Yes it is. And I have 36.3-36.6 volts going in. So you’re wondering if there could be a voltage drop in the post power supply voltage? Ok, that makes sense to check.

Send me the control box… If it does not work on my table, we will have a direction to move forward. All we are doing is spinning our wheels. The Everlast puts out almost no EMI.

There is a ground stud on the back of the plasma cutter that when hooked to earth ground makes a faraday shield around all the internals.

#1 I have seen different continuity readings from putting water in the table… Not sure if the torch firing would make any difference continuity-wise but you could also try to measure voltage.

#3 If the voltage drop (under load) is not a problem it would seem like your connections are good. We’ve all seen those connections someone else put together that were not great, meaning not fully seated copper strands outside of the pitch connector etc. Just really checking a box on this one.

#4 you can still fire that torch manually by shorting the pins of the torch on/off barrel connector. You could put a switch on that pretty easily.

Ok, @ScottNH, @Wsidr1, @ChelanJim, @MechanicJon, @Bigdaddy2166…

So I tried just about everything suggested included isolating that one receptacle, moving the plasma cutter away from the wall, rerouting cables, etc, etc. Nothing seemed to make a significant difference.

AND THEN

I tried isolating the workpiece from the table slats. That didn’t make a difference either, but then I realized my ground clamp was still contacting the edge of the water table so I isolated that too AND I MADE A CUT WITHOUT ANYTHING FREEZING!!!

So what does that mean? It’s a ground loop thing, right? Obviously I can’t use the table this way. So what do I do?

Unbolt your control box from the table and try again… Just set it on the floor

Setting the workpiece on the slats as normal (NOT isolated)?

Disconnect the control box housing from the table leg. Try again. Run a cut as normal and then like you did before.

Fantastic! Progress! I would say it is a groundloop thing. As John says disconnect the box from the table and see what happens. You’re on the road I hope!

Now I’m wondering where the connection is there has to be a bare wire or a pinched one or something like that.

Hopefully it works. Get you some of these from McMaster Carr

Isolation Mounts, with Stud, Natural Rubber, 1/4"-20 Thread, 50 lb., 1/2" High

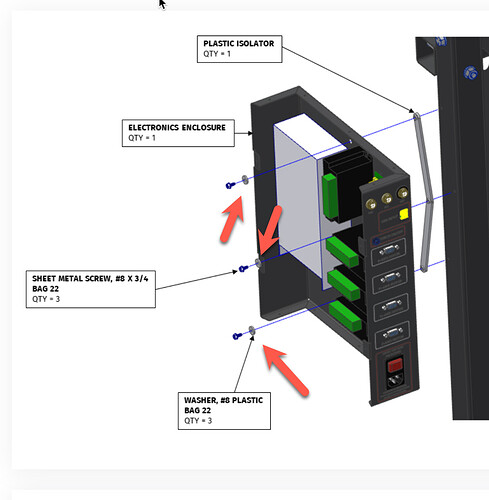

Casey I know you’ve been very thorough but when you pull that control box off of the leg make sure these plastic washers are in there. As you know it’s what isolates the control box from the table frame electrically.

Ok.

Yes, @ScottNH, plastic washers were in place. I looked closely at every wire inside the box and nothing appears damaged.

