Thanks for the offer but I am clear over in Western Pennsylvania in Notown no jobs/ no opportunity’s /no future /no life.

Reading through this. Didn’t catch the answer

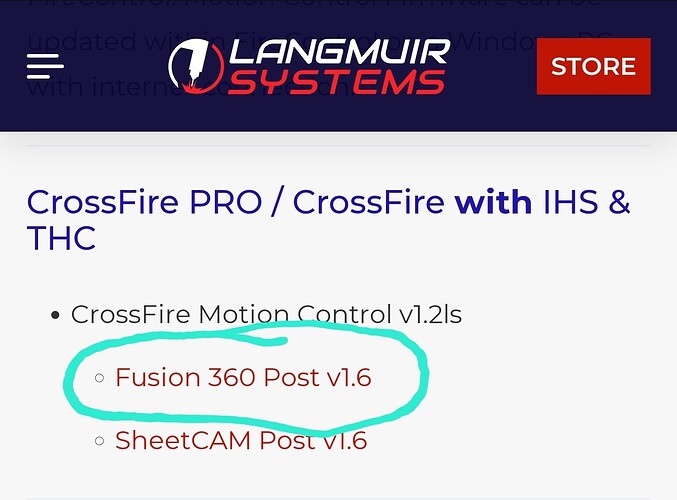

Post processer? just the one in Fusion.

Thermal dynamics variant??

Did you say you did download from Langmuir’s website their post processor for Fusion or no? There are two. One is with Z-Axis Upgrade and one without.

Z axis up grade

Yep the same.

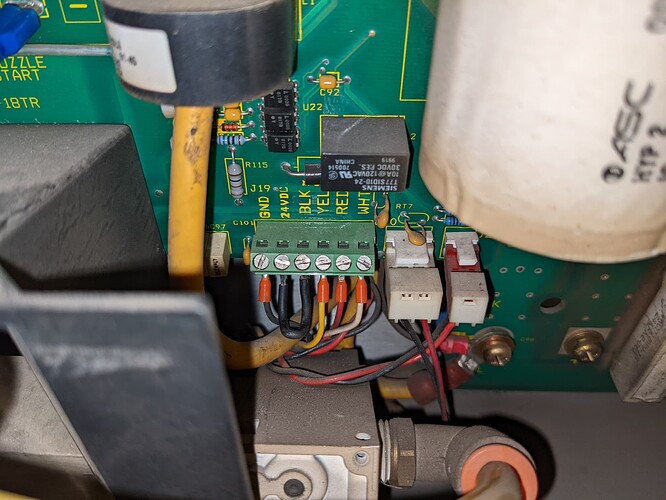

I have made a few cut files. and TinWhisperer send his own cut file for me to try. @support feels that its a weak torch relay and are sending me a new one.

Yay, hope that works out for you.

Hello,

It sounds like your experiencing the same problem I’ve been having with my Crossfire XL with THC upgrade. Almost word for word.

I too have been back and forth with Langmuir tech support via email until I finally complained about the piece meal suggestions on what to troubleshoot as it just wasn’t detailed enough to troubleshoot as the faults occur.

Aksel Langmuir finally took over the communications on their end and provided me with troubleshooting suggestions in greater detail so I could check a lot of what might be the cause of the problem as it occurred.

I just finished my troubleshooting for this issue and will be forwarding all of my data to him tomorrow for his review. I will provide the response as soon as I receive it. That being said here’s what I did so far:

Loaded a small test file into FireControl.

Toggled THC off.

Ran file three or four times until torch misfired. Attempted additional cuts and torch continued to misfire. At this point since THC was off and not monitoring live voltage the misfires pointed to the cutter. I’m using a Thermal Dynamics CM 40 ( brand new). I removed the torch from the machine and performed numerous manual cuts on scrap metal with no problems. Misfires are sometimes caused by the torch tip not separating from the other part (can’t think of the name right now) in the torch. When you fire the torch the air will separate these parts and you’ll get your pilot arc and then cutting arc as soon as it transfers to the material. However if the tip is too close to the material when it fires the material will block the air coming from the tip, parts will not separate and you will not get the pilot arc (misfire).

This happens even after IHS because the metal will bow/flex as it heats up so at some point during the cut program the tip can end up to close to the material. My solution was to adjust my air pressure a little higher than where I had it to allow for more force to separate the torch parts.

