Link to the previous thread that was in the introductions section.

Took delivery of my new Pro w/Cut45 today in Central Oregon

I thought I had this problem figured. I drove my brand new Razorweld Cut45 to Jasic’s warranty repair tech and spoke with him about the problem i was having. He told me it needed a motherboard and he usually has some in stock but was out, however he had 5 on order that would be here in 3-4 days. Cool, left the machine with him, drove home. Today, 5 days later he calls and tells me I can come pick up the plasma and that there is nothing wrong with it.

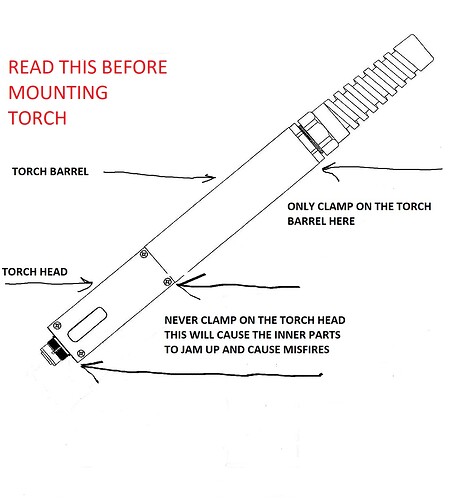

He installed his hand test torch and it fired right off, he put my machine torch lead back on it and used it to cut a piece of 1/2" plate without a hitch. He also said there was a small air leak inside that he fixed and that the air pressure setting on the machines internal regulator was set to low, he adjusted it up 12-15 psi to have 75-80 psi cut air with the torch cutting. I laughed because I knew exactly what was fixing to happen. I drove back to pick up the plasma and talked with him again, a nice older fellow I didn’t want to ruffle up but I explained again it would not fire with me jumping the connection on the front of the plasma, multiple times. He offered to unbox the machine and go show me, I said it wasn’t necessary if he was that confident. We went over the wiring to the control box and what i had connected where and that the front connections on the plasma were wired correctly. This is the way. So, off I went. Back at the shop, 220V measured at the receptacle, 90 psi air pressure at the rear plasma, shows 90 psi on the front gauge, pull the wiring apart to be positive the correct wires are connected to the right ports in the front of the plasma. Inner port closest to the torch lead connected to on/off port in control box, outside port 50:1 wire connected to DIV input, DIV output connected to THC on control box, ground to work piece, did not touch the torch head and installed it as lightly as i could on the Z axis only clamping on the metal part of the handle, run Z axis and torch down to touch the table then off table 1/8" using the jog, THC shows green and connected, IHC is setup, home the table, run out to work piece, zero axis, torch still 1/8" off work piece, enable manual torch fire and click fire torch, I hear the relay click, air starts coming out the torch tip and drum roll please…the torch doesn’t fire, again, for the 100th time. Run the torch closer and higher, no fire.

Next step, open the THC troubleshooting guide, step 1 connected with Langmuir cable, yes, step 2 Have you verifed that your

plasma cuter is wired up

correctly for THC by performing

the test checks outlined in the

THC VOLTAGE CHECK GUIDE

below?

Scroll down to voltage check guide at bottom of page.

The very first thing it says is:

1.) Verify that your plasma cutter’s 50:1 voltage divider port is functioning properly while cutting.

If your plasma cutter is equipped with a 50:1 voltage divider in the CNC port (called a CPC port on

Hypertherm), we will use your Digital Multimeter (DMM) to measure the DC Voltage across the two pins of this port WHILE THE PLASMA IS CUTTING.

![]()

Some more history if you don’t want to read the post linked at the begging.

I have a Hypertherm Powermax 30 that i wired into the control box on/off port that works fine with the table. I downloaded 4 or 5 programs from Fireshare and cut them with the Hypertherm connected to the table. IHC worked, I did not have THC enabled to do this.

Tuesday will be 2 weeks trying to get this #$%^ machine to fire. The excitement has ran dry. Langmuir support says it’s the torch, the torch warranty guy says Langmuir always blames the torch and most the time the problem is in their wiring connectors. He also expressed to me that they have a new digital cut45 plasma that Arclight Dynamics is now using in place of the Hypertherm on their units. He also let me know that Arclight is going to be releasing a new plasma table with the digital Cut45 plasma to directly compete against the Langmuir Crossfire Pro in the next month give or take.

![]()

Jumping the leads in the front of the plasma won’t fire the torch, I don’t have a hand torch for it to try and see if that works, Hypertherm hooks up and works still. I don’t know what else to do but take it apart and return it then buy an Arclight.

You guys are my customer support i guess so anyone have any ideas what to do now?