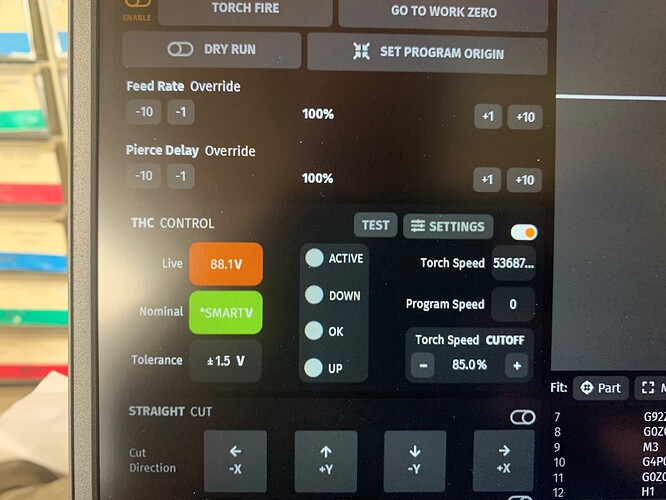

Removing the box from the table chassis had zero effect on the freezing issue. I performed 5 cuts; FireControl froze instantly each time. One time it froze with torch speed registering “53687…” but I do not believe the torch was actually traveling quite that fast. ![]() I also had a “torch moving before cutting voltage sensed” error, while the machine was cutting normally.

I also had a “torch moving before cutting voltage sensed” error, while the machine was cutting normally.

So, I re-isolated the work piece and clamp as before and performed two successful cuts, back to back.

So, the voltage is not entering the electronics via the table chassis. That leaves the limit switches, the motors, and the IHS wires, correct? I’ll start with the limit switches since they’re the easiest to disconnect.

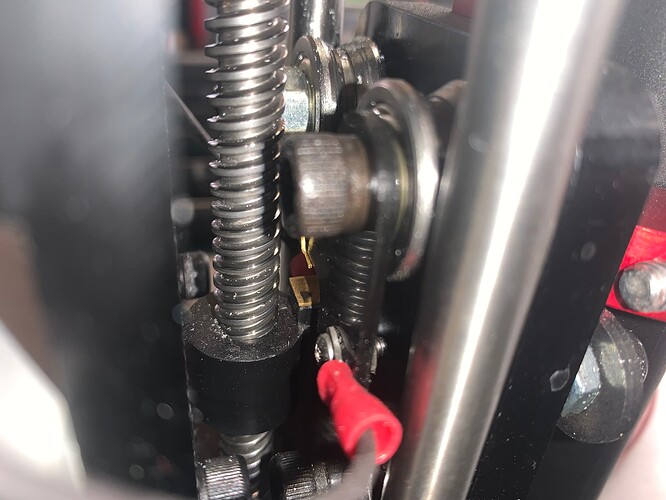

Ok. So, the voltage appears to be back feeding through the IHS. I have checked this, and cleaned the IHS contacts multiple times, in the last 30 days, with no effect to the freezing problem, and the IHS functions normally, but since installing the Everlast I notice I have some nice scorch marks on the IHS contacts that weren’t there before.

I’m a little bit confused about what this means, and how to fix it.

When you raise and lower the z axis by hand physically, does the IHS light come on in fire control?

If you look for continuity between the table frame and each of the IHS leads is there any? Seems like something in that circuit is grounding out to the table.

I agree with Scott. Thats just a simple on off switch. Following the cable back to the control box and inspect.

Alright, @ScottNH & @Bigdaddy2166.

It’s not the IHS; it’s the Z-Axis motor.

I had unplugged both, because I was thinking that with IHS unplugged the Z-axis might do something weird.

After checking for continuity and inspecting the IHS cabling, I plugged IHS back in, leaving the Z-axis unplugged, and it’s still cutting normally.

I’m sorry for the confusion.

What is confusing to me, is that I have had FireControl freeze with the Z-axis motor unplugged in the past, while performing nominal voltage tests on various material. But that was so many iterations ago, I kind of have to throw that away, at this point.

Obviously, the Z-axis motor back-feeding voltage is a little bit harder to diagnose, right?

Wonder if it could be a feedback through stepper motors. When cutter chassis is part of the system it freezes. You could try unplugging the x axis motors and make a y axis straight cut. Then do the same for the y axis and make an x axis cut.

Reading my mind you crazy one.?

That came to me as an assembly I think? I’m not sure if there was any motor isolation effort or not. If there isn’t then it would seem like there is a short in the motor circuit somewhere. I wonder if this is something @langmuir-aksel has seen before?

I have a spare motor in my parts box.

I could send it to you tomorrow if you like.