@Knick I made this my default setting for lead-in speed for 16ga steel. Anytime I cut new steel I get my IPM speed and set my lead in speed a little slower. Of course I save all these settings so next time I cut same thickness all I have to do is select it. So many people play around with this stuff and make it complicated. I should have a couple videos if interested how I do it. You can see it but I don’t have sound on my videos. Maybe this fall/winter when I do more cutting.

I added tip above on how I did the open cut and double clicked and makes it easy on open continuous line. Maybe this will help on future project.

I understand where to set it I was just wondering what was gained but setting lower. Do you feel your lead-in is cleaner/ better?

You never see my lead-in’s but something that made sense to me so have always done it.

These both cut good. i did a little rattle can paint job. Hard to see in pic but T-rex is shaded brown.

where are the pics of brisket?

I cut 16 gauge at 249 (what book setting is for quality cut) I have no dross. Hypertherm powermax 45 xp.

Sorry I should have stated why I run at 150ipm on my hypertherm. I normally use fine cut @ 40amps.

Ok.

My brisket smoked on my Reqtec 700 bull at 225 temp for 23 hours.

This smoker is over five years old now, not one issue with it. Use all through winters for cooking steaks sears them at 500. Bake bread in the dam thing as well.

yeah !! now we’re talking plasma fuel. I say that but we did salmon, chicken and some huge tuna steaks yesterday. normally red meat though…

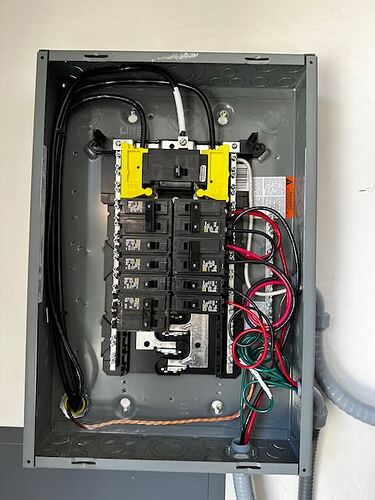

I got my Quincy Air Compressor successfully installed! With Timer switch, Auto drain, and Maintenance hour meter…

The auto drain is wired up through the switch so it will only turn on when the compressor has power.

I learned all of this here and on YT. This is my second large fixed air compressor install, ever. But this is by far the most complicated for me. I had to install a sub-panel to make room since my main is full and in the wrong location anyway. I did the math on average Amps used and so long as I don’t run everything all at once I’ll still be 80% of 200a on the main.

Nice job. Obviously you have done electrical work before… ![]()

if you look at the last pic, there is the Razorweld plasma 50amp plug and two dedicated 20a circuits, one of which is a single for the Crossfire controller. I guess now I should put my Crossfire together? ![]()

Actually, I need to run air lines, more circuits, lights, and finish moving stuff.

That is a great plan. I have mine hooked up the same way.

You’re definitely wise to get everything done before you slip off into the cutting abyss.

No that is just rust oleum flat black. Since it will be inside I figure that should be just fine.

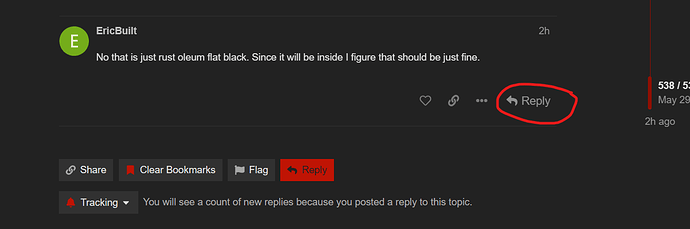

When you respond to a post that is a ways back in the thread, click on the reply button in that post. That way people can see what/who your responding too.

Here is where I clicked to respond directly to you

So this looks better in a picture or after a few drinks. I learned some things and the material was free. Just some time doing what I enjoy. The one I am making for myself will be a lot cleaner (I HOPE). I showed my boss and he wants it so I couldn’t say no. 18 Gage aluminum and 3/4 used plywood. I used spray adhesive to attach the flag to the burnt and varnished plywood. I am not to keen on the In it looks like an M