nice work.

Sets the bar pretty high for the rest of us!

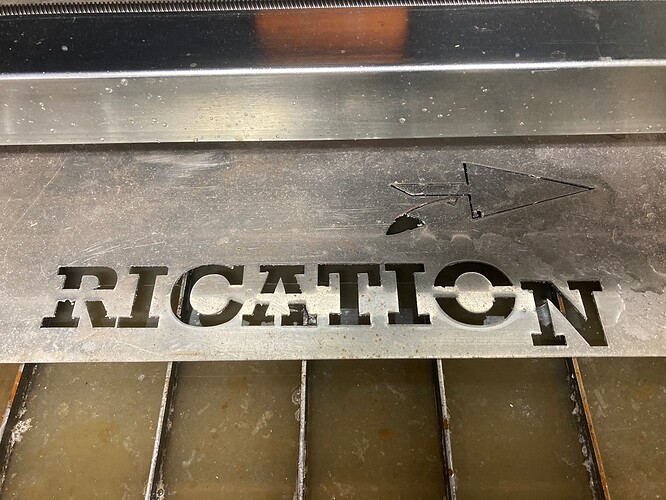

My second cut and first attempt on my new logo. I think one of the screw drives slipped and caused it to jump out of alignment. I added locktight and retightened them all really well. Got this done.

I haven’t cleaned it up at all, some of the dross on the back pulled off by hand and I only had a few issues. There were supposed to be veins in the feathers but they were too thin and got cut out, had to skip the cut in FC. Then the last cut across the top from right to left stopped about 10" in and I couldn’t get it restarted. Wrote a quick straight cut in FC to finish it. I will get back to it in a few days and see how it cleans up. I’m super excited for my first “successful” project.

That looks really good! With regard to the area along the top (above “S” & “P”), you could just trim a small piece off all the way across the top to smooth it out. Straight line cut.

Were the veins in the feather just single line cuts? If so, you’ll need to create a separate tool path for them. If you need help with how to do that, start a thread in the software thread of your choice and you’ll probably get help pretty quickly with how to get the veins to cut out okay.

Thanks. They were not single line cuts but they were their own path. Still trying to figure this all out and appreciate the advice.

If in the drawing the cut width of closed loops are less than 2 x your kerf width that’ll usually cause the toolpath creation process to discard those cuts. At least that’s what happens in Fusion 360.

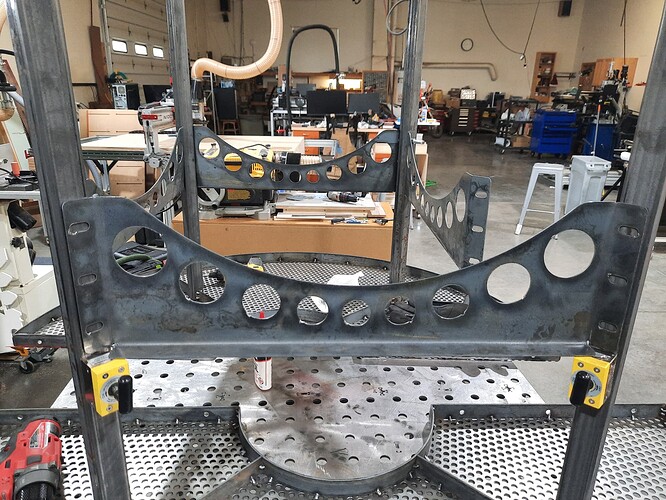

cut and prepped the last four shelves yesterday evening.

The CFP is running great. Had an issue with THC stopping the cut. Turned it off and finished plate/cut 2. On the next two it worked flawlessly. I suspect something to do with the height of the material variability? It’s odd that it was erroring out, then a few minutes later works great.

I did just go through and clean everything and oiled the ways and transmission. It didn’t get stuck at x>40. So, keep those bearings clean! ![]()

@mg6studios Make the video a short as well and you will get a much farther reach. People love doom scrolling.

I was a workin’ fast as I could! Done. Shorts are harder because have to create on phone first.

Here is my very first project cut after getting everything up and running. I had some THC issues that I had to troubleshoot, but everything seems to be working now.

I then made my first design and did a small test cut. Owe a thanks to @ChelanJim for helping me out with creating the DXF and some things I was messing up.

Great 1st cuts!

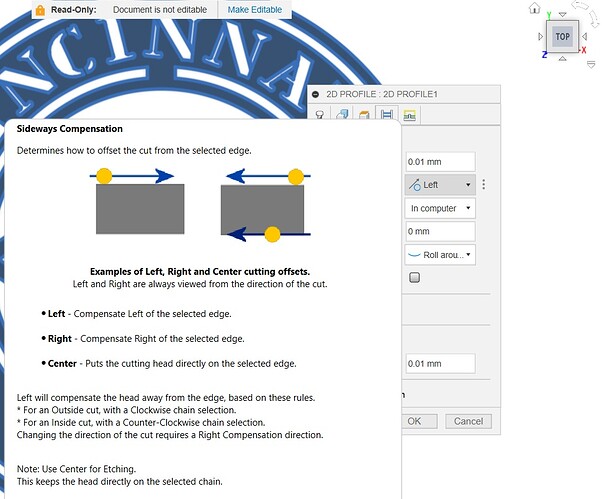

On the buffalo, that pierce point under the tail looks like maybe the parameter was set to “Center Compensation” (vs Left), meaning the cut followed the center of the line instead of the outside. If so, that will make your parts cut a little smaller than expected, should you cut something where the dimensions are critical.

In Fusion360, here is where you would check/set:

Thanks for the great info.

Unfortunately that isn’t a pierce, it’s just me being sloppy with a 3 point arc that got too round and I didn’t notice. I’ve since shrunk it down and it should look smoother on the next cut. I’m making it full size for my road sign this week.

Here is the full size cut from 12ga with the tail to leg corrected. It still might be too round but don’t think it’ll be noticeable from a car. It’s about 25x24

Got my garden tree table finished this afternoon. Cut some gussets and bolted it together around a tree. My wife loves it. BTW, she loves rusty steel, so no paint on this one. When the flowers bloom, we’ll be ready for a garden party.

@holla2040 that table turned out awesome.

Thanks, I’m surprised it came out as designed. Hardly ever happens. Maybe I’m just building some skills.

Awesome.

I think you need to do a walk around video to show all the items you’ve put in the yard and garden!