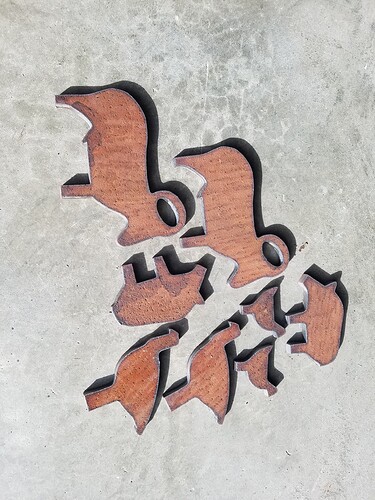

I would not go higher on pierce delay. I think your cuts look pretty outstanding! good job. On 16 gauge, especially at 30amps I have found the minimum pierce delay to be .4s for my set up. A lot of my designs depend on smallest most consistent kerf and many times it’s not possible to use a lead in. I use sheet so i set my lead in to 2x’s my kerf and use the shortest pierce I can and still accomplish the cut. It is possible to shorten it too much and the electronics will throw a torch move before arc error. It’s my experience the longer you stay in any given spot the wider that kerf gets trying to find metal to keep the arc going. I use a everlast 52i on 16 gauge at 121ipm and 28 amps. I use 30amp tips, 65 psi. I can cut items like in the picture with a lot of confidence with a programmed .034 kerf. Your cut height if very critical for a consistent narrowest kerf and i program mine using a nominal voltage based on multiple test cuts.

Everyone has a little different setup so play around with cuts and see what gives you the least dross. Another thing that I don’t see much of is people saying using 0 degree lead -in. i do this mainly on my relief bend lines so you don’t get marks.

I just cut this one out for my younger sister. 15" x 19". She has a miniature pony she calls “Weeder” because she says eating the weeds is his only job!

Back side had almost no dross and I didn’t get any blemishes.

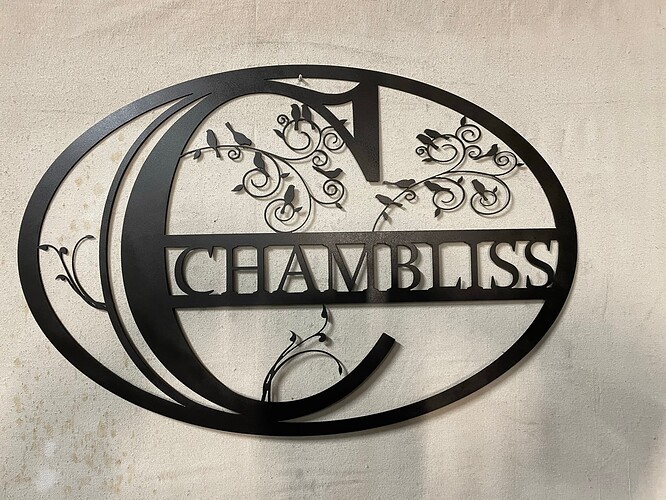

That is some outstanding delicate work on the Chamblis sign.

Hat rack, coat rack and Christmas tree all in one.

Ok here is my sign I was having trouble placing the text where it need to go. All done but 7 screws. Powder is a silver vein dark brown is wood. This was much harder than I thought it would be. Oh wait I always say that

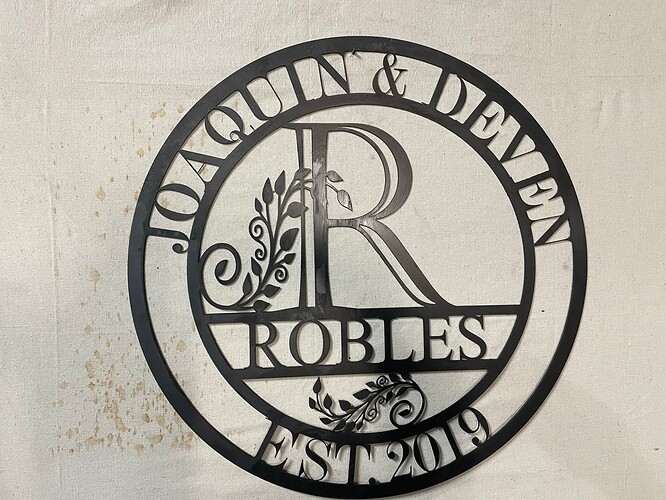

I cut one more sign late today for my nephew and his wife. Both Army vets. She is still active duty.

