I have the crossfire pro with the razorweld cut 45 CNC plasma cutter. With the machine torch do you still have to install the torch firing hardware?

You always need the torch on/off cable. It’s what allows the software to turn the torch on and off.

You should have a port on the front of the Razorweld to plug in the torch on/off cable. The other the goes to the “torch on/off” port on the electronics enclosure.

Thank you found that cable and got it plugged in. What about the THC? Do I need the box that Velcro to the side of the plasma cutter, or do I just plug in to the other port on the plasma cutter? There was one little piece of paper that shows it’s a 50:1 divider.

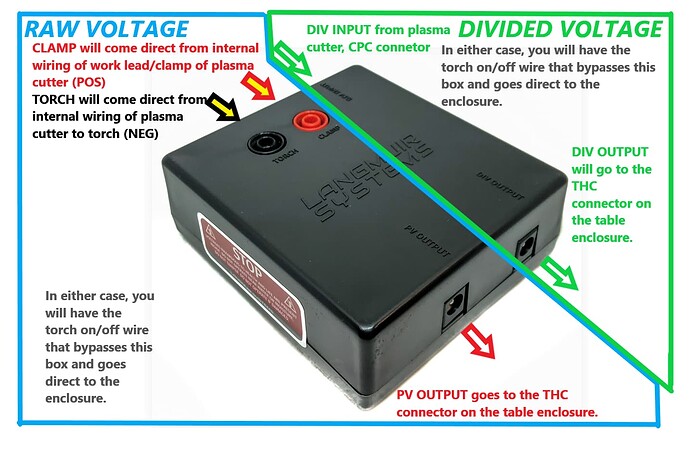

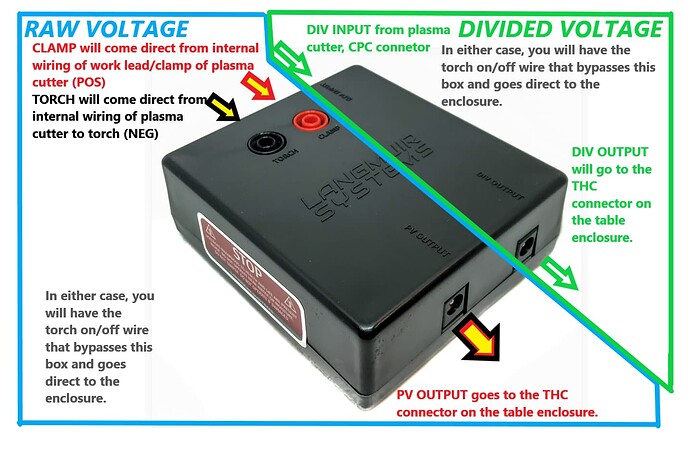

Yes. You need a cable plugged into the divided voltage port that goes to the DIV input on the VIM. Then you need a cable from the DIV output on the VIM to the THC port on the electronics enclosure.

Just be aware that the ports on the Razorweld have been switched several times, so it’s a guessing game for which is divided voltage and which is torch on/off.

Start with whatever the documentation from Razorweld says. If the torch won’t fire, swap the cables and try again. It won’t hurt anything to have them reversed. It just won’t work.

David is always spot on. Another thing that people do is get confused with how the wires are used on the VIM box. Hopefully this helps:

I helped someone yesterday - this is what they had wrong:

All they got was the starting arc but it never switched to the full machine arc.

Fancy Jimmy.

Damit, Jimmy, where did you come up with these fabulous illustrations? I have saved them to my database. ![]()

Maybe Langmuir should start putting a line or marks on the actually VIM box similar to jimmy’s picture. Or painting half the box and different colour on the Raw side or DIV side?

Langmuir should definitely include that illustration in the instructions.

Sadly, it probably still won’t stop people from plugging the torch on/off wire into one of the open ports.

Not hard to follow instructions, but a lot of the people don’t even bother too.

We seemed to have lost our OP in this discussion. No idea if this even pertained to ‘their’ issue.

Hopefully, ‘they’ will report back.

Yes thanks for all the help. It was much needed. Sorry for not replying sooner. Service is spotty dealing with the aftermath of Hurricane Helene.

So sorry for the weather disaster you guys are dealing with.

Thank you for reporting back. As you might guess, all of us try to give our best guess of what will help and it is nice to get confirmation “WHAT” information helped.

I will mark this topic as “SOLVED: wiring corrected”. If that is not correct, please let us know so that someone else finding this topic will know what helped.

Good luck to you and welcome to the forum!

Glad you mentioned this. I am about to fiddle with mine that I have been having an issue with. My razorweld with CNC torch will pierce the plate, but then just cut off. I cant get it to make a cut. I could try to swap them if you think that this might be my issue. I am reading 297v during a THC test which is too high.

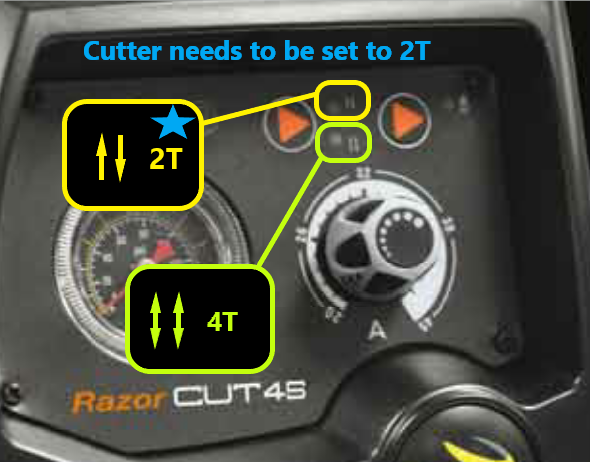

2T 4T button on the front. You must be on 2T at all times. It might look like arrows up and down. It should be lit up on the top

I got that in the right place.

And to follow up on what BigDaddy said: on the RazorCut 45, their labeling leaves a lot to be desired. It only has very tiny graphics and no numbers or letters. This is how it it will appear and what it is trying to say.

If the torch fires at all, your cables are not switched. It wouldn’t do anything(no air, no arc) if the torch on/off cable was in the wrong port

On this thread, the OP was reporting some really odd behavior with his cutter. He said it resolved after he discovered that the air pressure was 125 psi to the back of his cutter. He turned it back down to 75 psi and everything seemed to correct itself.