Looking like an easy fix. I read a repy a couple back from this one. You should have no continuity between the grounding shield on the usb and the table. Not 5 ohms. Ensure that you don’t. This would be a root cause of EMI interference on the table.

You should have 10k ohms between the usb and slat table. I talked to Langmuir about this. My thc WAS NOT working when I had no resistance. Now it’s working, I have 10k ohm resistance.

You can take off the control board and I just used some 1/8” rubber orings behind the board to space it out a touch! Works like a champ

Grounding Considerations

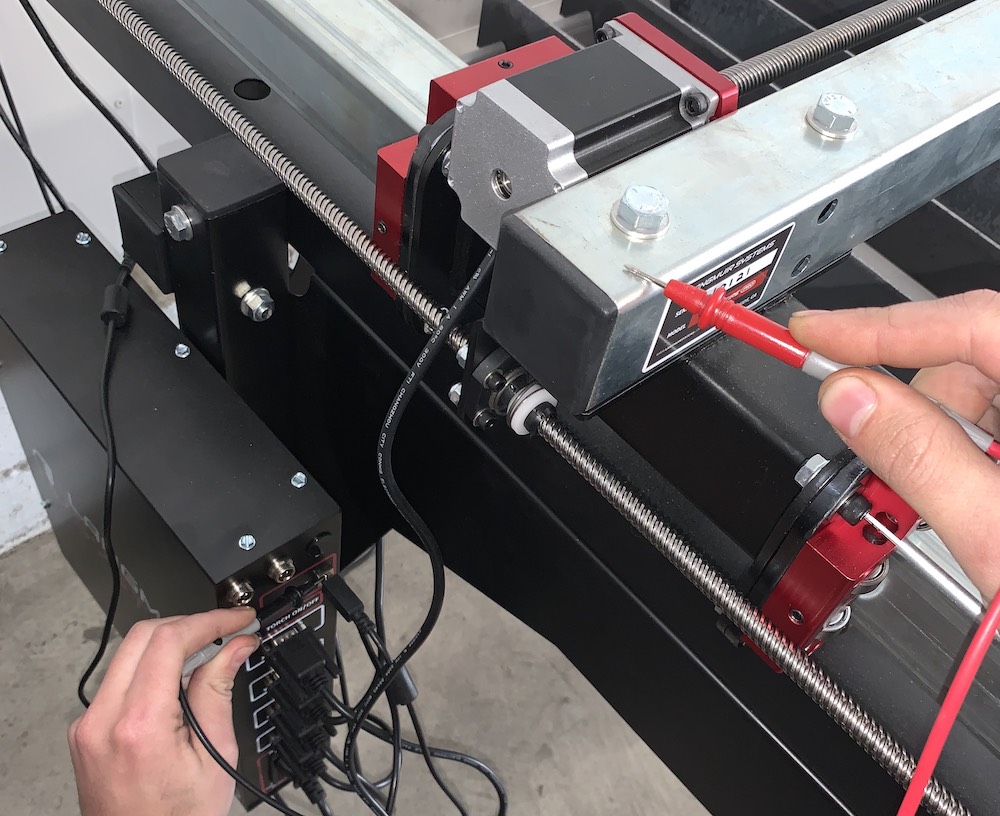

Due to the fact that THC signal voltages can be sensitive, it is important to make sure that USB ground is not connected to the machine frame. This can result in lower than expected voltage readings which can negatively affect performance. Before cutting, we recommend using a multi-meter or continuity tester to check for continuity between the USB plug shell and the gantry tube as shown below. Before performing this test, be sure that:

- Machine Power cord is plugged into the electronics enclosure.

- USB Cable is plugged into the electronics enclosure and your powered-on computer.

- Plasma Cutter is connected to THC VIM and electronics enclosure.

- Work clamp is connected to the machine frame.

- If you are using a laptop stand, make sure your laptop is sitting on it while performing this test. (Its possible the laptop stand fasteners can conduct through your laptop)

If you detect continuity in this test, please message us at Langmuir Systems Support for steps to resolve.

They seem to contradict them selves.

You are correct in saying no continuity to the table, but you do need resistance, two completely different things

Any resistance will show as continuity… I’m glad your working now. I’m also well aware of the difference.

I think the difference is that the test in the instructions does not say to turn the electronics enclosure ON. I read infinite ohms (open circuit) and no continuity with the electronics enclosure OFF and I read resistance with the electronics enclosure ON.

Now, hears the weird part @AVRCUSTOMS and @Bigdaddy2166:

When I first power on the enclosure, I read 2k ohms between USB and table.

