Good evening Ladies and Gents. I just finished unboxing my new Crossfire Pro with Razorweld cut45 this evening here in Redmond, Oregon. Excited to up my game with it building custom parts for RestoMods and general hot rod building. Only hang up I have is after unboxing it I realized I still have not purchased a PC system to operate it yet so I spent the last hour scrolling through pages reading about different setups to run this unit. I’m surprised that Langmuir doesn’t have a recommendation page with some options of different setups to run this thing. From what I’ve seen so far something with a touchscreen is a must for many people. 16 gigs as a minimum, gaming style setup people say is good. I originally figured on using a laptop on the stand that attaches to the unit but after reading some posts I’m not sure i want a 2k laptop sitting that close to it now. I was at a guys place the other day and he had a 4x8 ARClight table he was showing me and his table made very little fumes and almost no splash except on the table while cutting some 1/4 plate pieces for me. Is the there really that much debris that come off one of these tables. I was going to put mine in my metal working room which is already packed with stuff but i’m wondering how much room a person needs around the table. Is it better to have a small desk next to the machine to put the PC on so your comfortable while building the files and running the software. I was going to get a laptop that can run all the programming software and control software but wonder if a desktop with a larger stand alone touchscreen might work better. Anyone care to share their experience with the setup they use. I want my setup to be as simple and functional as it can be. I don’t want to design on one pc then have to email or take a usb drive to another to run it. I have employees that will use it and knowing how they are with tools makes me think they would loose the usb between the office and metal room.

@Covert1 welcome to the forum and congrats on your new purchase!

Click the link below and scroll to the bottom and you will find the system requirements to run Fire Control. You will also need to verify the system meets the requirements for whatever CAD/CAM software you intend to use.

https://www.langmuirsystems.com/firecontrol

My laptop has a touch screen but I never use it when operating fire control… I dont think touching the monitor is a great idea with grimy/wet hands.

I also never use it when drawings in fusion, a CAD mouse would be nice but I dont have one of those either.

This is more than you would need, but if it’s in the budget then great.

I think this is the one I am using… I will double check…

I have mine setup on a work bench near the table where I can sit and run the table and make changes to the design as necessary. I also setup a shield to protect from any splashing ect. You are limited by the length of the cable. I have seen some use a rolling toolbox from HF or HD and it seems like a good way to go.

As far as splashing goes if you are cutting around the edges of the table you will get some splashing… especially if you end your cut near the edge of the water table. Make sure you have your jog in fire control set to continuous and have a plan where to move the torch to wait out the post flow.

I bought a small laptop that already had Windows 11 on it from Costco for $700 to run the table in Nov. 2021. At that time, FireControl was not fully dovetailed into running on Windows 11. Within a month, a new update from Langmuir had it running fine. This computer has a 14 inch screen, too small for designing. It is not touchscreen and I use an external mouse. It works fine. It has the capability of running Fusion 360 but the small screen makes it NO JOY for design work.

I have mine set up on a folding table about 10 feet from the table. Yes, that means I have an extended 16 foot cable from computer to the table (not recommended by Langmuir but many have this type of longer cable). My suggestion is to set your table up with the short cable that Langmuir supplies. Get through the initial “dialing in” your machine and once everything is working as expected, you can make small changes one at a time and see how that changes things.

You mention gaming capability. Yes. For your designing computer, you want a very capable machine and if using Fusion 360, a good connection to the internet. The computer running the table is not needing all that power. I think where the confusion happens is that if you are able to have two separate computers, you don’t need a powerful computer at the table. If you are only going to have ONE computer, it needs to be a very capable machine for designing.

And, I agree with Erik: Once you start cutting, your hands are going to be getting pretty grimy with water and such so touching the screen does not work with my style of treating a computer.

Another note: Some have remote setup with a computer that operates the table. That is beyond my computer skills!

I’m using a Mac Mini and old 1080p TV/Monitor to control my Crossfire and the CNC mill.

Welcome to the forum!

Not to be silly, one thing to consider is your waist size. I am thin and I feel 24" minimum around the X and Y distant (from PC stand) sides is required. On the Y minus side I think you need to consider the size of sheets you may want to feed onto the table. I have laid 8 foot sheets with a roller stand. On the computer/controller side, that just depends on how much seating and PC space you want.

You’ll have water splash on the floor and metal dust in the air unless you have a really good air handling system. I use the “open door method” right now and there is still a metal dust accumulation. I wear a respirator during and for 10-15 minutes after depending on air currents. I also use a leaf blower to blow dust out the door every week.

