Are you using an airbrush for the shading? You did a nice job on the painting!

No, just spray balm. I get too much debris in them too. Lint, dust, and bugs this time of year.

If I decide to sell much of anything, I need to up my game on the painting process. This was kind of a one time thing for my neighbor who sells tie dye stuff at local craft fairs. She said my signs would really “energize” her booth. Also, she had me make the Grateful Dead stuff cause her crowd has it’s fair share of Deadheads.

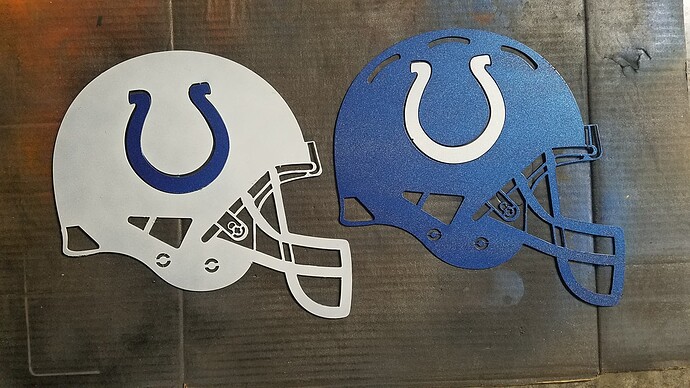

I’m still working on the design for some Indianapolis Colts signs(I live in Indiana). These are definitely not the final version.

I’m more here to brag that I cleaned my axial rails today. Used some cleaner I had on hand and got the gunk off. Been cutting (small scale) for about 6 months and never cleaned my railing or rollers.

nice! how many layers is that?

It’s just one layer at present. I will add a backing plate. I like to put the dropouts back in place like the ones a few posts up on the “Aces”. Its easy to paint them and just drop them back in their original position. If you add a back plate, the color of that plate shows through the kerf cut around the letters and makes a border. I like the effect.

I made a mistake on one section of the faceguard. Gotta fix that. Also still not happy with or without the vents near the top. I am thinking with vents, but making them a different shape.

Fabricated a 1/2 yard concrete bucket for a skid steer for a customer. Bucket is 64" wide and 20 3/8" tall. Nothing too crazy but was my first attempt at index cutting.

Man, that’s great work. What’s the function of the toothed bars across the top?

I am wanting to get up the motivation to make a grapple for my Kubota. That might require an index cut or two. Never tried it yet.

I have a 32hp and I have 14 acres, with about 5 acres being wooded. Always brush to move.

tooth bars = steps to keep from slipping

nice work

Thank you guys! @MartyY Nailed it. They are steps for climbing in and out of the cab on the skid steer. No other way to enter and concrete, water, and steel get slippery fast!

I designed and cut these over the last few evenings. Painted them this evening. I imported the wildcat head shape and the large IU symbol, but otherwise I drew most of the rest. The Indiana state image was imported, but was a disaster. Had to redraw most of it.

I live on the border of Indiana and Kentucky. The basketball rivalry is hot in this area.

Gotta fix the “R” on the next revision.

Designed this last night and just cut it. Only inserted the horse image.

It’s for a friend who built a 1984 Mustang, V-8 + turbo. He also sold some of my Grateful Dead things to co-workers of his. This is his commission check!

He plans to paint it a Ford maroon color.