I check it again a few minutes later and I read 5k ohms.

I check it again maybe 10 minutes after that and I read 13k ohms.

Why is the resistance in that circuit increasing?

Also, Austin, my Langmuir tech doesn’t seem to know about the ohm test that your Langmuir tech told you to do. ![]()

I guess they don’t work off of a flow chart.

All I can tell you guys is mine has 0 ohm’s. No continuity. I achieved this by using the two prong adapter which eliminates the electical service ground from making a ground loop into the control box. In the two years I have used this table it has not let me down one time. 5 or 10 ohms may be tolerated by the control board in this case.

Good to know, @Bigdaddy2166. Could be another rabbit hole. I’m re-wiring my sub panel today. One of these things is going to work.

Plesae be careful. Double check every connection before you re energize the panel.

Well @DnKFab, connecting the torch and work clamp leads is a big NO NO on a CNC plasma table. Or at least it is with a Primeweld plasma cutter, @TinWhisperer…

After doing this, FireControl froze immediately every single time the torch would fire, and after the first couple of cuts, it started firing the torch but then the arc would immediately go out, which is totally new. Of course, I didn’t get an arc error because FireControl was frozen. Regardless…

At first I figured it must be the Amazon DC extension cables I used to move my plasma further from my electronics enclosure, and I’m not convinced that they aren’t causing problems of their own, but I moved the plasma back closer to the electronics enclosure, and switched back to the original VIM cables, and that made no difference.

So, at that point, I unclipped the zip ties connecting the torch and work clamp leads, and things immediately improved. Then I moved the plasma cutter back over and reconnected my extension cables and I might be back to square 1 again. The Amazon DC cables are thinner than the ones from Langmuir, which concerns me slightly.

I had one successful cut, where FireControl froze momentarily, and then recovered, and then on the next cut FireControl froze in the middle of a downward THC correction again, and crashed the torch into the work really hard for the second time.

Good thing I’ve got a replacement Z-axis sitting in a box…

So, in closing, fixing my electrical service sub panel wiring issues did not solve anything.

And moving the plasma further away, uncoiling the work clamp cable, and routing the VIM wires away from everything else seems to have made no discernible difference to FireControl freezing, and actually seems like it may have made things slightly worse, because I had everything off in the house, today, and only the plasma and lights are running in the shop (air compressor off during tests). That last part is really disheartening. I had the laptop unplugged and in airplane mode too.

Anyway, I wanted to try and be somewhat scientific about the efforts I have made so far; to try and test out the effects of which BEFORE I address the USB port issue.

Tomorrow I will tackle that.

Here’s hoping. Because this is getting really really old.

Also:

Is anybody aware of a very high quality DC extension cable 6’ long or so. I purchased the best one I could find on Amazon, going from reviews, for the purpose of moving my plasma over further away from the Langmuir electronics, but the ones I received are incredibly thin; about half the thickness of the Langmuir cables…

Do you have a two prong adapter in your house? One with no ground connector?

If you can dig one up, plug your langmuir control box in with it.

Or maybe a cheap extension cord with no ground and try to cut something simple.

Check this out! https://a.co/d/6P4L2fq

That’s a good call, John. I will try that first thing tomorrow, before I try the USB repair.

I feel bad for you Casey!!! We’ll get this figured out.

Can you solder? I will send you the copper braid tube to run your work cable through.

You will need to solder a wire term on the end of it to hook up it to your ground rod.

Remember what I said about that Primeweld plasma cutter? CRAIGS List, Ebay, trash can etc.

Email me your address. I will see if I can put an end on it for you before I ship it.

I used this cable to replace my Torch on/off cable, after I stepped on it and broke the connector on the original. It’s 14ga wire and heavier than the original.

10ft 14AWG 12V DC Extension Cable DC 2.1mm x 5.5mm 5521 Power Supply Adapter Flat Extender Cord,Female to Male Wire for CCTV Security Camera,IP Network Camera,DVRs and More Devices https://a.co/d/d3oTOqw

Now we’re talkin’ Dave!! Thank you @ds690.

And I sent you a DM @Bigdaddy2166.

Ok I got your address. I’ll try to get it out tomorrow morning. It will be a couple of days from Chattanooga.

I sure appreciate it John @Bigdaddy2166

That is very surprising to me. It does sound like you are on a good path to get it worked out though. You are narrowing things down. Im sure it feels like banging your head against a wall but keep at it. Your gonna get it going. On a sidenote, does your usb extension cable have ferrite chokes on it?