Its always out of the blue. It has happened to me.

Fired it up today cause I’ll be cutting 3/8" aluminum for the first time ever.

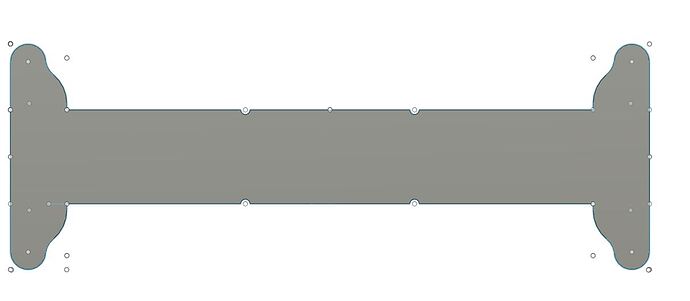

The gasket you guys see there is just the template.

Did it for mock up purposes.

Hopefully I don’t kill this aluminum in the next day or two when I cut it.

Yeah that was just so freaking odd.

I do understand the issues that plague some Ryzen U users, but I was left unscathed for some years ![]()

60 amps, 1.2 pd, 23 ipm. I cut it all day. Now, that an Everlast.

Yeah some of you cut aluminum often. I don’t due to no requests.

I can follow book settings for my Hypertherm, but do wonder if there’s anything else to be watchful outside of dross catching the nozzle.

I just put the nozzle jell on the cup. I use nitrogen, but air works great, too.

Man, yeah I can’t pull that off.

It’s a one time order and I’ve got no desire to spend money on nitrogen.

Air will have to do!

Also wondering if installing a new version of FC is fucking with my cuts.

The 10 gauge I ran just looked like shit.

Disregard, no worries.

It’s fine, new FC version was just throwing me off since the default value for override shows .04

Hello, I apologize for however long it has been since you made this post. I just saw a notification about it today. What setting are you interested in specifically?

No worries! It hasn’t been that long… You have the same Everlast machine and Crossfire Pro table and you have beautiful detailed cuts, so I know it is possible! I was just curious what basic settings you use-- tips, speeds, etc. in general. I was having trouble with weird cuts but I think it was that my air wasn’t dry enough and we have fixed that problem (hopefully). So now I am on to settings to get things dialed in…

Well this may be a small feat for some but if all goes well it will be only my second paying job. Its been almost two years of owning my Pro, I am staring to justify the purchase. ![]() I need to make 10 more. Its part of an adjustment tool to align solar panels. Any suggestions on bending them with more accuracy without buying a Titan? I am currently using an Ironworker.

I need to make 10 more. Its part of an adjustment tool to align solar panels. Any suggestions on bending them with more accuracy without buying a Titan? I am currently using an Ironworker.

Only 10? Make a template and rinse & repeat.

ACFrOgBiZgGnIZ_faY61udw-c58QsbPreCBsXLA_OYF1ihr_DCGwP0F1nNeWtQxbT3qOFse26mG6UB9i7AdWW56CarYnZXREt_IM6CALWPZDdnM43xHNu8SpANBgov0= (3).pdf|attachment (48.0 KB)

These settings work very well for me. Any information you need, ask. Just disregard the second column on the 1/2 plate. I just haven’t gotten around to deleting it.

Don’t know what an ironworker is…I was under the impression that was a profession?

I like using a small press brake for precise bending. A backstop comes in handy for just tossing it in and hitting the foot pedal.

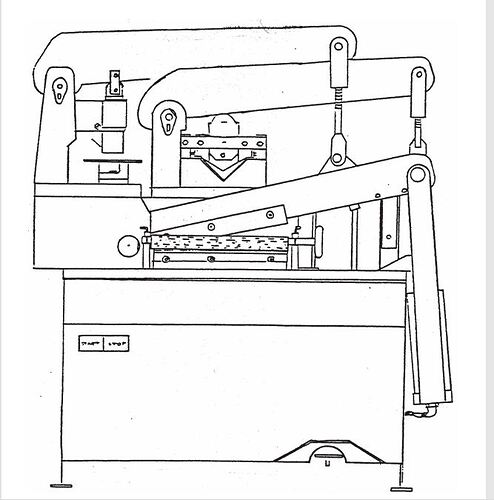

A fairly common piece of equipment in most industrial metalworking shops.

I happen to have an old Scotchman in my shop. Mine’s a lot more beat up than this.

Some of them like mine will have a little brake that’s one of the options.

Edit.

Here’s some picture of my old girl.

On casters and comes out when she’s needed

Yep that is it. model 314 mine is also pretty beat up I have made a lot of railings with mine. I use the punch more than anything. Here is a pic from the original owners manual. its an old machine but still works great.

I see, I’ve always known it as the profession itself…then again I know too many in unions ![]()

If it has a brake attachment, I can’t see how “more accuracy” is needed? Just the right punch and die!

I have an old manual for mine as well.

Shocked look:

And every other manual known to man! I think Jimmy captured the Universal reaction to that statement!