I first went lower on the psi and that most definitely created constant misfires. After I adjusted up an additional 5 psi from my original setting the misfires subsided UNLESS the metal was to warped. Remember this is without THC enabled. This is where clamping the material down is essential.

Next I turned THC back on.

Loaded a larger more complex file.

Ran fine three consecutive times. On the fourth run FireControl detected loss of arc and paused the machine. This is now a different problem that I’ve been having. It sometimes allows me to retry the cut’s from that point forward and the job will complete. Other times it will not sense the lost arc and continue without firing the torch. At some point later in the program the torch will fire again and the job will complete except it will have some cut lines that didn’t cut when the torch didn’t fire. The misfires when THC is on I believe occur because as the torch moves down on IHS the tip will bow down the material and cause and erroneous material height reading. So when the torch retracts to pierce height the metal will flex back up and your pierce height is now too close to the material and upon torch trigger the torch parts don’t separate and hence no pilot arc (misfire).

FireControl should detect the misfire when THC is enabled but it doesn’t always do it so that is a big problem.

So now I checked the raw voltage from the cutter, the voltage coming from the VIM box, and the voltage at the THC chip while performing straight cuts. Everything checked out. Voltages were what was expected. I ran a few more straight cuts and then at the beginning of the last cut the torch fired and FireControl detected a live voltage of 295 to 300 volts while the voltage at the THC input on the control box read approximately 1.9 volts which corresponds to approximately 140 volts raw.

This to me suggests a problem with either the THC board or the motion control board. So I’m hoping that Langmuir will concur with my results and send me the parts I need as I just bought the machine last December and have only been using it since January.

Yeah it’s a long reply to your post but given the frustration that you’ve been going through maybe it’ll help get you going.

And like I said as soon as I get a response from Aksel at Langmuir on this issue I’ll post their response. Good luck! Whew!

I don’t want to be a downer here. It sounds like you may have a more complex problem than I have. My machine is working as it should except for when the THC is on, It can’t sense the voltage ( that has been verified that is there) and shuts the program down.

As far as the piece meal suggestions goes, everyone is trying to help the other and we all have different levels of experience with these machines. Since I started I haven’t cut more than a dozen or so test pieces correctly. but have had probably 400 to 500 misfires since I put the machine together 3 weeks ago But with the help of the forum and Langmuir support we work though it from the ground up. One thing for sure you give these guy all the information as in ,which machine air supply dry and filtered, ground clamping, material and thickness. Everything even if you think it means nothing, It means something to somebody. These guy will figure something out.

I to will be posting my results when we get this thing up and running. I’ve been spitting nails for two weeks now over this set back. We have a solution coming, I just have to wait on the mail

stop with nails…start shitting sheets…you can at least use them later…hehehehehe

we all have had a problem or 2…it will work out…

The logistics of this are freighting.

I wish I could shit some sheets I was lookin at the steel prices this morning, This is going to slow a lot of us down to only necessary work. God for bid scraping a piece.

Well finally got my firing issue ( Not solved but a better understanding of it.) First off its not the table. Its not the program or any of the other common issues. I have devised ( lets say a unorthodox way to work around it . But for the most part, the problem is in the plasma cutter itself. I really can’t complain I have had the machine about 15 years and done a lot of work with the hand torch. I been on the phone with the techs at Hypertherm ( about an hour and a half) a they never had a issue like this. and don’t have any answers. They say that my work around is not the way to cut , but it will not hurt the cutter or the torch. Maybe a little harder on consumables and some cuts and pierces may not be as high of quality , so its not recommended. We are up and cutting now with some consistence and that what matters.

A Big Thank You to the people on the forum that expressed their interest and their input to this matter. all of you had great input on this subject ,but no one could have foreseen this malfunction that happens in a nanosecond.

Thanks again, now I got find something to cut.

You have peaked my curiosity. What did you find the problem was and what is the work around you are having to use?

Like I said the Hypertherm Tech never seen anything like it. He feels something is weak or out of frequency range for arc transfer. All the tests and diagnostics we tried came back good and in range, no error codes or flashing lights nothing. The work around is the only way it will pierce cut. and that is not the way the pierce cut operation is to work. Lets just say I feel it is dangerous and I would not recommend it. Others may feel differently about this, But I will sleep better if I keep it to myself knowing that my work around did not hurt anything or anyone because I am no expert in this field.

Fair enough