@72Pony, @ChelanJim, Thank you very much for the detailed response’s to my questions. I’ll add some more flavor to my situation. Your answers certainly are helpful. your response will move my pro into another area of the shop. I’m 6’2", 195, 34" waist so if you need 24" I will also. The room i was going to put it in would be tight and loading work with other equipment around it may be an issue. I’m also planning on only using this for about a year and then ordering the XR which will not fit in the room at all. There is good ventilation and extraction in the metal room but now i think I’ll install a separate exhaust for the pro in another corner of the shop.

I’ll let the cat out of the bag, I know nothing about the software or what CAD program I should run. Didn’t even know i had options for it. I thought the system came with it’s own drawing program and control software. My area of expertise with computers is engine and transmission tuning with a laptop and my experience with using a computer for other stuff besides cruising the net and research is zero. I remember in high school my shop teacher telling me I should really learn to use CAD and take his class but I didn’t think it was something i would ever use. There have been many times in the last 20 yrs i wish i would have listened to him. I have a new Cornwell tool cart that is just holding some of my wiring tools that I’m going to repurpose just for the CNC table. I think I’ll not use the laptop attachment I got with it and use the cart which has USB ports and charge ports in it with a laptop shelf to setup on. I can close the lid when not in use and when the lid is open it will act as a splash guard between the table and PC. So now I just need to decide on my setup. I didn’t budget 2k for a pc when i ordered the table but I think I would prefer to buy 1 good laptop even if it takes a few payments to get it. I have 2 new desktops in the last year, a new Acer Nitro 5 gaming laptop i use for tuning, a new Microsoft surface and a new Lenovo thinkpad that lasted 1 week past warranty. All bought from recommendations from the Geek squad at Best Buy. The only one that works worth a dam is the Nitro 5 so I’m on board to spend the money for something that will get any job i throw at it done and done quickly. I’m considering at the moment using the ASUS ROG 16", I9 core, 16GB, 1TB SSD, RTX4060 graphics or the MSI Creator 17", I7 core, 32GB, RTX 3070, 1 TB and then putting a 27" or 32" HD monitor on the wall behind it. I don’t want to buy anything else once it’s together and running. Plus i don’t retain knowledge as well as i used too so learning it one time one and using hopefully a pc that will last until I forget how to use it will pay off in the long run. How long is the learning curve for the software and getting the machine dialed in? I don’t suppose any of you happen to have no experience whatsoever when you bought your tables? LOL…

@Wsidr1, @mg6studios couldn’t mention you in the last post. Newbie and all that.

Most people use either Inkscape of Fusion 360 for CAD. There are other free programs for CAD.

If you use F360, it does both CAD and CAM (generating G-Code to run table). If you use Inkscape, most people purchase SheetCAM to generate their G-Code. Sounds like the software might be your challenge. No way to guess how long that will take, but there are a lot of free FireShare files you can download and cut.

As for “getting the machine dialed in”, most of us on here will tell you we are always learning/tweaking continuously. However, I started with no CAM experience and only hobby level time investment and was cutting really pretty well in 3 months. This forum helps tremendously. There are many people here willing and able to help.

When you start posting questions, just use the search feature first, then if nothing found, give as much detail as possible on your setup & problem. There are a lot of Razorweld 45 users on here. Follow through on the advice and you’ll get up and running quickly. Probably quicker than I did because I am stubborn about asking for advice.

Ram and graphic cards are two of the biggest part of running smooth in CAD programs. I use Fusion 360 for everything. I have my own fabrication and welding business and I use the fusion to model everything. The biggest surprise for me was when I model big stair projects or other things I have very few problems. However when I do 2d art stuff for the plasmas table it starts to show my lower powered graphics card and low ram. The art stuff has so many splines and arcs it causes the computer to really work to compute it all. I had an older MacBook that couldn’t even load what one would think was a simple elk and mountain scene.

@Covert1 - Welcome to the forum.

I’m newish around here too, great bunch of people here for support and encouragement.

A little tip for you, paragraphs are your friend. Your posts are a little hard for some of us to read.

