Used my dremel and milled some parts for my drone

Nice, that is a great way to get extra use from your table. ![]()

@maxxice - you can’t just post a teaser like that. You are going to have to tell us how you did that. Details man. Details.

I mean, to be fair, he’s obviously just bolted a dremel to the machine. lol.

But, I’m curious how you milled 1/4 inch aluminum with a dremel?

Do any of y’all Hypertherm users (non-sync) find consumable life to be any different running shielded vs non-shielded fine cut consumables?

I accidentally had Baker’s Gas create an invoice using the wrong deflector (220955). It was only $10 so no big deal but wondering if I should run with it or opt to buy the shielded deflector (220948).

Slowly, very slowly. Well, no, you have to move quickly, but very shallow cuts. And then there are the specially coated high angle end mill bits you need…

Neither of them extend beyond the nozzle so I don’t think it matters. The 948 is meant to go with the ohmic retaining cap. I don’t think it affects consumable life. I’ve only ever used the 955.

Right, but the caps are essentially the same (ohmic and non-ohmic).

I don’t cut thin stuff much as several here know I’m NOT a sign guy @ChelanJim but in the off chance that I need to cut 16 gauge, I’d rather do it as best as I can.

Word on the street though is that some people have better luck using the regular swirl ring on their fine cut? Sucks I bought a fine cut swirl ring if I should just stick to the regular one.

I used USG freeware

The purpose of the fine cut swirl ring according to Jim colt from hypertherm, was to help mitigate some trouble some people had with misfires I believe. He said there was nothing wrong running either but the design of the fine cut swirl was supposed to fix an uncommon issue.

Makes sense, thanks for that!

I’ll have to find the time to try them out. I’ll be following the slow cut setting but I hate how results are different on small test cuts vs larger intricate designs.

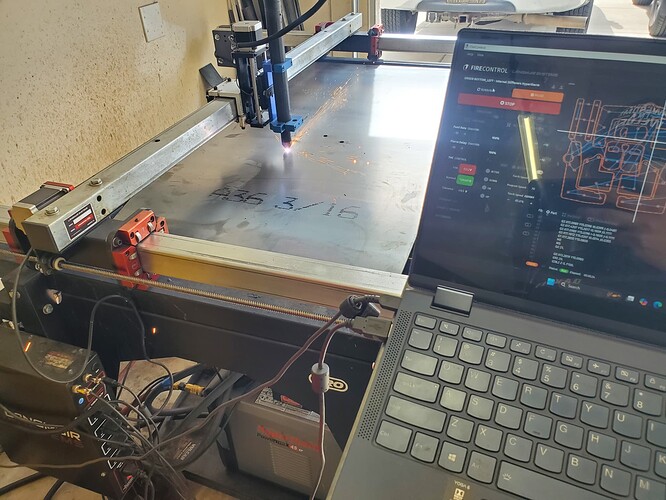

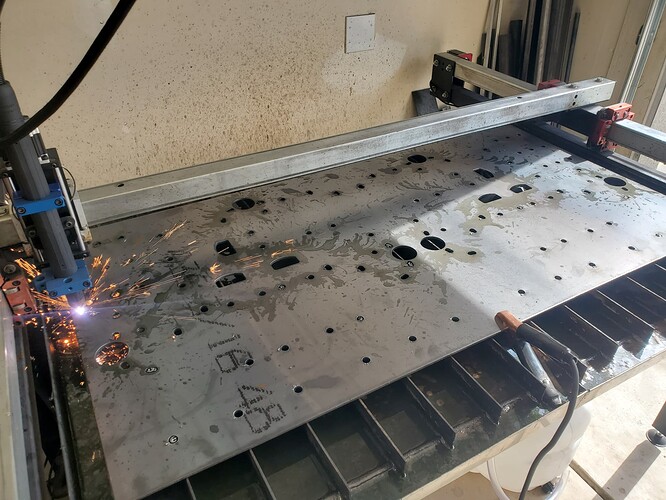

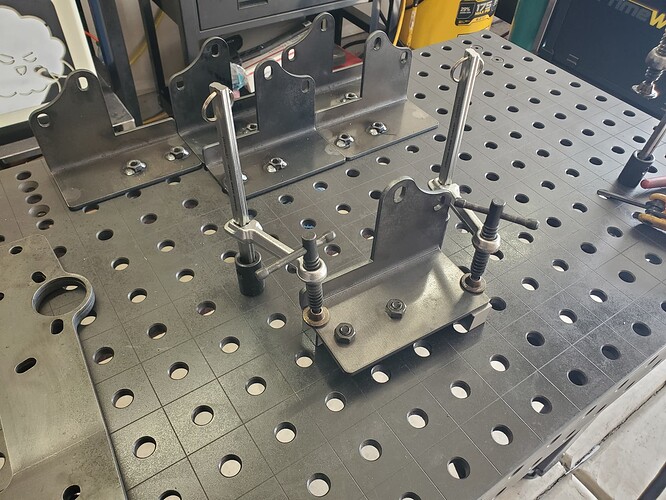

Boring production; at least it has resumed after that whole 2 month fiasco.

