Amazing attention to detail!

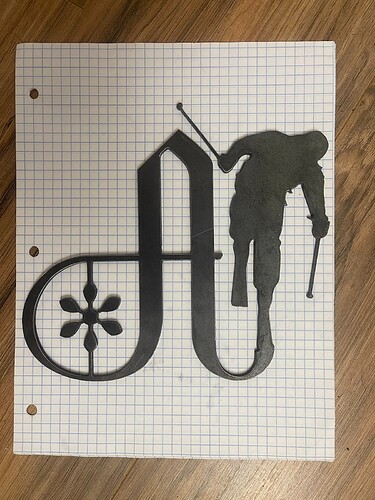

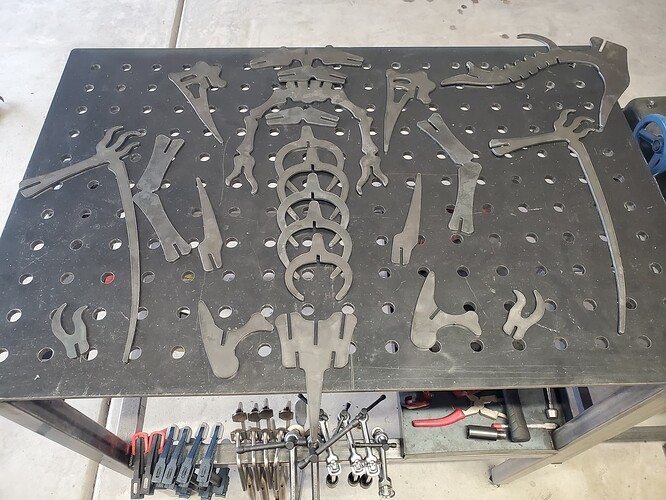

My first couple attempts at cutting some purchased files after having some air issues now to learn a little more on designing my own stuff

Looks like someone’s been bit by the bug

Nice, clean cutting even on the finer details. Great start!