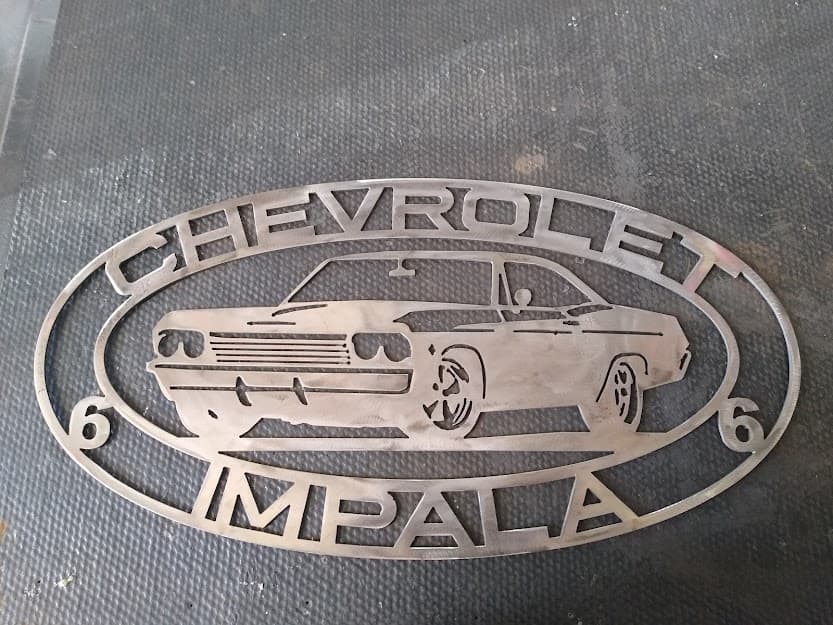

Man, I love those Impalas. One of my Dad’s friends bought a gold with black interior SS in 66 or 67. 4 speed with buckets. It was beautiful.

Edit: just look at some pics and it was a 1965.

First I need to give a shout out to @Phillipw for the torch height tap file and @ds690 for advice to others about setting the torch height in Fusion 360 to compensate for what FireControl and Fusion does. My cut height was at 0.095 even though it was set at 0.03 in CAM. Now I have it set at 0.022 and spring back is set to -0.02 with the result of a cut height of 0.059. Virtually no top dross and nary any bevel. So happy!

Here is what I did after figuring that out this morning:

- Napkin holder (modified from Fire Share

- Butterfly on trellis (my other project assigned by you know who!!!)

- Rocket Stove for Contest entry. Other pictures in the appropriate topic.

It was a long but productive day. I feel like I finally have my table back again.

Is that with a 40 or 60 amp tip and 16/18 gauge metal?

For 40 amp I have been setting cut height to .035 and spring back to 0.00, so I assume ( ![]() ) I am hitting about 0.05. The Cut60 cut chart is very generic and says 0.06 for a wide range of material thicknesses.

) I am hitting about 0.05. The Cut60 cut chart is very generic and says 0.06 for a wide range of material thicknesses.

Even though that seems to work pretty well for me(luck maybe), I need to do some investigating like you did.

I have the Hypertherm 45XP with the standard set-up for 45A cutting with the machine torch. I tested the settings with 16 gauge, 12 gauge and 1/4 mild steel. Each cut I verified by interrupting the cut to be sure that the torch was not getting varying cues from the torch height control. Laptop was running on battery. I checked once by plugging in without the ground plug leg and same results.

Here is that tap file that @Phillipw shared:

cut height test.tap (224 Bytes)

Just load into FireControl and it runs like it is going to cut but stops at what FireControl considers 0.060 Z height. Then you can measure. Obviously, it is not using THC so that is disabled in the tap file but it takes into consideration the IHS and spring back.

Edit: if you are not getting major hard dross and a bevel cut, I would not be concerned. You are probably pretty close. I was in serious trouble with the bevel so bad that it was noticeable with 16 gauge.

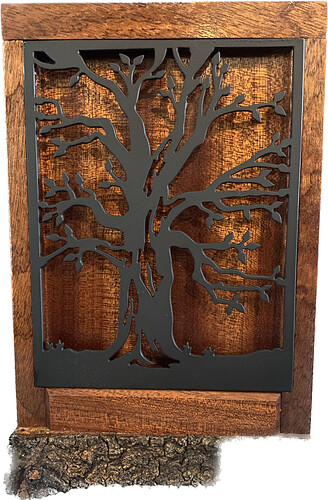

This is an URN I didn’t plan on making. The wood is sepele mahogany except the base which is live edge Florida water oak from a tree that my father in law cut down. He loved being in the woods and taking care of the land. Hence the plasma cut tree on the front. This is exactly the type of thing I was thinking of when I got my plasma table.

I started sub panel install today. it’s mounted and I poked a hole through the garage wall…