So today I cut 4 patterns no problem swapped consumables out of the same pack that the last cuts were and I would have an initial arc and then it would stop or it would cut partially and stop. I could get it to cut if I placed a piece of steel in between the torch and the material. I then swapped back to the old consumables and it would cut fine, they were older and the cut quality wasn’t as good which is why I swapped them originally, tried it with a new set, same issue. I also cleaned my ground, cleaned and re tightened the THC cables. Made no difference. It’s a razorweld cut 45. Not sure if I got a bad batch of consumables, they are the razorweld brand and I’ve had good results with them before so not sure if a consumable issue or if I’m overlooking something. It acts as if I have too long of a pierce delay but I’ve ran all these programs before with no issues so I know that’s not the issue, and with the cutting partial and stopping is strange, almost like it’s lifting too high as it cuts. But I also tried it without the THC on and same results so not sure. And I am aware of not having enough slack in the cables causing issues with that, but I tried it on different positions where it would have the issue, as I fixed that issue before. Any input would be helpful.

You gave lots of detail…that is good.

Could you post some photos of how your torch is mounted, and of the consumables that cut and those that don’t cut? And a picture of the front of the machine with it turned on and connected.

Have you measured your cut height? Here is a test gcode that will cycle the torch without firing and then stop at a cut height of 0.06 (plus it might add 0.02 for the springback) so you might measure 0.08.

cut height test.tap (224 Bytes)

And your air pressure is 75 psi to the back of the machine?

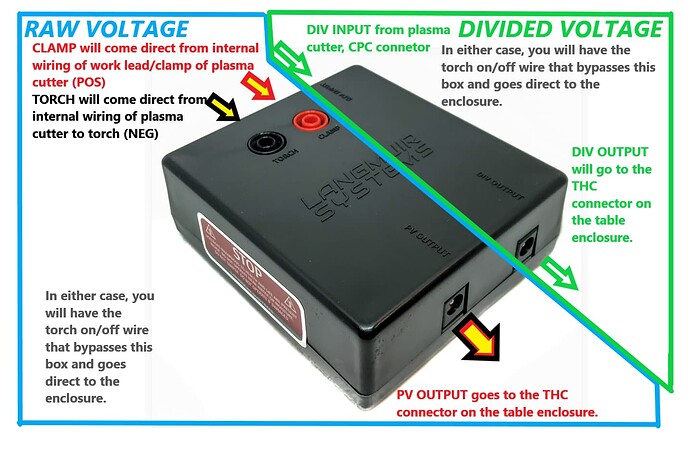

I recently had someone have that exact complaint (torch initially started but then stopped before moving) but he never had any successful cuts. So I am assuming that your VIM box is wired correctly. Are you use RAW or Divided voltage to the VIM?

Are you getting any error on the Plasma cutter or in FireControl? If so, what, exactly does it say?

Everything is working fine now, no idea what happened or what changed but I’ve ran a few with no issues. Maybe a loose connection somewhere idk

I’ve ran it for almost a year now with a few issues I solved, torch is mounted on the upper end where it is shiny, had that issue before and had to get a new torch torch height is set correct at .06 pressure is at 75 vim box is correct as well, it’s been working for a long time with no issues until today. It’s connected div, fire control was throwing the code for THC saying something about pierce delay may be too long etc. it hasn’t thrown the code since it started working again. As for consumables that cut and don’t cut I could send pictures but as of right now they look basically new and are now working so I’m not sure, the older ones have some tarnish to them and have what you would expect from a used consumable with a little recess and some small distortion. I do have an air dryer inline so I don’t believe that to be an issue. I actually just noticed my pressure was turned up sorry some reason usually it is set to 75 so that may be a possibility of an issue there

Old vs issue cut consumables. I have different ones in the torch currently. But like I said in my post before this it may have been my fault having not turned my psi back down was at 120 when I was using the air for other stuff .

Good job. Glad you figured it out.

BTW, comparing those two photos, I think you realize this set of consumables is GONE! ![]()

Thanks for reporting back. I will mark this as SOLVED. You can still post on it. You could even remove the “SOLVED” portion on the title if you want. ![]()