@Phillipw I forgot to mention, all my cut files are NC.

I don’t think your TAP files will work for actual cutting since I’m on Firecontrol.

@Phillipw I forgot to mention, all my cut files are NC.

I don’t think your TAP files will work for actual cutting since I’m on Firecontrol.

F360 makes nc. Sheetcam does tap.

Wires yes goes to the ihs.

I could be wrong I still see something loose or tight not allowing the proper cut height.

I am at a loss to be honest if it was me I would start looking at everything that moves make sure it doesn’t move too much and if it isn’t supposed to make sure it’s tight.

I would also make sure the z isn’t loosing steps. Best way with a indicator. They are cheap at harbor freight.

Did you watch the video I just posted? Took that today running the first TAP file you provided.

It goes down all the way, a hair up, and a hair down again.

Definitely a head scratcher? You have correct post processor chosen With IHS checked?

Screenshots of post processing shown above.

I have been running my table solid since January without issue.

The only changes that have occured since running 100% good to now are -

Switched to raw voltage

Received a new VIM (using it or the old one makes no difference at all)

Added a connector for raw voltage.

The issue is definitely not voltage related, it’s happening on a dry file which helps cause this way I don’t have to keep wasting steel ![]()

But I will fire up the air compressor and run Phillip’s files which should tell us if it’s a software issue on my end. That was the missing link in our troubleshooting so far and he did me a big favor creating those files this morning.

Not yet been away… At the inlaws filling in. Father in law in the hospital.

Have you checked z axis plug on the control box? Make sure power is off you can melt stuff don’t ask how I know.

I am uploading a video of your test cut as we speak, just check back for the edit of this post to watch it.

Here’s the resulting piece of that video though -

The tiniest bit of beveling, but will only get worse because your file still resulted in a .02" cut height which tells me it’s not a CAD/CAM issue on my end -

I did run multiple pieces however, and when running smart voltage, I had the same 93.7v I described earlier.

HOWEVER in the video above, I manually entered 120 and this time I had a slightly higher average voltage.

Oh and no one asked but I’m providing this information - yes the laptop being unplugged (on a separate outlet anyway) does not change voltage as I read that a ground issue can result in a lower voltage with a laptop plugged in.

Shit man, I hope it’s nothing serious. Lost my father in law this January, 3 months before we had our baby. Hoping the best for you and the family.

And if you’re referring to the VGA-style cable to the control box, yes that’s fine and secure. Nothing can accidently bump it and it hasn’t even been disconnected up until the day before yesterday when I replaced the coupler.

Thanks he has Parkinson’s, leukemia, caught covid. He is a sick feller going to be a long hospital stay. For now moving in the right direction.

Here is a second video run, however with Smart Voltage on.

Here is the results of the test piece -

The two pieces side by side, first one manual voltage and the second one smart voltage.

Still cut at the incorrect height; it maintains a low cut height after initial pierce just the same way the TAP file for cycling Z axis did.

I thought I was onto something as I did the voltage test in Firecontrol; had different results but the difference was specific to the “divided output” side.

Old VIM, with bad divided circuit, running raw voltage

New VIM, with good divided circuit, running raw voltage

So that peaked my curiousity, alas same results.

I labeled parts 3 and 4 as video runs as well because I did record a video for each one, but they are nearly identical to runs 1 and 2.

The “120v” means the voltage I entered manually, but was irrelevant and did not raise my cut height.

Phillip, I really appreciate all your input/help on this situation. Wish you the best with your family.

It is just one more futile exercise perhaps but how about changing the seeking speed of the z-axis to see if that illuminates something:

If somehow that changes your resultant cut height, I would blame it on mechanical or some electronic hiccup in the z stepper motor.

That still would not explain the torch rising at the end of the first cut. It was like all of a sudden it finally got a signal to say it was too close.

I know this is continuing to give you lots of things to try and may not result in anything but if you rotated that cut file 90 degrees, would it give that same result at the end of the run (torch rising) or would it give it just before the final few seconds?

I’ve posted a few videos and pictures as you were typing.

I hope you can look through them and see if anything stands out.

For now, if those edits are the first TAP file (the Z cycling) I will make those changes now and report back.

I am in the garage and can troubleshoot as the suggestions come in.

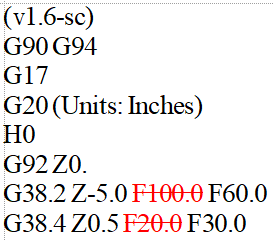

Saved the changes, you can see them in the lines below in Firecontrol.

Same result unfortunately.

Rotated 90, cut again, identical results.

I was agreeing with Phillip with “something loose” but you cannot have something loose that is “loose by a consistent amount of 0.020”! (My thoughts are now thinking some resistance in the wiring or calibration of where the stepper motor drive is at any given time. But, I have no experience in this field).

Hopefully, Langmuir will weigh in early this next week. Unlikely they will during the weekend. I see they are replying now!!!

Hey Everyone,

I’ll read through this today and brainstorm with the team first thing tomorrow morning!

Thank you Reilly!

Reilly, that would be absolutely awesome.

I am no expert in any field, but I am very mechanically inclined, have a digital multimeter and have experience with basic electrical work both household and audio equipment, and live 3 doors down from a licensed network technician/electrician that owns his own business if I needed help with something very specific that you guys need me to do.

Meaning, I’ll get my hands dirty as needed in trying to solve this issue.

I know my thread is very long, but I was hoping to be as thorough as I can be in every sense of the word.

@ChelanJim thank you I have had more than one extremely challenging family problems lately. I try to keep off the open forum. I will try to slow down later and reread through the thread.

Maybe you have already done this.

But, If you haven’t tried this…it wouldn’t hurt: