Crossfire XL with THC

PrimeWeld CUT60 (latest generation)

PTM-60 torch

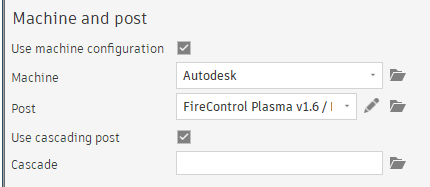

Fusion 360 for CAD/CAM

Rather unique one, and the only person I can think of adding to this is @AultFab since he had a similar issue.

@toolboy Since he and I are on the same page about this and maybe he can chime in.

Backstory - Ever since my bad VIM, I switched to raw voltage on my plasma cutter. I had gone through measuring voltage, pulling off my torch, etc. when I was troubleshooting. This is relevant as you read on below

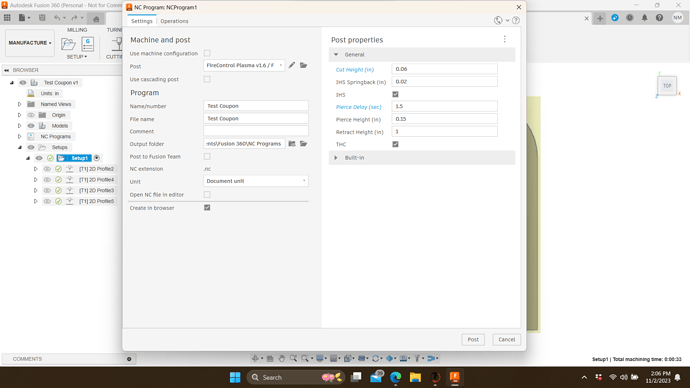

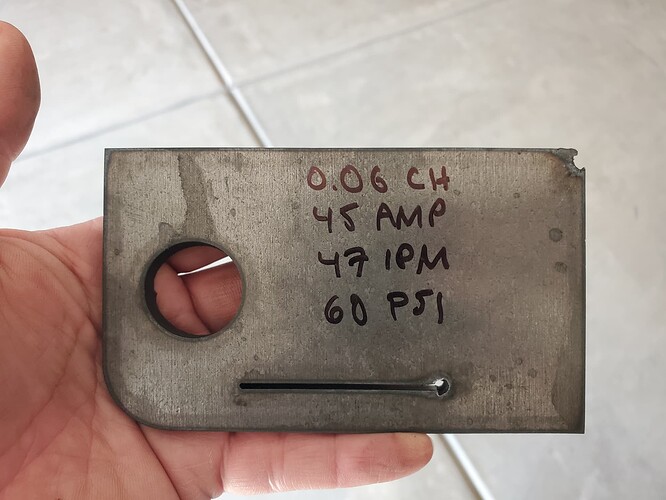

I know how to set my correct programmed torch height, as I did so when I first set up my table in Dec/Jan. To achieve an actual cut height of .06" my programmed height for post processing needed to be at .0545" and that gave me no beveling and smooth cuts.

With that said, I have a new UPM-105 coming in tomorrow to replace my PTM-60. Just for kicks today, I decided to just run some test pieces in anticipation of doing so tomorrow on the new torch.

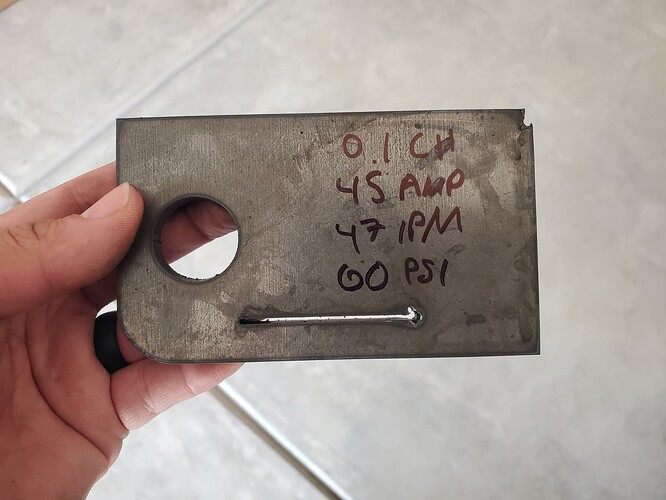

That and because I never confirmed my cut height after reassembly from my VIM issue, I thought I’d play around today.

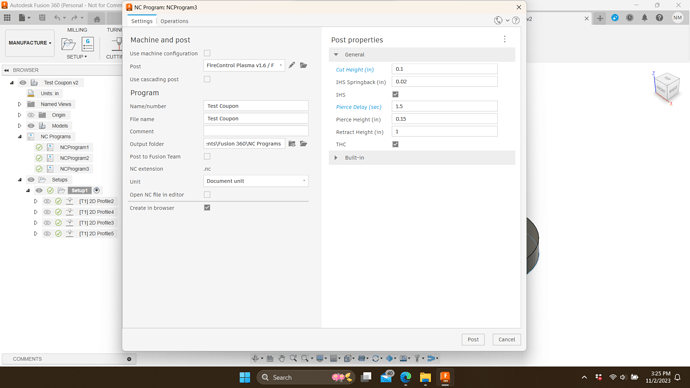

How is it that my cut height is .020" whether my programmed cut height was .0545", as well as .0745", and even .1"?

This tells me something isn’t “changing” whether it’s in Firecontrol or Fusion.

My Fusion 360 defaults have not changed at all the entire year and I’m referring to springback, and other items not messed with. Only thing I ever change are pierce delays based on thickness material.

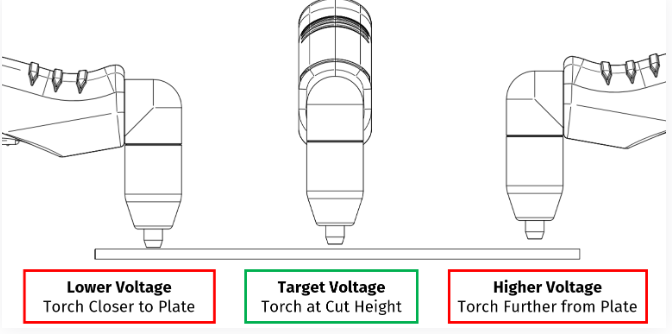

In Firecontrol as my g-code runs, it will state in the command list the ‘programmed’ cut heights I’ve used as stated above. Smart voltage is on and reads at like 87-88v when it was cutting 10 gauge during my testing.

My torch however, cuts without issue whether I have THC enabled or disabled. So it’s not a firing issue, air pressure issue, nothing like that.

My cut height simply does not change based on programming changes.