4’ x 2’ sheet covers 3 sets.

So, 6 sets are ready to go.

I just do 3 at a time though.

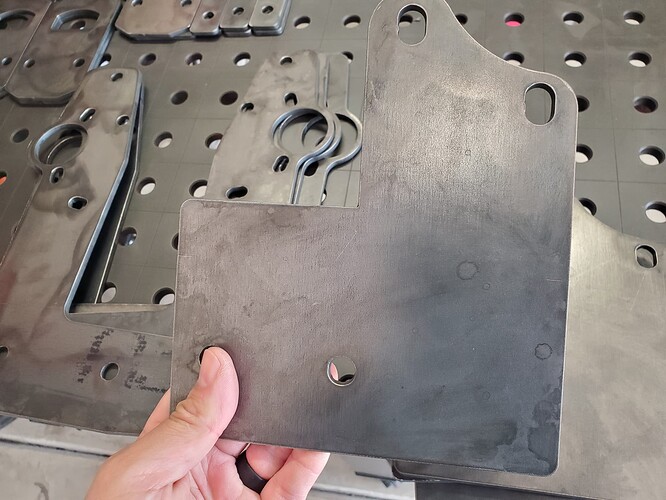

Am I the only one that enjoys stacking cut parts?

I like how they’re about perfect from one another.

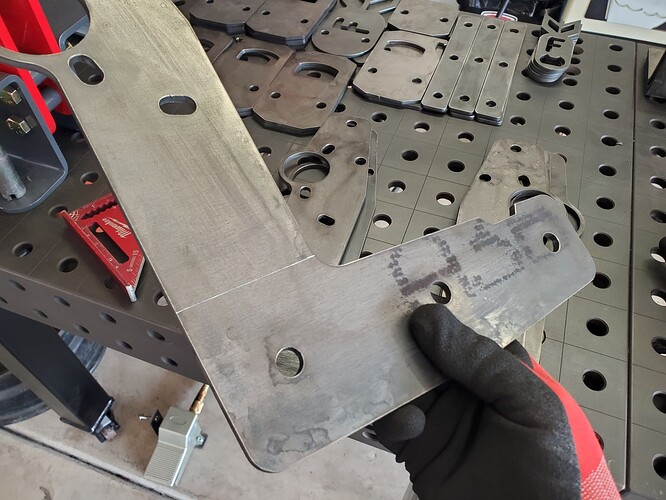

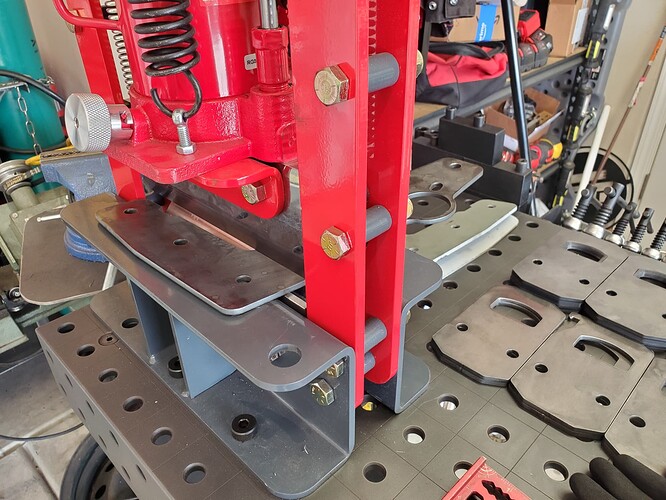

Being poor means having to scribe your metal for bending ![]()

Seeing as how this one gets a shallow bend, I use the lever to bend it manually on the brake.

All parts bent, now ready to weld.

Easy day, so I’ll bend and weld the next 3 tomorrow then ship them off this Monday or Tuesday.