I wish I hadn’t previously posted it on Fireshare because it’s got a few flaws. Next revision will be good to go:

FYI- You can delete them from fileshare by going to your dashboard and deleting the project. Then you could reshare if you want.

I cut out some “NRA Silhouette” targets for a friend. I am not into competition shooting but he says these are official 22cal targets. I was happy with results.

7mm thick rusty steel. 50amps w/60 amp tip, 75psi, 1000mm/min, 1.2 sec pierce. I had the pierce set at .9, but had to increase it during the cut because the first one did not pierce completely. That goodness for that real-time update of pierce in FireControl.

Kubota fan boi here. It’s simple but it is the Kubota logo and font.

I posted it on Fireshare a while back and the image looked crazy. So, I downloaded it from there and cut that copy instead of my saved one. Came out perfect.

I had a late 70s or early 80s Kubota B6100D. It was little but mighty. I am guessing it is still going strong somewhere as it was a tank. It was before the modern rounded logo.

I’ve got 14 acres, with some woods. I bought a 2003 32hp back in 2007. Been an awesome machine and unbelievable how much work I can do with it. Perfect size for my situation.

To bring my comment around to stay on thread topic ![]() , I hope to get motivated and cut out a set of grapple jaws with my Pro.

, I hope to get motivated and cut out a set of grapple jaws with my Pro.

Brought the forks of the forklift over the table and burned 2 1 inch holes in them. About 3/4" thick spring steel. PW60 60amps 2.5 pierce time with a 0.4 wiggle on pierce and 6 inches per minute. I’ll snap some pics of it this weekend.

Being from that era, it was probably a “gray market” tractor, meaning made in Japan. They were/are definitely some tough tractors.

I traveled to Japan many times in my 25 years with Toyota. I regularly saw Kubotas out in the rice fields that looked ancient. It’s the most common brand. They work in flooded fields, so constantly wet and muddy. Some have steel wheels with paddle looking tread. Check out these pics. Man, I love tractors!

I’m going to try the truck later today. I am real nervous about it. I ran the simulation and at about 6:30 thats going to be the longest cut time I have attempted so far. I still have an unresolved issue where FireControl freezes on me. Recently it’s only been the display freezing and the cutter continues on, but this will be a big test/gamble.

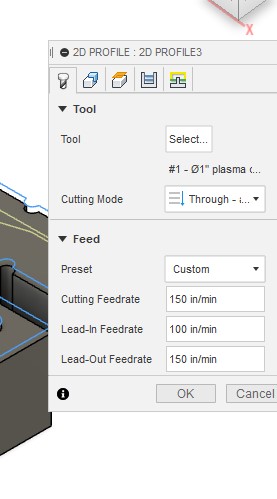

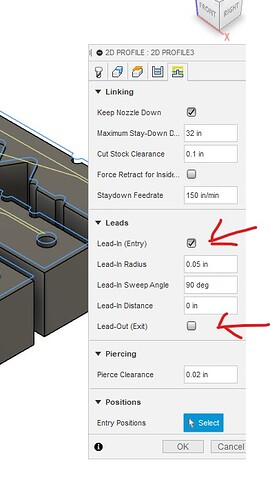

After reading your advice I am going to lengthen my lead-ins. I created my code with a lot shorter than Kerf x 2…

Just so I am clear, can you tell me your settings for the truck cut

:

Lead-In Radius:??

Lead-In Sweep Angle: ??

Lead-In Distance:??

Lead-Out same or different or none?

The rest of our settings for 16 gauge seem pretty similar. I run a little faster and hotter, but not much.