Made great progress this afternoon

Memorial Day project…mini chimney for those long days of smoking that I only need a few hot coals…and just because I can. 3.5”x3.5”x6”

Not forgetting my father that passed from the effects of Agent Orange a few years ago, he left some money that enabled me to build a garage and purchase my Pro. He was always in support of me doing creative things.

I know it isn’t thanking him. I thank him for the sacrifice and the rest of the family for the sacrifices you all made

Finished up the shaman panels today, added his arms with hands ( I’m thinking he needs different hands, these are modeled after my hands and they’re not quite right ).

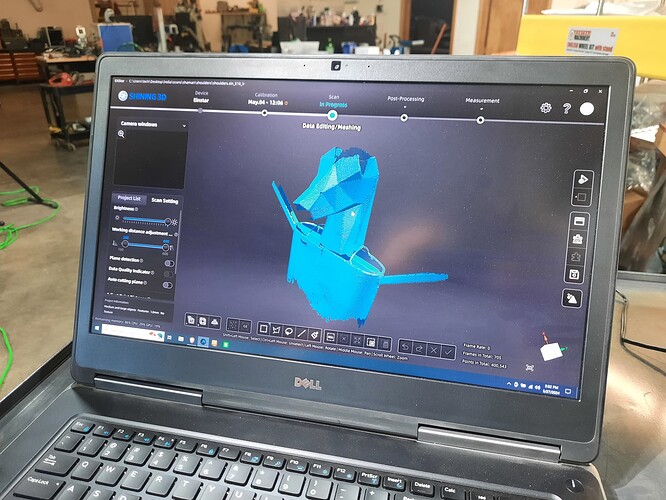

Shoulders are next. Got out my Einstar 3D scanner and got a great scan.

1.9M facets, my 6 yr old laptop is a little sluggish but it’ll do.

Awesome man!

If there are going to be some shaman offspring, looks like a great re-purpose for an old auto muffler to be used as the body.

Cut this over a week ago, just never posted it because again I forgot to switch my nozzle out half-way through the program

I accidentally left the 65 amp (1.1mm) nozzle instead of switching it over since I had done some more 3/16" the day prior

Heading out later to grab some 18 gauge and I’ll cut this one out again along with the second layer

Sits at just 13.5"

Oh he’s nowhere near done yet. He gets a lot of Shaman bling, just wait.

Speaking of forgetting, I bought those three sheets of steel last Friday. I pulled out the hand torch to process. I had the air pressure set at about 70 psi for the machine torch. I couldn’t get my hand torch to even fire at first, but then when it did it blew the end right of the electrode and ruined the tip and blackened the swirl ring. ![]()

New consumables and air pressure at 45, cut like butter.

Dang

I normally don’t change the air pressure when using my hand torch, but if I do it’s down to 55 from 60 or 65

Wyatt has a strong arm…

Not so much a shaman as a wendigo

I cut out my backplate and threw some rattle can at my Tombstone sign.

I may still add some color to their hats and maybe paint on belt buckles or some other small touches, but basically finished this evening. Another simple sign that will look good on my garage wall until I give it away to make room for…

I know there are many Hypertherm users here, but I’m one of the poors using a CUT60.

Before, I was replacing my nozzles around the 400 pierce mark while running my electrode close to 800 (two nozzles for every one electrode). At 400, the orifice was quite oblong and would cause noticeable beveling on 1/8" or thicker. It would still cut anything I needed it to though.

Since running refrigerated, I thought I’d see what 400 pierces looks like -

My concern was that my air compressor wouldn’t keep up as well with the added filtering on account that any item between it and the plasma cutter acts as an inhibitor.

Well I’ve left everything in place and I’m already seeing a huge improvement in pierce count.

Replaced them anyway so I can properly assess before and after figures.

These are cheap PrimeWeld consumables.

Not a Darn thing. I can’t trust it not to ruin hundreds of dollars in material because it screws up mid cut.

I don’t know if we can help, but we need more information.

What and how thick is the material

Your settings

Your plasma cutter

Air pressure

Description of the actual problem. Mid-cuts are not any help.

