed that’s good.

New THC test results

THC-Test Report_03-14-2022_12-54.txt (215 Bytes)

Could you screenshot your fire control as it would be before you start cutting.

Also maybe a picture of where you’re making these connections inside your hypertherm and that jumper wire area.

I would really like to see you try another plasma cutter on that setup if possible. I feel like the okay to move function built into the hypertherm maybe causing some issues.

If you had a another plasma to try we could at least know if it’s your hypertherm or the langmuir definitively.

I may have found the problem in the cutter its self. I am in process of running tests per the service manual. Seems I have a voltage discrepancy between C94 and C98 capacitors. It may warrant a resistor replacement. I need somebody to fire the torch wile I check voltages.

My friend has a new powermax 65 that I am going to borrow as soon as I get a hour to go get it.

Just got off the phone with Hypertherm tech They don’t feel there is anything wrong with the cutter. and to look into the THC control,

Once you try your friends 65 you’ll know right away if that’s the case.

So true, but if that doesn’t work then what? I am going to get this afternoon.

Are you going to hook up the 65 for raw voltage or divided voltage(if it has a CPC port)?

Sorry we were both mislead  It is a new machine but it is only a XP30 and no CPC port And I am not about to open up somebody’s new machine that’s not mine to wire up on this table. I’ll have to find another one somewhere else.

It is a new machine but it is only a XP30 and no CPC port And I am not about to open up somebody’s new machine that’s not mine to wire up on this table. I’ll have to find another one somewhere else.

I wish I was near you I would drive over and help.

What area are you in ? maybe there’s a a member around that could come by.

I’m on the tip of the Idaho panhandle