No telling who is buried around Reno… ![]()

You can go into the settings and just tell FC that you don’t have limit switches and it will not look for them. If you wanted, but we both know it is probably a fools errand. HA! I finally found a good use for the phrase.

John, I know you’ve seen Bonanza. I’m basically in Virgina City; just at the bottom of the canyon that runs through the middle of it. I’m sure there’s all kinds of bodies buried around here. I’m less sure about their effects on EMI. ![]()

Aren’t you right on top of the mother load!!

I’m sure there are lots of skeletons(both literal and figurative) down in that mine. I remember visiting Virginia city as a kid. Felt like the place was haunted!! ![]()

![]()

You could just downgrade to win10 as I described earlier and still be able to run the latest firecontrol once you know 20.6 (or 20.5 as I do) runs good or not.

I prefer win10 or over 11 anyways.

Plus when you downgrade, it wipes the drive completely and only loads a clean win10 without all that bloatware you get when you buy a new computer.

I was really hoping you’d be on a cutting binge tonight. Damn.

Can I throw out something crazy, Casey (see what I did there?)? Is it possible something about the physical (not wiring) configuration of your garage is causing the EMI to be amplified/trapped/echoed/enhanced,… whatever the correct electrical nerd term might be? Have you thought about or is it possible to roll the unit outside, or at least into the doorway? Can you get the controller to a different area? Any kind of reconfiguration that might better isolate the controller.

I know that sounds strange but your reply says you feel EMI is the root cause of the problems.

Anyway, again bummer and I hope Langmuir steps up. If I owned the company, I’d have someone at your house because there is definitely something to be learned here with all that you have tried.

Really is fascinating history where you live. I went back a couple years ago when I could appreciate it. Really enjoyed learning more about it.

I hope that some of the GREAT MINDS in this group will read this post, because I’m well past the limits of my own understanding.

The reason I think my problems are EMI and not software, but likely exacerbated by the software or Langmuir’s hardware (electronics enclosure):

When I tested the Primeweld with torch and work clamp leads connected, it froze FireControl literally as soon as the arc would strike, and it did it every single time I attempted a cut. I ran probably 10 cuts in a row and it froze every time the arc would strike. That’s been the most clear manifestation of the freezing issue that I have seen, and the worst performance I had documented to that point.

Connecting the work clamp lead to the torch lead had the potential for the EMI to either be lessened or amplified (or possibly to have had no effect at all). The science behind this is a bit inconclusive, but it seems it comes down to the direction that the conductors in the individual cables are wound. Regardless, no other changes were made, and my problem, which has been fairly consistent, manifested itself in the worst way it had, at that time.

The work clamp lead on the Everlast is very thinly insulated. It stands to reason that it could put out even more EMI than the Primeweld work clamp lead.

The Everlast is behaving exactly the way the Primeweld was when the work cables were connected together. And that is the only other time the plasma table assembly has behaved this badly.

The reason I think the problem is being exacerbated by Langmuir’s hardware or software is because, so far as I can tell, no other Langmuir user that this group knows of collectively has ever had EMI so bad that FireControl froze EVERY SINGLE TIME the plasma arc strikes; or at least not without some seriously obvious problems that I have already addressed. And while the EMI has been less of an issue at times, for me, than it is right now, it has been consistently bad, despite many best practice attempts to fix it.

Regarding the environment I am using the equipment in; yes, I can’t rule it out. I’m sure some of you have noticed that the plasma table is on a wall that is made of corrugated metal. That fact has crossed my mind a few times, but common thinking is that metal roofs will block radio frequencies, not amplify them. No cabling touches the wall. I suppose I should try to get the table further away from the wall to make a vague attempt at testing this out, but I’m failing to wrap my head around how it could have a negative effect. Metal cages tend to block radio waves, which is one of the reasons Langmuir suspects everything else before their own electronics enclosure.

And no, I can’t really test the “environment” beyond that. At least not easily. I don’t have 220 close enough to the door to get the table outside, or even into the doorway. I have a 220 extension cord, but it’s still probably 10’ shy of being long enough.

Regarding FCv20.6; as Langmuir has told me repeatedly, almost every table they’ve sold in the last year or more is running FCv21.1, and nobody is having the problems I’m having. I’m sure it’s something to try, but they don’t really see any point in testing it, and it’s not “easy”, so it just seems a little bit like wasted effort (at this point).

The thing is, I could probably keep coming up with “things to try” for the next couple of months. As it is, I’ve spent about 40 days trying “things”, and I literally can’t cut a 1” line on 22ga at this point without FireControl freezing, and then crashing.

I’ve purchased two different plasma cutters and two different laptops; that’s about $2,700 on top of what the table cost. I think it’s fair to call this “due diligence” trying to trouble shoot the parts of the equation that fall under my own responsibility.

I say that, because I think I’m at a point where Langmuir needs to start coming up with some ideas. There has to be a way to test that electronics enclosure out, perhaps, without them having to send me a new one. Or perhaps they could send me a “known good” used one to try.

I don’t know. Their table isn’t working, and I’ve put in a Hell of an effort to test out the possible causes.

Yes it is. It’s a big part of why we fell in love with it. If you come out here again, you’ll have to look me up.

