Did you do the heat coloring in a oven or torch?

I am definitely impressed with the detailed work you guys have posted. We have been using our Crossfire Pro for 2 years now and just changed over from a Miller Spectrum 2050 to a Hypertherm PowerMax 65. We use the machine torch with standard tips. Most of our work is 1/8" to 3/8" aluminum with some 16 to 22 gauge stainless in the mix. The machine has more than paid for itself and we will continue to use it on custom in-house projects. If you want to see what we use the parts in check us out at www.evi-fl.com.

Just put together a sign I made for local baseball team. I believe they plan on hanging on dugout at games. The paint can is for scale…30’x30"

That is a very very cool sign @DonP

Shoelace idea is one I have been saving for a while now. Anything to get away from the normal 2D sign.

![]()

That is awesome! You need to start a sign art gallery.

Hi all,

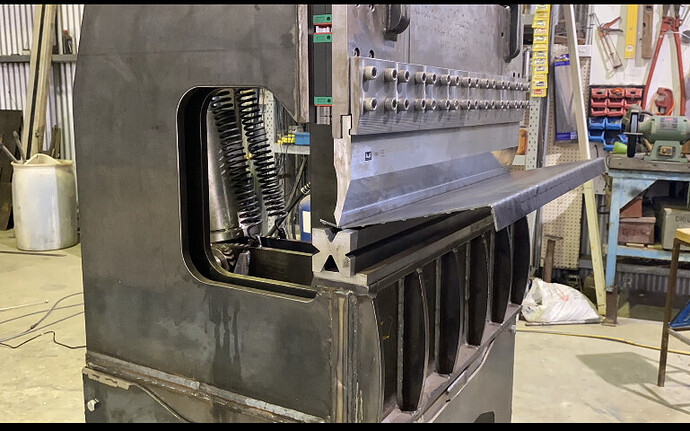

not necessarily done today but still a work in progress, I am building a brake press and my crossfire pro has played a major part in building it. Mostly made from 16mm mild steel which was cut with a Powermax 45. The manual/pneumatic hydraulic ram should give around 100 metric tonnes of force on the blade with a bending width of 800mm

Map gas with plumbers torch

That is sweet! Some more pics if you don’t mind.

Do you have the dxf file for the for your lead screw covers?

That is impressive!! Thanks for posting

I purchased a cheap harbor fright 36" bender which works most of the time for 16ga and thinner metal but wish i had one like this style of brake with fingers. I have seen people doing this type of modification with the hydraulic press at harbor freight and really cool!

MechanicJon, I do have the DXF for the covers. However the forum would not let me attach the file since I am new to the site. If you email me at jeff@evi-fl.com I can send the file to you.

Hey Jeff, if you’re willing to share, you could post it over on the Fireshare site. Link is at the top of this page.

Very good, that’s where I actually found the pattern 2 years ago. Just search for “lead screw” and you’ll find the file posted by Michael.

I did that myself. I got the HF air-compressor version of their 20 ton bottle jack to provide the pressing force. It’s quicker than the standard lever action bottle jack the press comes with. Then went to SWAG Offroad to get their finger brakes - both the standard and their gooseneck dies. Works great! Highly recommended.

Yes. I believe it was you that planted that thought in my head. But my pocket book resisted the gooseneck dies.

![]() I added them after the fact. Upfront they seemed like a lot of money.

I added them after the fact. Upfront they seemed like a lot of money.

Now if I had an MR-1 I could have made a set reasonably inexpensively ![]()

WARNING…PUT YOUR COFFEE DOWN BEFORE READING SIGN!

I was smoking a pork tenderloin last night to get ready for MSU game today and figured i needed another patio sign. I just cut this morning and still have to paint later today. I’ll post file to fileshare in few hours without the letters…lol

You could make with stainless for real BBQ tray if someone wanted.

Looks good. And I’ll admit I nearly spit my breakfast all over my computer when I read what it said! ![]()