Nothing to fancy yet still learning cut out a few things from fireshare plasma stand for my cross fire pro and then the grinder hanger for my weld table i am building then made the first attemp at cutting some caster mounts out of 3/8 plate took a couple times to get my setting but they turned out ok besides i had my offset wrong

Useful stuff is why many of us initially bought plasma cutters, then CNC tables. That was my route to get here. The sign making obsession just kinda snuck up on me!

Not having the tools that you would like to have can suck sometimes…but you make do. Mig welded countersunk #10 screws to the letters. Studwelder or at least a tig welder would have been nice!

Thats as good as it gets nice work!

4 hours to make that? Is that from start of design to having it mounted?

I Wish I could think that well! Nicely done! Have you ever showed your equipment for engraving?

I finally got around to making a TIG filler rod holder for my welding cart.

Designed in FreeCAD, bent on a harbor freight 36" brake, dimple dies from Amazon. Made from .080" aluminum.

I still need to get some 2" black PVC pipe to finish it up.

I have that same tig welder.

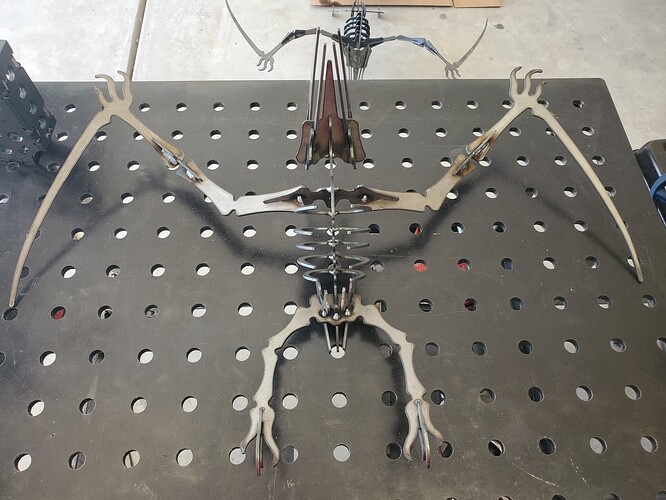

I know someone shared some links for some dino’s but I don’t think the Pterodactyl was included so figure I’ll add it here

Pterodactyl Nested.zip (63.7 KB)

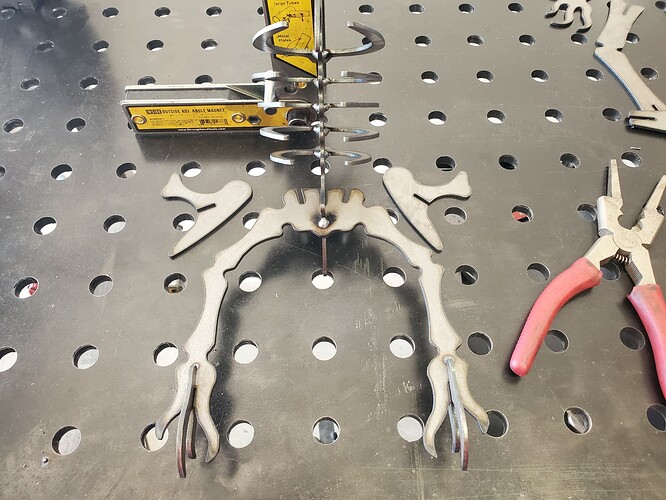

No instructions so use this as a simple guide; suggest separating into small groups like shown -

Here’s the skull, slotted in the manner shown. Go ahead and tack weld it on the backside -

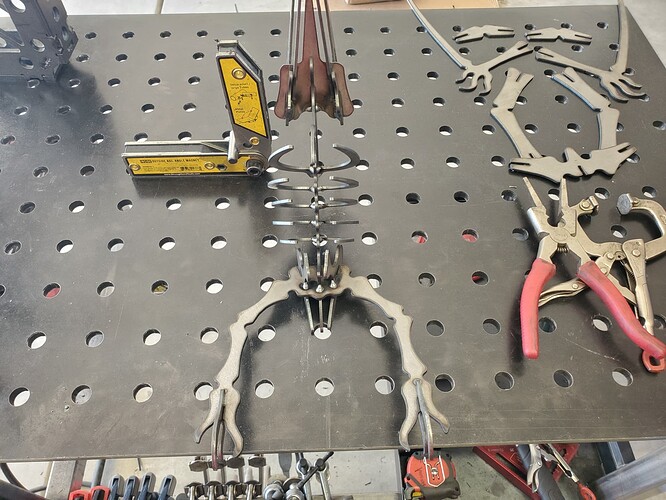

Now you can tack weld it to the spine -

The ribs go from largest to smallest, beginning at the second slot from front to back -

Set the assembly aside and start working on the claws by tacking them to the feet -

The spine assembly you set aside can now be tack welded with the leg assembly -

Next up, these pieces on the pelvis go on -

Time for the wings; I like to assemble things then flip them over for my tack welds -

The joints go next -

And finally the remainder of the wings -

That first slot we saved on the spine? That’s for the wings -

I’m sure you can find an easier way to do it but this allows fitting parts up easily without having to stick a torch in any awkward or tight spot for welding it together -

All in all a 5 minute job.

The zip file containing the DXF is not sized for any particular gauge metal. You will have to adjust the nesting and dimensions based on your own cut settings and desired thickness

Just like my 10 gauge slotted parts, I also run my 12 gauge slotted parts to give me .02" play for easy fitment -

Hey @Kwikfab, did you catch @TinWhisperer excellent video on using Slicer? Probably something you’d enjoy and want to acquire from Autodesk. Slicer, I mean.

Twitch (and youtube) Live Streams CAD CAM - Software / Tutorials - Langmuir Systems Forum

I rarely jump on this forum (hate the layout/formatting)

But that video is super cool thanks for the tag, I’ll have to mess with that one day

I agree this is a difficult forum to navigate…

I guess it what you get used to. This is the easiest for me and everything other one is hard

That is a super share and a great write-up. Thanks!

Hi Nelson,

This is really cool, thanks for sharing! If you post this as its own thread in Projects, I can pin it ![]() . This is a pretty monstrous thread, I’d hate to see your post get buried in it.

. This is a pretty monstrous thread, I’d hate to see your post get buried in it.

Will do! Didn’t realize that section existed.

Great idea Reilly!

And you are right…so many different and good things presented in this thread but how could someone find them all?!

HOW TOXIC IS THIS SLUG?

I live in the country with a septic tank, 40 chickens, a 1/4acre garden and stream that runs at the back of my 10 acres.

My analytical brain tells me its metal dust, borax and alittle WD40. However it looks way worst.

How are folks disposing of the liquid when doing a change over?

Im switching to Sterling Cool and doing a 2 tank system after I install the sink drains. Tank 1 is a settling tank and tank 2 will pump fluid back to the table.

Thanks in advance for your disposal thoughts. I dont want to poison my animals or garden (myself)