Hello,

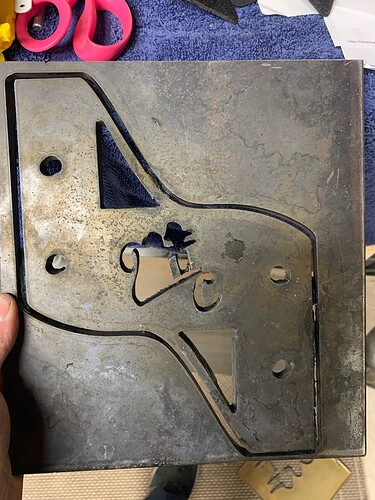

I just attempted my second cut(s) on some 3/8” plate on my newly assembled Crossfire Pro, running Primeweld’s Cut60 plasma cutter and their machine torch. I only had one piece of metal, so I would tweak settings and repeat the cut, and I did this a few times, and never really got through the 3/8” plate cleanly all the way around. I’m not sure how much help my pictures are going to be, given that I took multiple whacks at it with different settings, but I’ll do my best to explain my process, and hopefully I can get some recommendations on where to start improving.

My air system is a 5hp (overrated) 60 gallon upright compressor, into a 40 micron pre-filter, followed by 50’ of 3/4” max air line, into a 3 stage Motorguard progressive coalescing filter/desiccant dryer combination. I have no discernible moisture. I also live in the desert, so it’s pretty dry to start with.

1st cut settings:

1.5 second pierce delay

0.150” pierce height

0.060” cut height

40 IPM

53 Amps

70 Psi

Ground connected to table drain but (per Langmuir’s recommendation)

1st cut was really clean in a couple of spots, and didn’t cut through at all in several others. Holes appeared somewhat tapered.

2nd cut settings:

Dropped feed rate to 37 IPM

Bumped amps to 55

Bumped air to 75 psi

2nd cut wasn’t really any better than the first. Checked consumables after (were new prior to the first cut) and they were toast, so I replaced them. I also tightened the coupler on my z-axis, which I suspect was slipping.

3rd cut settings:

2.0 second pierce delay

0.150” pierce height

0.060” cut height

35 IPM

55 Amps

75 Psi

Ground still connected to drain nut

3rd cut results finally started to work at the area’s on the perimeter that didn’t seem like they were cutting at all the first two times, but still didn’t get through them.

4th cut settings:

Moved ground to work piece, just ran perimeter. Still didn’t get all the way through. Gave up. Checked second set of consumables and they were toast now too.

Anybody have any thoughts? I hope to work a LOT in 3/8” steel with this machine, so I hope it’s going to be up to the task, but the learning curve is looking like it’s going to be darn expensive.