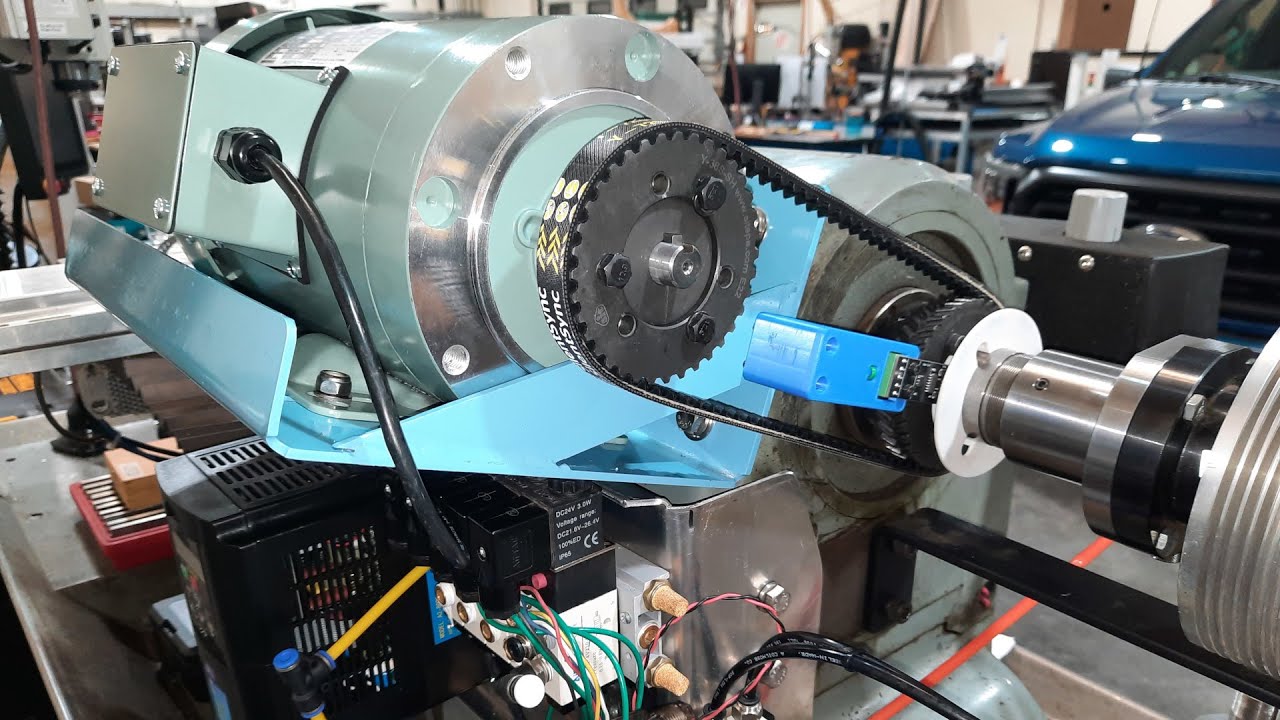

New T better then the last one more detail. Its the Ebay guy For $15 it is very reasonable the guy sends a usb stick and lots of info. This is why I cant finish the damn dog. ![]()

I bumped up the big one 1.35x original size this is about as big as I could with a 3x4 sheet of 10 gauge it ended up being a little loose but I planned on welding it anyway. Any bigger all the slots will need to be adjusted. Also any bigger 10 gauge will not be thick enough and the file will have to be chopped up to cut pieces. I am taking a break from the Dino world for a bit.

Much simpler than a lot of the awesome stuff on this forum but if I took anything from What About Bob… Baby steps.

Lol looks good but like I said, just make sure your table is dialed in and the rest is easy!

What’s the length on the bigger one? Mine came out to +55"

Craig, are you sure you are not a bot? Can you prove it?

The reason I asked is that you learned the Einstar software ‘in an hour.’ It took me an hour to get one of my smart plugs to connect to my Wi-Fi!

I watched 3 or 4 videos then my friend scanned a fish. I just fired up exscan and went for it. My scan was ‘good enough’, not having undo sucks though. Had to restart a couple times. My lighting was great which helped.

