Some people use those foldable funnels cut and mounted upside down. I didn’t have much success mounting the ones I bought - they were too cheap and fell apart.

Have you seen the shield on FireShare?

https://www.langmuirsystems.com/fireshare/torch-water-shield

Thinking I’ll just 3D print something when I’m all setup

here is something…how full do you keep your fluid…in other words…how close to the metal is the liquid?

The water level is approximately 3/4 of an inch from the top of the water pan. I have tried lower and it doesn’t matter. On this project i am cutting, you have to get as close to the limits of the table so the last 32 inches of the 4x8 sheet doesnt get wasted.

I’ve been thinking of making a removable shield out of some 26ga sheet. Something that will slip fit on the edge of the water table and extends the lip 4-6 inches or so and deflects the water back into the table. Idea would be to put it in place before starting the cut and take them out or move them as the cut progresses. I haven’t experienced as much water loss as you’re describing - I’ve mostly been able to keep away from the edges, but I’ve had a few cuts that I needed a mop after.

Since you have had to use the mop then you know what i am talking about…lol.

I think you’re just not moving the torch fast enough!

JK…

Actually, now that I have a working Z axis, getting the torch up in the air ASAP once the cut is made has been the best solution. The extra ‘blowing’ by PC to cool the tip is what’s really blowing water all over the place. I’ve reworked my Post Processor so it literally pulls the torch away once the cut is done.

I have a scrap piece of 18 gauge about 4”x6” that I slip under the torch to block the post flow from splashing water everywhere.

I need to learn how to mod the post processor for fire control to do that.

Looking at the FireControl 1.5 sheetcam post processor it already raises the Z 1 inch after a cut (if you have both Pierce and Cut heights set to non-zero values). Note that it does this AFTER the end of cut delay.

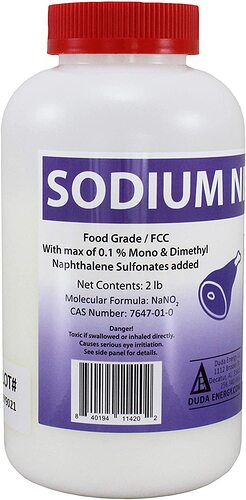

sorry for more questions about this…i have looked at Amazon for the Nitrite…they have 2lb food grade (pic) for $21.18 and

which says used in manufacturing…but then there is a 4oz fine granular one for $19…I’m not being picky about price, but wonder if the 4oz one is not like the other…also found a bagged one pound says Chemically pure for $16.99 …so the “type” is what i am making sure with you on what i need. nothing on amazon says Anti-rust additive…thank you in advance!

nothing on amazon says Anti-rust additive…thank you in advance!

You want to get reagent grade, pure Sodium Nitrite, with no additives and, if you’re going to get more than 4 ounces, get it in a container that’s resealable because that’s all you’ll use for a long while.

I got this one as well. I like that it said “Food Grade” made importation so much easier! ![]()

At first they sent the wrong thing (Potassium Hydroxide). Paid a lot to clear it and dispose of it and it gave the lady a bad skin rash, when messing with it, necessitating a trip to the ER.

thank for the heads up…I checked we got the Food Grade…wowl….don’t need a trip to the ER at this point…

I make a ton of sausage, smoked fish and jerky so i always have a bag of pink curing salts on hand. But ive only used borax in my table water. Ive tried different things but it always turns to a red rusty mess no matter.

So, does the Borax work well?

Did you test the pH?

No, i havent rested it. My water is already between 7 and 8 from the well.