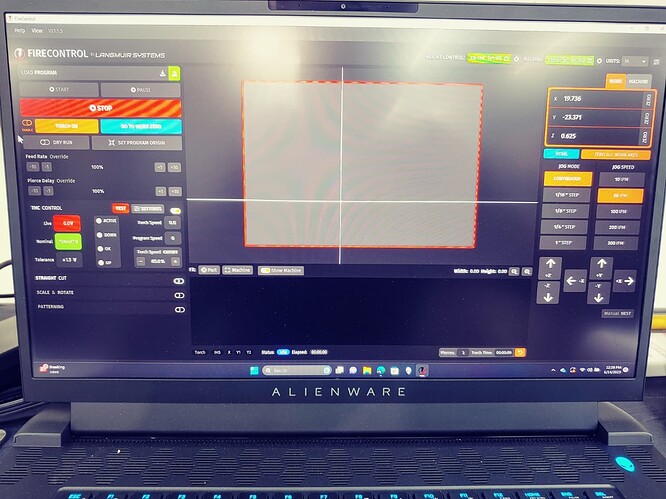

@Sticks I was just about asleep when i wrote that responce. Not that my grammer is that great anyways. As for the table, I spent all weekend getting it built and setup, got it connected and hooked to the fire control and used the manual jog features to make sure everything move and sounded ok, then my laptop i was trying to use took a crap. So after some more consideration I ended up going with this setup.

Ordered 5 gal of Sterlingcool Plasmacut for water table.

Purchased Alienware - m17 R5 17.3" 360Hz FHD Gaming Laptop - AMD Ryzen 9 - 16GB Memory - NVIDIA GeForce RTX 3070 Ti - 1TB SSD - 8 Core - 4.9GHZ

Built a double water trap in my airline with auto drain and put a motorguard M-60 filter assembly on it.

I was doing some reading about grounding the plasma. Saw several options, to the workpiece, edge of table, to the slats, to the tavle drain. I can see where grounding to anything but the workpiece could be a problem with all the pieces being loose in the table. What I was wondering was, is there any reason why someone couldn’t weld a tab on the bottom of the work table and tack weld the slat holders to the tabe and run it that way. I wouldn’t think there would be a problem with loosing the ground connection that way and can’t think of any reason I would need to pull the slat holders out again. Ever hear of that being done and if it worked?

Whoah! When there is talk of “grounding the table” people are talking about actually “grounding” to an earth ground.

They are not talking about the “work clamp” from the plasma table. Many of us have had success and less than successful connections from the slats to the work piece both by accident and on purpose. The general consensus is that you really want the work clamp from the plasma cutter attaching directly to the metal. Your idea of the tab makes sense if it was agreed that you would get superb connection through the slats to the metal. You are not always going to have pristine slats and clean metal.

Work as hard as you can to always try to clamp to the workpiece. This will eliminate some headaches and give you the best cutting situation.

Looks like a rock solid computer choice. You will love Sterling Cool. It is great stuff.

I gotta agree with Jim on this idea. My slats look like they are encrusted with barnacles after only moderate cutting for 6 months. They still work fine for metal support, but I have to think that the work clamp is getting much better continuity being attached directly to the work piece.

I’m just using a welding magnet with a flat piece of 18 gauge welded to it. Low profile, easy to position. Works very well.

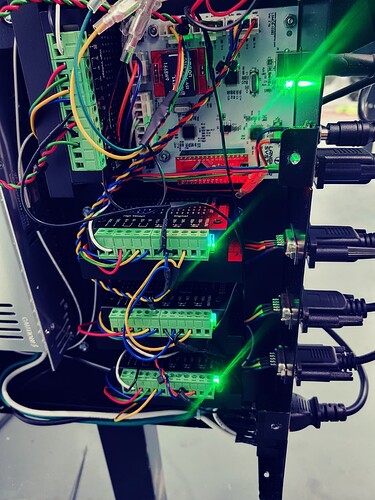

@ChelanJim @Wsidr1 I think a welding magnet will work fine for me. So I have the table setup, leveled, everything hooked up but I can’t get the THC to work or the plasma to fire at all. Even manually. I switched the connections on the front of the Razor weld thinking they were backwards but that did nothing, I ohm checked the cords end to end, took the cover back off and looked at the LED’s and I think the right one’s are lite up. I ran the break in program, got the limit switches and soft stops all set, homed the machine but still can not dry fire the torch. I looked at the settings in the THC but didn’t change anything. Everything on the fire control appears to be on, so what am i missing?

The Red LED is on in the THC module behind the wires. The one that’s lite up is the second from the bottom on the 4 in a row.

Air on and connected? (Would not be the first time…)

Yes, air on, 85 psi.

By manually do you mean in fire control?

Are you using a hand torch or the machine torch? If using the hand torch will the torch fire when you pull the trigger?

@72Pony machine torch.

There doesn’t have to be a program loaded does there?