-

Definitely you’ll want to set your setback according to the manual and the clamping pressure is also important which should be listed in your manual.

-

3.This is exactly the right question to be asking with a leaf break. On thinner material I do try to line up with the center line but depending on which part of the material is inside or outside of the break it’s going to bend that line slightly different. A leaf brake is not a press brake which is what all these bending allowances charts are designed for. A piece of metal does not deform the same way in a leaf brake as it does in a press brake.

When bending a pan uniformly on a leaf brake using the same line to break from you would either have to go around the whole pan and break all the flanges facing into the brake or brake the whole pan with the flanges facing out of the brake to have a result that’s uniform. If you’ve been some of the flanges with the body inside the brake and some of the flanges with the body outside of the brake the flanges would not come out to the same height.

- Again while you can get a bend allowance from a leaf brake it deforms the metal not uniformly like a press brake does. Cut a 4 inch long piece of metal bend it right at the 2 inch mark and then measure how long the flanges are. Once you know the flange length you’ll know how much material you gained when the metal stretched during braking.

The math for figuring out the k factor using the material difference while it bend test.

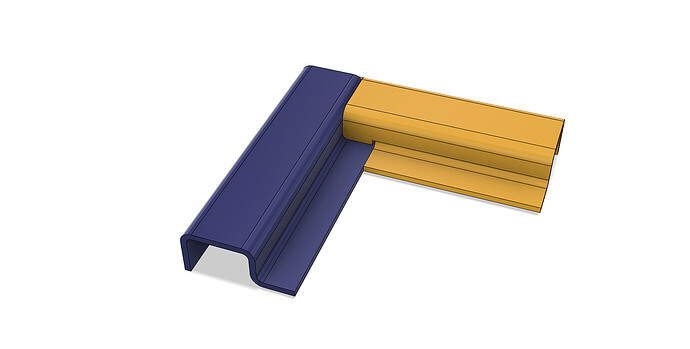

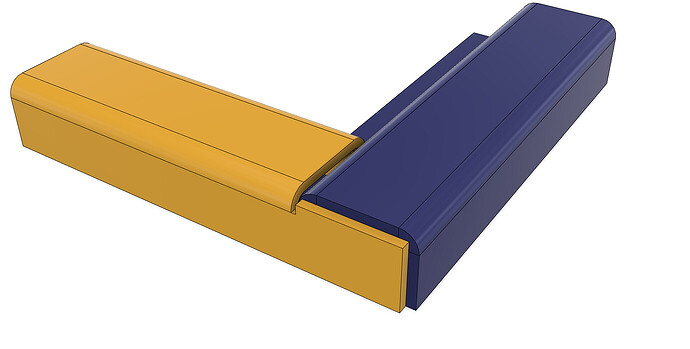

This project I did I really had to be careful about not only my Bend order but which piece is inside or outside of the brake during the bend.

@holla2040 that product design online video you linked is really good. Product design online is probably one of the best resources for learning Fusion 360.

Here’s a sound effects pedal enclosure I made it very similar to the project in the video. About 600 posts up from here.