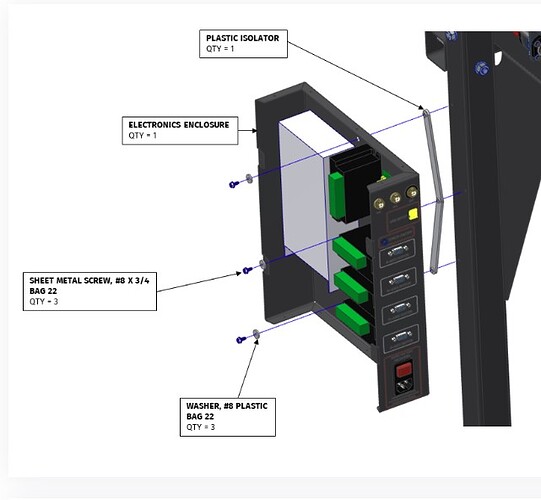

You do have the plastic spacers on the controller box correct?

You might try unscrewing control box from frame and trying it.

That should have shown up with the continuity testing that he did…but you’re right, it is always a good thing to check to make sure there is still that isolation.

Is it possible that the THC module can be attached wrong in controller? I don’t have THC on my pro and my XR it is already installed. Thought I would throw that possibility out there.

I’m also curious what the power supply voltage is putting out while it’s running a file. Only way to test that is hook up to output wires with cover off and run it.

While following this thread, I notice that my USB port was mis-aligned and touching the case. I had to disconnect the connectors in order to reposition the board. The connector shapes do NOT prevent them from being installed incorrectly. There are some abbreviated labels that can be used to confirm where the plugs go, but it is possible to do it wrong.

That means the waves don’t pass through, which means the ones striking your metal wall would be trapped and reflected.

Just a thought. I don’t have enough knowledge on the subject to do more than just throw it out as another possible reason.

Again, I feel you’ve done more than your fair share here. I believe Langmuir owes you more assistance.

Casey you have done a lot of work here and I am shocked (no pun intended) this hasn’t been resolved yet. With that said I wonder about a couple of things. I have tried to follow the thread but it’s now a full time job so I apologize if you’ve already addressed these.

1 no continuity between table and USB cable (both static and when you try to fire it).

2 no continuity between your metal wall and the the USB cable. I’m thinking about it as an antenna rather than a shield. I’m wondering if somehow and metal outlet box or cover is contacting it and transmitting collected EMI to your ground.

3 are we absolutely positive about the quality of the connections in your 220v supply outlet and at the panel for the Plasma cutter?

4 Would it be possible to set up a test where you run the table in a dry run mode and hand fire the torch both with work on the table and off of the table to see if it’s EMI running through the frame of the table or through the air. When I say hand fire I mean literally with the trigger on the hand torch not manually via software.

5 Last could you electrically isolate the work piece from the table by putting it on wood blocks or something. Similar to previous question but might be easier to start with.

I’m trying to figure out ways to isolate where the stray voltage is coming from.

Sorry if this was crazy or repetitive.

@MechanicJon @ChelanJim @rat196426 @Wsidr1 I’m replying to you all together. Hopefully I’ll catch all the points you made. You guys are thinking outside the box and I like it.

#1) Jon, and Jim, I’ve got the plastic isolator between the Langmuir box and the table, and I have done continuity tests like crazy. My ohm test infinite voltage to the table slats with infinite resistance (table on) means I have perfect insulation between the Langmuir electronics and the table (according to LS).

#2) Richard, as often as you see people stacking their spare sheetmetal next to their table, I agree that the wall acting as an antenna seems unlikely, though I’ve been thinking I can relatively easily pull the table and plasma a couple feet from the wall and see if it has any effect.

#3) Richard, I triple checked the installation on the THC module. It’s as per instructions.

#4) Jon, I have checked the power supply voltage, but not while running a file. Can you elaborate more on what you’re thinking?

#5) Bret, I labeled everything and took pictures when I spaced my USB out, so I’m confident I got it back together correctly, but I agree that could bite someone not paying attention. Regarding the wall acting as an antenna, I’m going to try moving the table today to see if that has an effect.

To test the power supply output you’d have to attach wires to the screw binding terminals of the power supply then attach your multimeter to those wires set on DC voltage with alligator clips. Then monitor voltage while running a cut. Also is the 120v 220v switch is in the correct position in control box power supply?

Not at all. There are some great ideas in here. Let me try to address them.

#1) I have not probed USB to table continuity with the arc on. Will EMI show up as continuity without a physical circuit? I have zero continuity in any other scenario.

#2) You may be on to something here. All of my 110v outlet boxes are plastic, which is probably a code violation with a metal wall, but I do have metal outlet box covers, and there is one that barely contacts the flashing on the metal wall. It’s not the one the table electronics connect to, but I do believe that could be a potential bridge to the circuit ground. That said, with a ground plug isolator on the Langmuir electronics, I still have the issue. Still, taking that cover off is going to be the first thing I try today.

#3) I have acceptable voltage, acceptable voltage drop, and it is wired correctly. I’m not sure how to determine “quality” beyond that. Can you elaborate?

#4) No, because I no longer have a hand torch. BUT, I have noticed that the THC test seems to complete successfully. I can try manually firing the torch (software), Z-axis as high up as I can get it. And I can try to do this with the work isolated as you suggest in #5. INTERESTING idea. I will report back.