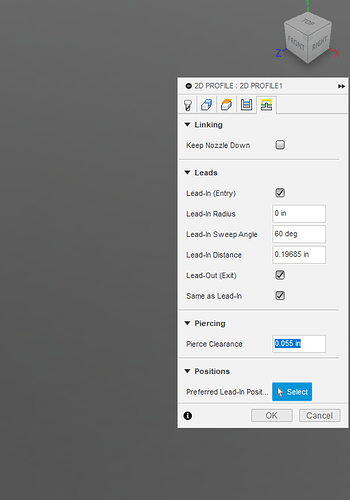

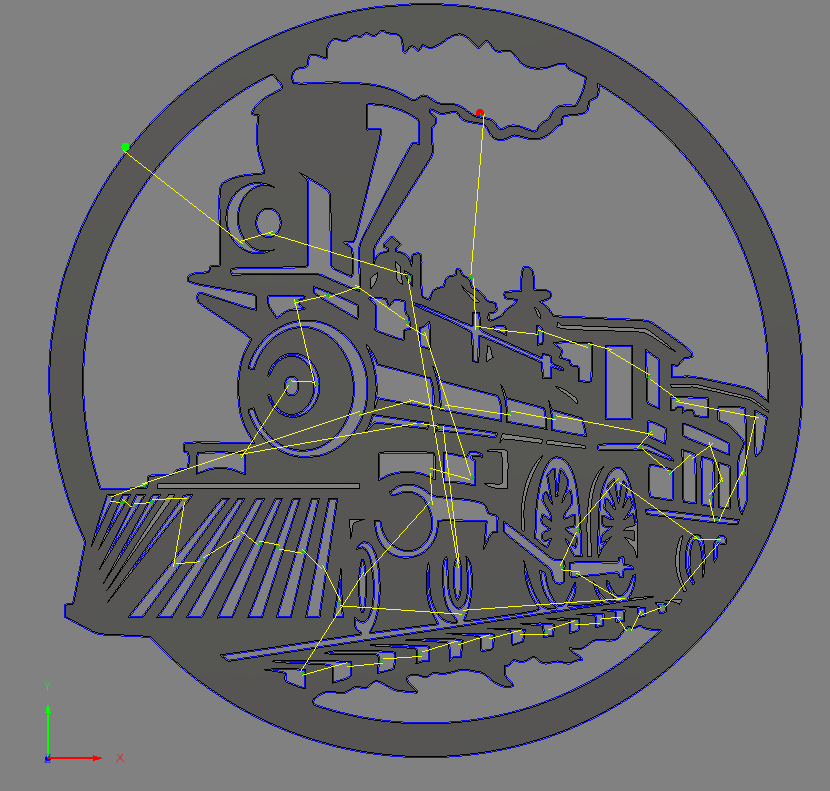

My youngest son’s birthday is tomorrow and he absolutely loves trains. Cut this guy out of some .040 6061 I had. Turned out ok. Some lines didn’t generate due to toolpath constraints which kinda sucks but he’ll be pretty happy. Next one will have a lower amperage and faster cut speed maybe. ![]() still trying to wrestle with F360. I’ve been using it for about a week now.

still trying to wrestle with F360. I’ve been using it for about a week now.

If you post your f3d file, one of us could take a look at your settings in “Manufacture” and give you some ideas. It would be a great way to learn for the next project.

For one of your first projects, it looks great.

Here it is. Thanks for showing me how to export it.

Htrain_alium v1.f3d (7.5 MB)

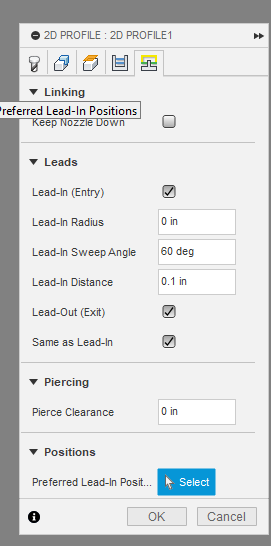

@not_neil_armstrong, I just made two changes. You never need pierce clearance and reduced your lead-in to 0.1 inches.

I tried to attach it back but it exceeded the 8 MB size. So just make those two changes on your end and see how it works

That’s awesome. I still have time to make him a better one with these little changes before his birthday tomorrow.

Thank you @ChelanJim

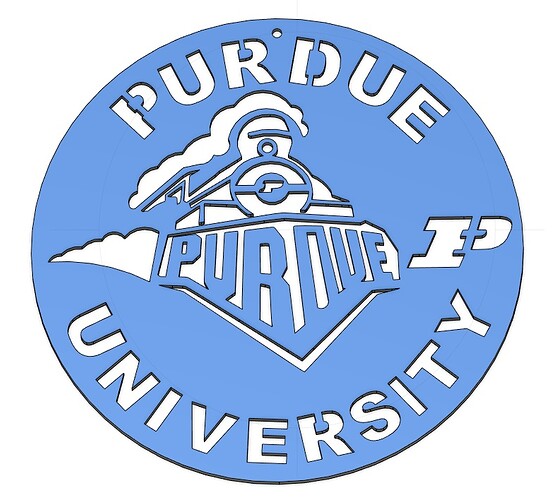

Is he by chance a Purdue fan? I made this sign last Summer.

I still have a couple versions on my garage wall.

This was the final version.

Purdue Sign.dxf (187.1 KB)

That’s a good-looking sign!

Finally got around to cutting it

Welded up

Cut, notched, and heat treated some 1/2" solid rod to act as a prop

I’ll cut it down some and weld it to a thick base to act as a nice foundation for whenever I want to display it

You should make some name plates of some sort to either weld on to them or use to make a base plate.