Love mine! Yes it for all my metal prep. It’s hard to keep up to @Bigdaddy2166

How did you move that around while working on it and how did you ship it?

What do you think it weighed?

Very nice work!!!

Beautiful, but my back hurts from looking at your pics.

Nice work though!

Wasn’t that table featured in a James Bond movie? meeting room of SPECTRE: ![]()

![]()

Very impressive, even if it is not the same table!

That looks great! Nice work and thanks for sharing.

So I built each base on wood stickers so I was able to push my harbor freight jack cart under them when they were done and cart them around the shop to lay them out and build the frame. to get them on and off the cart after that I just tilted them up from one end while my wife pushed the cart under them. loading them on a trailer was the easy part. i just jacked the cart up to the trailer height and slid them onto the trailer. I delivered them to the powder coater and they have a forklift. after that my burden was done. It was built for an office furniture company and their crew had to carry these bases up to the third floor on the staircase because they would not fit in the elevator. They are the real hero’s.

Based on the math each base was about 370lbs each and the frame for the top was around 250 lbs but it was also in 3 pieces. about 1300 lbs total not including the 2" thick oak top.

It was a fun project.

Dang I forgot about that table, I thought for minute that maybe I held the world record.

WOW Nice work

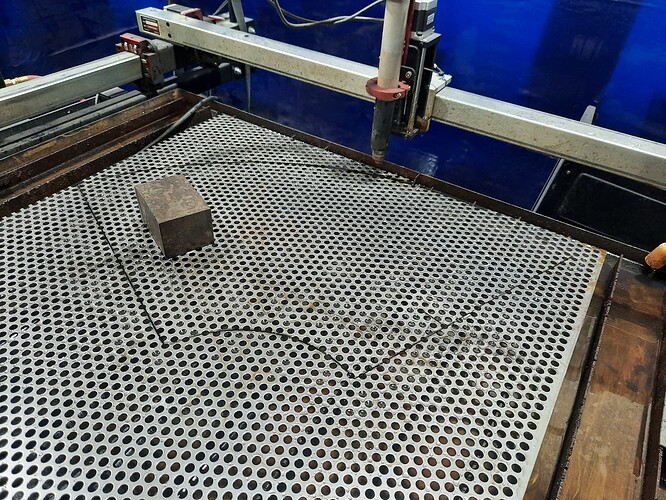

A few knife blanks for our blacksmith friend cut from old bandsaw blade.

The material was warped all over the place. Before I got the pieces they were heated and beat “straight” . I ran them through a roller and got them a little flatter and then tacked the pieces to the cutting table. There really wasn’t enough room in between the pieces but I cut it like that anyways. Had a couple little bites in some of the pieces because of thermal distortion but all in all it turned out pretty decent. Sure gave the THC a workout.

That’s another expensive hobby I have wanted to get into for a while.

This guy earns a living doing it. I bet you those knives will sell for 2 to 300 bucks a piece by the time he’s done with them.

Can you get a picture of the finished product. We would love to see one. You know since it was cut on a LS product.

My dad made 15-20 knives from old band saw blades BEFORE I got my table. Used deer antler for handles.

Now that I could cut them to shape for him, sadly, his health has taken that hobby away. But man those saw blades make some great knife blades.

Haha, us here at Langmuir want to see the finished product also!

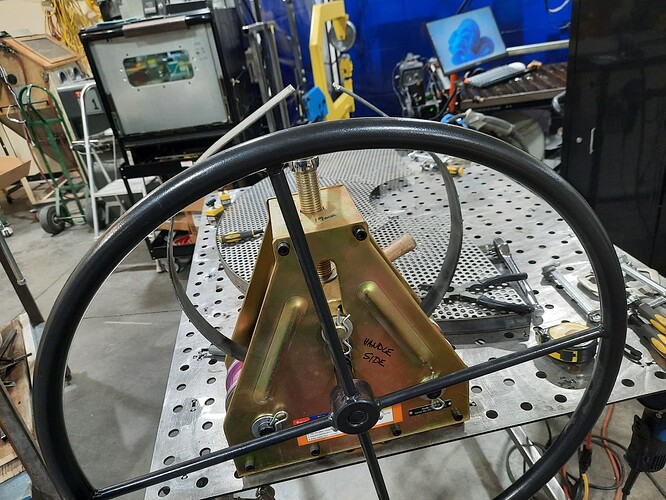

Working on a wrap around tree table made from perforated 14ga. (See my other post about perforated cut problems). Got half of the top fabricated this afternoon.

That’s gonna be cool, and you get to both cut and weld on the same project! ![]()

Can’t wait to see the finished product.

Sure, I cut and weld projects all the time. I’ll keep you posted on my progress.

What do think of the Harbor Freight roller?

Are you asking me about a roller?