I’ve seen mention of this as a problem, but why? ( Edit: I didn’t actually have continuity there. I was accidentally touching another part of Z assembly, so continuity between Z and Z—doh!) What sorts of problems should that cause?

I think it’s covered in here.

I believe if you have continuity where you shouldn’t, THC won’t work correctly.

I guess the real question is what problems are you having.

This particular “issue,” if it even is one, is a theory advanced by a couple of users on the forum and members of the FB group. I don’t know enough to even assume that there should not be continuity there. That’s why I asked the question. It is not in the THC guíde, unless it was just added. I have been through those checks so many times I can almost read REF to GND and A1 to GND with my eyes shut.

I have no idea what this ‘issue’ is. I do know that, with a floating Z axis, which I think CF Pro uses, utilizes a switch that opens when the Z is lowered enough to be restricted by the work material after a bit of over travel. The process is very predictable and repeatable if the material is dense enough to be ‘solid’ on contact. Thin material will have a problem because is will warp and not represent a solid mechanical reference point. However, in most cases, this isn’t a huge problem. It will affect pierce quality, but should not affect cut quality if the THC voltage is spec’d properly - this is what determines the torch height during cutting.

Having said this, this mysterious ‘Z axis/IHS Switch Continuity’ makes no sense to me. As far as I know there is no ‘switch continuity’ issue. The switch is on, or off, period.

I’ll go one step further, referencing something that “’I’ve seen mention of this as a problem,” is a very bad practice. You have a reference, post it. We have no room for hearsay in this forum.

I may have improperly assumed he was referencing this troubleshooting step.

I too have no idea the “issue” he’s referencing.

@TomWS on the occasions, I read of this theory, it was not of pressing importance to me. When I went back to look for more information, the only reference I could find was a February 3 comment in the THC issues sticky. Reading it again left me wanting to understand more. (I cannot figure out how to link that post, but it’s there if you care to find it).

If you read my post and comment more carefully, you’ll see that I am asking questions and have not determined there is an “issue” (I used quotation marks in the other comment for a reason). I also acknowledge that I don’t even know enough to say that continuity is abnormal in this instance. That’s a far cry from spreading hearsay.

The purpose of commenting on a post in this type of forum should be to offer help, including answering questions from people who are trying to gain knowledge they don’t already have. Why even comment if all you can manage is to condescend, accuse and try to deem my participation unworthy?

@brownfox quotation marks are used conversationally to suggest doubt. As in this forum is “quote helpful end quote.” Read this from @jone6881

“What I found was that I was getting continuity between the Z axis lead screw and the IHS switch, caused mainly by grit and splashing water. I used a borax solution at the time which probably contributed to the continuity issues. I gave everything a thorough cleaning with isopropyl alcohol, added a funnel splash guard and blow the Z axis out before each run. I have not had an issues in the past month or so. I also added taller Y axis rail plates to raise the Z axis higher above the water table.”

Again, I don’t know if it’s a thing. I have only come here seeking knowledge. Things they did not teach me of in college.

I think you’re the one who should re-read your original post, which I quoted verbatim. It may have not been your intention to generate ‘hearsay’, but that is exactly what you did when you said “I’ve seen mention of this as a problem, but why?” without even explaining what ‘this’ is or providing any reference.

The ‘helpful’ part of my post is in alerting others not to talk about unspecified problems without explanation or reference.

My response stands as is.

@TomWS and @brownfox and anyone else morbid enough to be reading this derailment… Here is a response to my questions from LS customer service. At least one of you participated extensively in the threads in which this was discussed, so it shouldn’t be too exotic.

“When the issues of a dirt between contacts came up, it was explained: Potentially voltage and current are moving into the THC via debris between metal of the Z axis carriage and the IHS contacts.

I attached a screen image with an electrical schematic. Follow the green line from contact to 5V supply. If the plasma cutter puts out 100 V can all that potential be drained away by the work clamp? What if the work clamp did not drain away current fast enough so 7+ volts were left on the metal and table. 7+ would, through the IHS contacts have a means of getting to MCB reference voltage. I am not sure about this but the construct helps explain why it has been observed that dirt by the IHS can cause issues.

Instead of 7+ volts, let’s image 0 volts. Now 5 V at MCB connect moves to IHS contacts on Z axis. The work clamp drains voltage built up on metal, table and gantry being supplied by MCB. The computer can not supply sufficient electrons to keep up with the work clamp draining away via IHS contacts. MCB now supplies only 3.3 volts to THC versus 4.0. Leaving THC making bad decisions about raising the torch. The above is just a theory. You would need to conduct a “scientific” test to prove or disprove the theory.”

woops, didn’t see your other post before this

Well, you say you’ve heard of this, and you have it, but then don’t say what the problem with it you’re having is. I think stuff like that makes people paranoid and search for problems. Is your torch raising? Is your live voltage too low? What is happening?

The other post you’re referencing was about low live voltage right?

I think what @TomWS said is correct though, the IHS is either yes or no, not dependent on voltage.

@brownfox While I appreciate that there are people willing to help, I’ve given up on asking the forum or FB group to help me with complex electronics issues. I have spent way more time troubleshooting electronics than cutting over the past year and I don’t have the time or energy to do more than open another ticket with LS .

What is your complex electronic issue?

My table works great. I do see a pattern of people posting here like they have some unique, undiagnosable problem that prevents them from using their tables like the vast majority of owners do.

@brownfox Jon, I’m truly happy for any owner whose table has met her or his expectations. Good for you.

Lol. I’ll keep playing along.

What is wrong with your table? This feel like a repeat of the guy who basically posted:

“Can’t complete a cut, it’s not my air”.

I ask “what’s your air supply?”

He says “It’s not my air”.

I say “Ok just tell me what your air supply is so we can move on”

He says “Fine, 1.7 HP 27 gallon”

I say “You don’t have enough air.”

Do you want to get your table working, or are you looking for a reason to say it’s not working?

I came on here to get an answer to a question, not to complain. Despite you and your buddy’s mostly successful efforts to derail my thread, I was able to get the information I needed from the source and from LS. Based on what I learned, I have eliminated this theory as a cause of my problems.

would you be so kind as to share what you have learned?

no matter how small or large the issue is we can all still learn something…

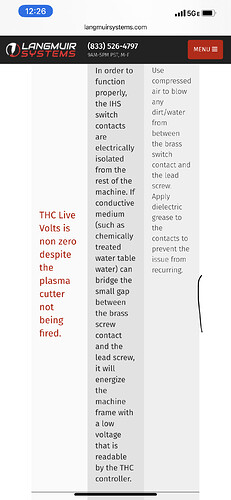

I found this while skimming the directions to answer members question.

Seems like Langmuir already acknowledges this so we can probably take the quotes off the word issue. Seems like anything affecting the live voltage reading would have an adverse effect on height control.

@toolboy In addition to what I quoted above from Thomas at LS, the gentleman whose comments I referenced had this to say:

First off let me start with I did not read the other thread (it seemed to be going off the rails), but I was having an issue with the Live voltage reading when the plasma was not firing (3-7volts seemed to be the most common). The frustrating part was that for me it was sporadic and seemed to only happen near the end of large expensive cuts (Murphy or something). After checking the troubleshooting guides I finally gave Langmuir a call and they suggested that excessive build up of dust and “crud” on the z axis could cause the live voltage to read non-zero caused by continuity between the Z axis lead screw and the IHS contact. After a deep clean the issue went away and has not returned. I did not dig any deeper other than being extremely happy to have my machine back to normal. It has been 5 months or so and with regular cleaning I have not had another issue.

Do you disassemble it every time to clean it?