Has the table ever worked before

Etc

It’s pretty late, but we have some great troubleshooters on the forum.

Like @Bigdaddy2166 said, you are missing a wealth of information that can help to diagnose your issues.

I’d wager a good 98% of all issues are the fault of the end-user; don’t take it the wrong way when I say that because you can’t be expected to know how to work everything 100% from the get go.

Do some troubleshooting, conduct a search, post a thread here, whatever works for you but there are tons of people willing to help.

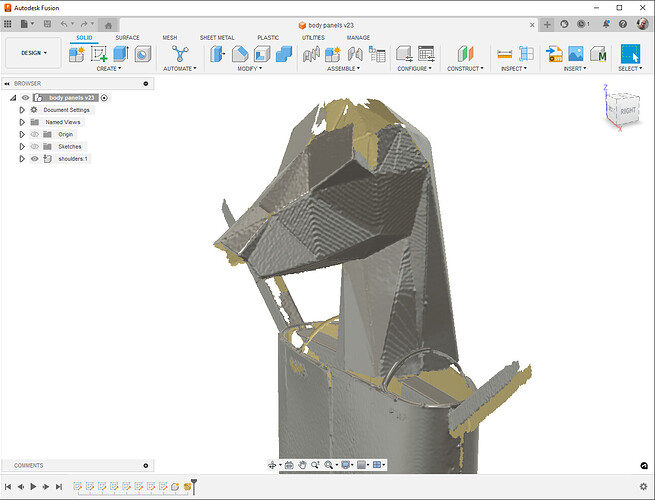

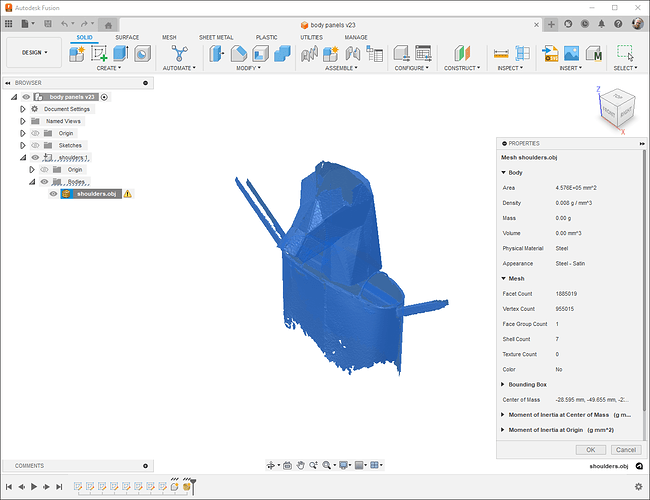

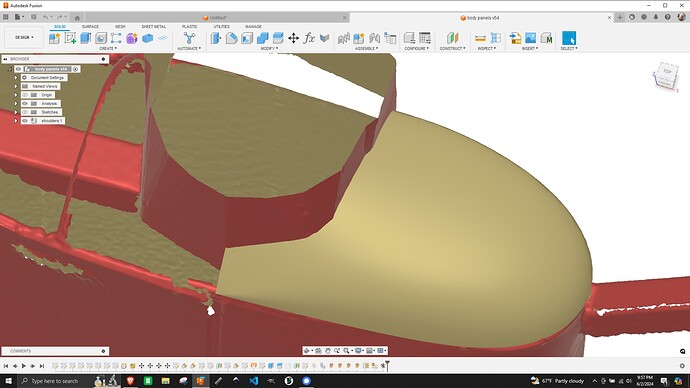

I’ve had a 3D modeling challenge that I spent a couple afternoons on. My shaman has a low-poly head and I want his shoulders to be more of a curved surface. The problem was how to split my modeled rounded shoulder with 3D scan mesh data with 1.8M facets. I tried about 6 approaches using F360 tools and blender. Finally got it, I’ll whip up a short video showing the approach only using F360.

To check the body split, I 3D printed a portion to check the fit up.

I need a tight fit up to keep those damn wasps out of my shaman. I’ll make a video showing how to model his right shoulder and post soon.