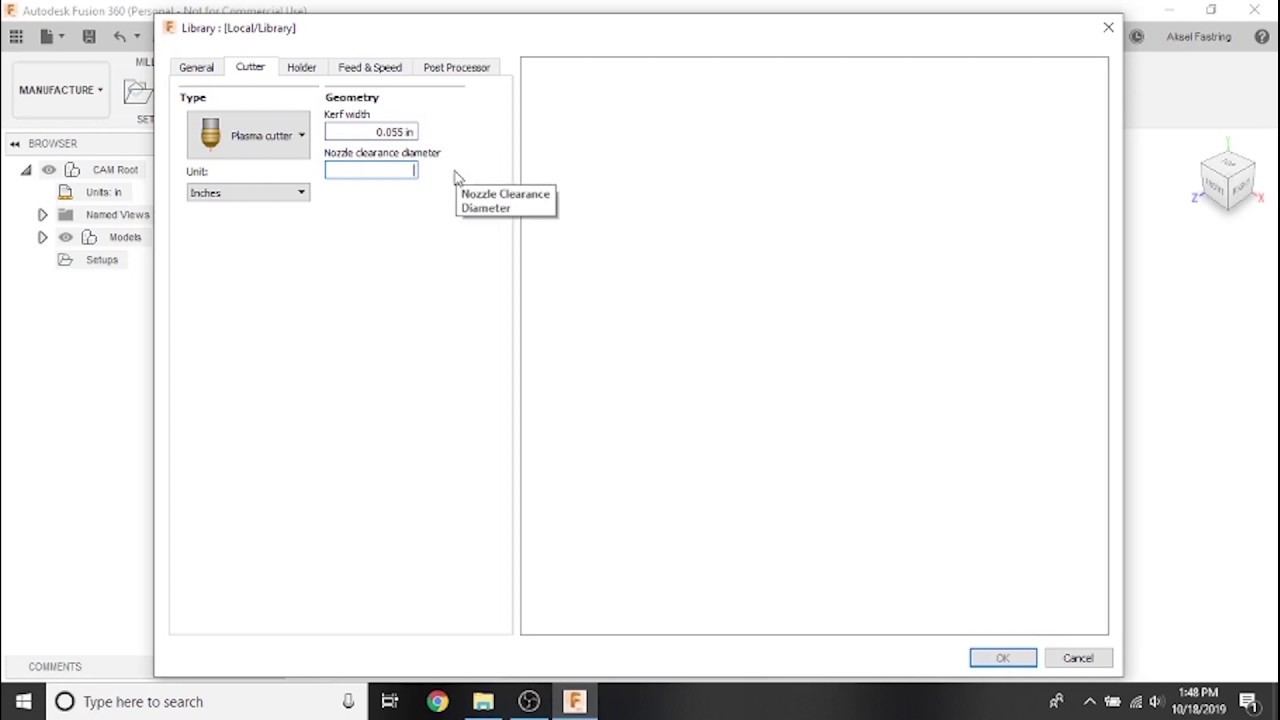

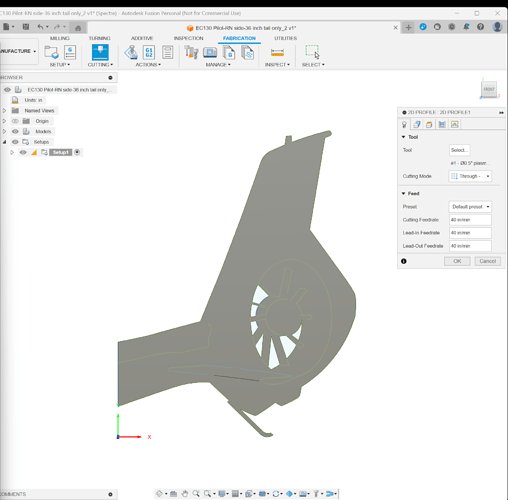

Put my Table back together after moving it 2 months ago. Sat down to finish a 42" EC 130 Helicopter for a retirement gift… Well the latest update of Fusion Deleted by Crossfire from my tools library. So now I’m looking for the instructions how to add the table back into the library… One thing or another…

The library is found locally

Yes, Fusion is cloud-based but I found out long ago that if you want/need your tool library copied over to another computer or something, you take the file from your local machine and bring it over to another PC.

My problem is Fusion kicked my table out of the library and I do not remember where I stored the file on my computer. So I’m going to need to redownload it. If I would stop watching videos I will find the download and get it back… Thanks.

I’m probably misremembering or using the wrong terminology.

Are you actually logged in? I know silly question but Fusion doesn’t just delete tool libraries unless someone else did manually.

Can you confirm you are in the correct directory? You have the ability to browse around when you click Tool Library.

As for the file itself, you won’t have one unless you manually exported it.

I did for myself but simply to place it on another computer, otherwise the only tools that’ll exist are those in pre-existing files you made that have the CAM process done up.

If you can’t find your library, it’s best to start going through old files, taking down notes for speeds, and kerf width, and create a new library with that information.

Doesn’t take long at all, maybe a few minutes.

This is the information I was looking for. I was confusing the “Post Processing” file with adding a tool. When I look at my Tool Library under Manufacture → Fabrication → Manage tab my Razor Cut 45 is in there. But When I try to select machine in the Setup. Everything is completely blank.

I figured it out. Thank you It’s amazing how much you can forget in 2 months. You would thing over 100 items programmed and cut I would not be drawing a blank.

I was trying to select a Machine under the “Setup”. What I needed to do was select the Razor Cut 45 under the “Tools” tab and the 2d Cutting profile.

Thanks for asking questions and getting my brain going the right directions.

I’m trying to do a test cut of the tail sections to see how it looks before wasting a whole sheet.

Happens to all of us!

My table was also down for 2 months as well! Just got up and running like a week ago.

Now I need to finish the control box for my Power coating oven 7’ Tall x 4’ deep x 40" wide. Just need to assemble the ceiling and do the control box… Thanks again for your help.