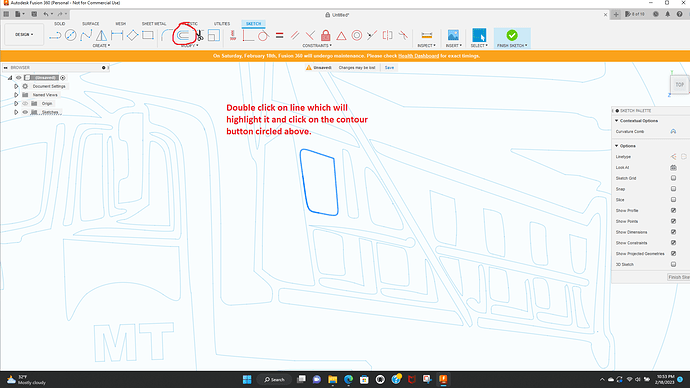

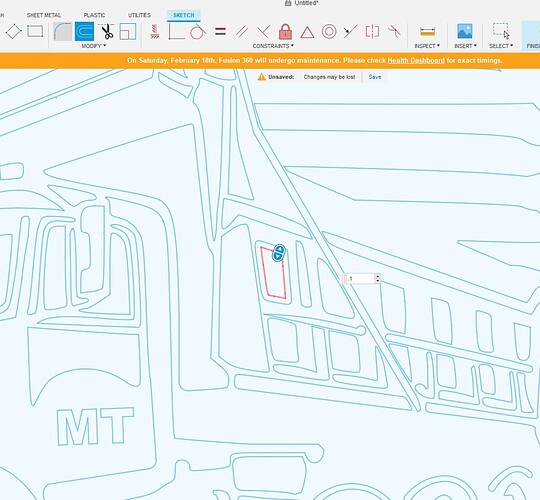

Sometimes when you contour the lines get it breaks them in corners so you have to find the break. After you contour them go back and “double click” on original line which will highlight it and just hit “backspace” The line will be deleted. GL

That front wheel gets crazy if any changes are made. I may just redo it completely. I’ll check those other areas again too.

The grille was one of my concern areas but it cut fine, as did that fuel tank area.

Thanks.

The wheel is my fault, the drawing I started with was very plain, I wanted something that popped a bit more! Lol. But it is intricate.

@DnKFab Yeah, I hope you don’t think I was being critical. There was one gap at about 1 o’clock that was too narrow for my kerf width. I tried several fixes, but it just kept blowing up. I finally deleted that section and copied the one down at 7 o’clock, spun it around, and it fit perfectly.

I love the truck. I can’t wait to get one cut out for my friend whose son has the company. He’s goanna love it.

@Wsidr1 I’m not taking it as criticism at all. I’m flattered at the effort you have and are putting into it. I don’t know if you have already tried this or not. But if it is 14 gauge or thinner I typically use as short of pierce delay as possible and never any lead ins or lead outs. I find my kerf widens significantly during those action or anything more than bare minimum pierce delay.

It’s great to hear what others are using for setup. What works for one person might not for another due to machine and setup. Only way to know is trial and error. It took me months to get things how i like them and always trying new things people say to see if it’s better. i do cut most things out of 16ga because its reasonably cheap. I have cut metal up to 1/2" thick so far with my hypertherm 45XP and cuts it like butter. The thicker metal seem to cut better due to heat dispersion.

i walked out to my attached garage and seen i have spray paint cans in a big bin so figured i would design easy paint can holder. I’m going to make a few lengths and i’ll post in little bit. if others need cheap simple wall paint can holder

I made this for a friend that runs the flea market. I get these used trowel pans from work. They are used on the riding troweling machines for finishing concrete. 3’ diameter. Any suggestions on fixing the 9 and 8? I may just leave them or try and weld a little piece in each but have no intentions of cutting another sign.

Is that Elkhorn KY? Famous kayaking country if so. In my younger days it was on my list but never made it there.

Elkhorn WI on the WI IL border

I live about a hour from there. The breaks interstate park is close by as well.

