It was a very A/B testing situation with the leads tied together and then separated, and it surprised me too, @DnKFab. USB cable is Langmuir factory version, and it has ferrite at both ends.

Have you messed with the USB? Try the paper trick. It takes a second. Also I would wire to raw voltage. I did notice with mine, run the air switch on the plasma cutter and watch the live voltage. When I was wired through the CNC port, I would get 12-13 volts, with just AIR coming out the torch. Thats what made me wire to RAW. Since I did raw voltage and the usb trick, its been flawless. I cut all day today and it cut perfect!!!

+1 I would absolutely be running raw voltage with the primeweld if that hasn’t already been done.

@AVRCUSTOMS did you start running yours with Raw voltage? On your post you’re having trouble with the picture in the your other topic of your prime weld shows it being hooked up with divided voltage are you still running it that way?

I’m sure I’ll get there eventually, @TinWhisperer. I’m trying to change one thing at a time, and then test.

And I’m admittedly doing a poor job of that, but I’m at least trying to limit MAJOR changes to one thing at a time.

I’m just sort of awestruck that I started out able to get through almost an entire 4x2 sheet with 100’s of pierces and G3 curves, and now I can’t cut a 10” straight line cut without FC freezing.

It’s almost like something in the system is gradually failing, and it just keeps getting worse the longer I run the machine.

And I guess that the “something” could be the voltage divider, but I’ve run the setup utility multiple times, and it seems to be behaving normally. And LIVE VOLTAGE readings in FireControl are ALWAYS in the expected range right before they freeze.

Anyway, it’s certainly worth a try, I guess, and I’ll probably slot switching to raw voltage for right after I try and test moving the USB port.

But I think there’s something else going on, because I have a hard time believing that straightening cables out made things worse. And I have a hard time believing that having everything off in the house made things worse. And It’s even a stretch that those DC cables are bad, but even when I moved the plasma back where I had it previously it still froze each time I tried to make a cut.

Haha! I’m following everyone’s advice and it’s getting worse! ![]()

I would forget all the other avenues right now and 100% switch over to Raw voltage as your next move.

While the voltage dividing issue has supposedly been fixed in the new machines, historically it was a real headache.

Respectfully, @TinWhisperer, I’m going to do the USB first, because I told Langmuir support that I would address that next.

If that doesn’t work, I’ll do the switch to raw voltage after that.

The only reason I questioned your advice in my last post was because Langmuir support said that they were satisfied that my voltage divider and VIM were functioning properly after THEY went through the setup procedure on my laptop.

And both Langmuir and Primeweld customer support have said NOT to switch to raw voltage; Langmuir, I’d guess, because it introduces another variable, and Primeweld, probably out of hubris.

I get that there are people on this forum that may actually know more than the manufacturers of these products, but at the end of the day, the manufacturers are the ones who will replace broken parts under warranty, so I’m trying to thread that needle as deftly as possible.

I was wired to divided until I noticed I was getting 12-13 live volts in fire control with just air coming through the torch. I wired to raw and fixed the usb and all my issues went away!

I thought mine was doing that too, @AVRCUSTOMS, because I heard the air and I’d see ~20 volts, but I looked and I had little craters in the metal from the arc trying to fire.

so we don t know it the swap to raw or the usb was the fix then?

they were “fixed” at the same time??

If I was @langmuir-reilly I’d consider re removing Primeweld from the plasma from the compatibility list when being using with divided voltage.

I did them separate. First raw voltage. That fixed the voltage without the torch running but thc still did not function. Fixed the usb and thc works like a champ

Well that’s a good piece of information.

Did you have continuity between the langmuir electronics enclosure and the frame of your machine?

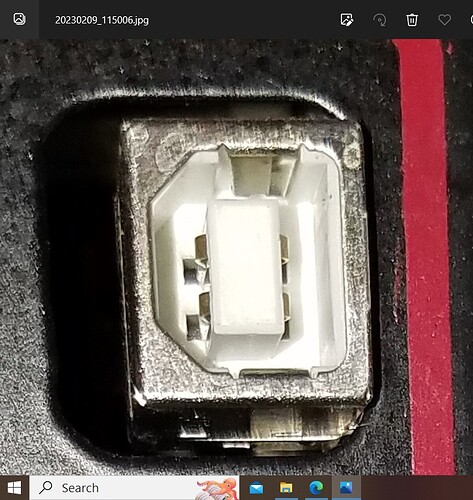

I’ve seen the pictures where the USB is touching the sheet metal enclosure I’m wondering how that would have closed a loop though if electronics enclosure was isolated?

So the raw voltage is a bit of a red herring here ? you’re saying it did not contribute to solving your issue ultimately?

+1 on changing to RAW voltage. Make sure when you do you hookup to the raw voltage inside the machine. Not at the CNC plug raw voltage. I would just do it now because it’s something you should do anyway whether it’s causing the problem or not. I certainly respect and appreciate your approach of one thing at a time… but it’s the easiest thing on the list and as I said it’s something that needs to be done whether it’s what’s causing the problem or not. If you read the Primeweld PSA from Langmuir(search the forum) you will see that several Primeweld users started experiencing issues with the voltage divider after making several successful cuts. After reading that I swapped mine even though at the time I wasn’t experiencing any problems.

Really sorry you are having so many issues. Wish I lived closer… or work would bring me closer. I would come try to help get you going. Keep at it. It will be worth it in the end.

I am already wired to raw and have ferrite chokes on USB & elsewhere, no coiled cables, controller mounted with thick plastic & rubber pad between it and frame and plugged in with a ground prong free connection, …

What is the “paper trick” you referenced? I scrolled through above and didn’t see it described. Sorry to make you repeat if I missed it.

In case you missed the picture, mine has pretty significant contact to the case. If this countermeasure eliminates my issues, I’ll be asking Langmuir for a refund on scrap metal, $500 I spent expanding my drying system, plus labor hours for investigation and upgrades ![]()

@AVRCUSTOMS the USB contacting the case find is pretty awesome by the way.

I’m hoping it’s the solve primeweld customers are looking for. It’s weird that it doesn’t seem to be affecting other brands of plasma?

Absolutely space that puppy out. Paper trick was just slide a piece of paper between the USB port and case to test. Not a permanent solution!

I had no resistance when the usb was touching. Now with it spaced out, everything powered on I have 10 kohm resistance to the slat bed like it should

I probably shouldn’t read too much into this until I space my USB port off the enclosure, but I have reproduced my “growing” resistance reading twice now. I have 2k ohms when I first turn the machine on, and have seen as much as 30k ohms after several minutes. I asked Langmuir and he said the only answer to that is that I have a defective multimeter.

Since everything else I own seems to also be “defective”, he may be correct.

Do we know this? And if we do, is there something meaningful that could be taken away from it?

According to Langmuir, the electronics enclosure is supposed to provide internal resistance between the USB port and the table frame. Could this somehow be effecting something in the Primeweld voltage divider that wouldn’t be affected by other plasma company’s voltage dividers?

Also, FWIW, it sounds like the Langmuir tech is banking on this USB contact being the cause of my issues. He said that if this does not correct the problem, we need to try a USB isolator next. As those seem the be a couple hundred bucks for decent quality units, I’ll most likely be trying EVERYTHING else first. ![]()

That’s kind of how I feel, Bret. Though the truth is I’ll be so relieved to finally have a usable machine, I’d just take it as the victory it is.

After trying everything else, I can’t even cut a straight line with mine. So here’s hoping.