They release water from the lake in the county I live in is when the water gets right.

I ended yesterday blowing out a tip due to a failure in my air dryer. I got that fixed, was a simple fitting that allowed air to bypass the desiccant. Put a new nozzle on and could not get machine to cut more than 3 inches consistently. Today I began the day trying to figure out why I could not cut more than 12inches of 5/16 plate without crazy bevels and failure to fully cut through the metal. I spent about 12 hours today. I was having terrible beveling. I changed my thc from out the receptacle on the back of the machine to the raw on the front lugs, I set, checked, tested, and reset cut heights and pierce heights a dozen times, I deleted and reloaded sheetcam. I built a new desiccant holder to dry the air further. I went through 6 or 8 brand new nozzles. I took apart my torch to make sure it was functioning properly.

I have my consumables in little individual drawers. I have been running at 48 amps. I have been grabbing tips from the 50amp drawer. I ran out of 50 amp tips and just decided to grab 1 60amp that I had. Everything began working flawlessly. Perfect cuts. Turns out, the nozzles I had were marked in mm rather than amp rating. I had 40 amp rated nozzles in the 50 amp drawer. I had been blowing out the tips all day and chasing my tail because I kept putting undersized nozzles in the machine!!! All well, ultimately a learning filled day. Here is a video of the machine working after I finally got the correct size nozzle in place. Ever had one of thos DOH!!! days? I sure did!

Personally, I think your 9 and 8 look fine. If it were the company name or logo it might be different but with the date, no one would doubt what you meant. Nice sign!

I have tried this technique when I thought the lettering might get lost with the bridges toward stenciling (of course I know you do not plan to do another sign):

Haha. I did exactly the same thing yesterday. Sat I had cut some 3/8", then changed tips and cut some 18 gauge (see above failed triaxle cut). That was Sat and I got pi$$ed and shutdown the machine.

Guy called me yesterday and wanted more 22 caliber targets cut out of a piece of roughly 3/8" he had brought me. Sure. No problem. Cranked amperage up and started run,…realized it but FCtrl was already frozen (happens to me all the time) so I just let it continue. It did okay but got damaged enough that it failed to cut through in several areas, but it was toasted afterwards. So was the electrode.

Thanks ChelanJim it’s always nice to get different ideas

wow boss… you got some settings dialed in! I always have trouble with stuff that “fine”. especially with warping (cut speed vs quality, etc). But I haven’t tried any fine cut stuff on my new Hypertherm yet, fingers crossed I’ll work my way up to this quality level with such fine details.

For some reason that’s just a Primeweld thing. The new Everlast will pierce 10 gauge at 0.3 seconds, and I’m thinking I probably need to try 0.2…

Regarding your freezing, I have a couple of thoughts. I will DM you. You can share them with the group if they wind up helping.

I ran a trial today on advice of the forums top diagnostician, @CrazyCasey ![]()

I am regularly having problems with FCtrl freezing during cutting. Typically, my program keeps running, but all display and screen controls lock up until 5-10 seconds after the cutting has stopped.

So, on his advice I isolated my work piece from the slats and ran a 800 line program. No freeze up!

Now, I need to run several larger programs when I have more time in order to know for sure this is a “cure”. Then, I will figure best way to isolate. Maybe remove tray and place rubber strips between tray and table…?

I know I read in your thread about a separate, dedicated. ground to the table. Might try that first (easier).

Far out! Rubber on the tray won’t work, because the water/fluid will conduct. But now you know your problem is because voltage from the arc is getting to the electronics…somehow.

PS, @ScottNH is the Jedi Master who came up with this diagnostic step.

***Also, @langmuirsystems told me these freezes are exceptionally rare, but there are a lot of folks over on the Facebook “Support Group” who seem to be having similar or related issues (and they all seem to be running FireControl v21.1.4 or v21.1.5. You should start a thread so we don’t convolute this one. ![]()

I would call that a troubleshooting method not a solution. We need to come up with the next steps for isolating where the emi is getting picked up and brought to the box or the computer.