My son uses Solidworks, since he attends a college which has settled on it. He had designed and 3d printed hundreds, if not thousands of parts for robot combat. We have made a small handful of UHMW CNC parts on our MR1. However, I am disappointed in the SW support, specifically their post processor. Admittedly, I am not an expert, but so far we need to basically disassemble the g-code that the prost processor makes into smaller chunks, and run it a little at a time. Am I missing something? Why cant cut control understand canned cycles, such as peck drilling and milling out a larger hole with a smaller endmill? Anybody make a ‘converter’ that can take solidworks, or the full language of g-code, and make it usable on the MR1? Is there a definitive writeup on how to better utilize the post processor? It seems the Langmuir kinda stopped after they wrote CutControl…

I am way out on a limb on this one. I can barely open my hobby license edition of SolidWorks so I don’t know if my response has any merit:

Did you load the “Post Processor and tell Solid Works to use it?”

This file needs to be loaded on the computer that has Solid Works. When you go to the post processing screen, be sure that it links to that file.

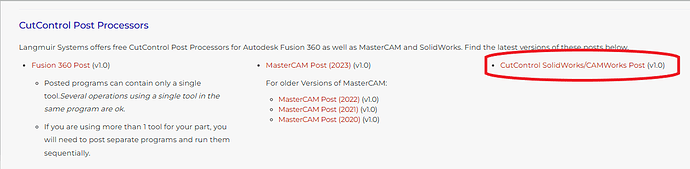

Here is the Download page link:

I’m a solid works user, been so for many many years but I do all my Mr1 code in Fusion. Mainly because I was new to cnc milling and 90% of the guides out there are for Fusion. I have read there are other users on here that use solidworks for processing so I know its possible. It is something I may look back into or switch to another program like solidcam as I want to get into live 4 axis etc.

Regarding splitting the process into chunks. Even with fusion we have to do that, at least by tool anyway. Cut control wont accept the entire file and allow for tool changes.

Many people myself included have or are currently switching out from cut control to another system. I think we can all agree that cut control is a dead project now. The most opted for solution is Linux cnc. I went for the Masso G3 touch but either option requires a control board swap. Just to add that cut control is fine for 95% of users out there, but if you want to add a 4th axis, change motors, canned cycles, change probes or a ATC spindle etc, you have to swap out systems. I am surprised that Langmuir haven’t offered a drop in control panel, Mach 4, Linux cnc, masso g3, UCCNC etc. Let someone else handle the software and updates that go with it… If you retrofitted your stepper drives and the spindle VFD, I don’t see it costing that much.

Had they dropped in the Masso G3 for example (like companies such as onefinity do), it retails for 700$ ish for the board, or around 1300$ with the touch panel. No need to invest in custom software, no need to develop and maintain said custom software. Buying in bulk they would have paid way less. No need to supply Mini PC or touch screen. No need to re-design probes and tool setters. Users could have added an extra axis, swapped out motors, used canned cycles, been able to post the entire process, basically done anything they wanted. All for relatively little cost to the end user.

Yes, we have the post processor loaded, its just not very functional.

Craig1,

Wow, that is very interesting. I did have a guy that built his own X Carve wood CNC that I think uses one of those boards. However, the idea of retrofit is very interesting. I find the CC is very limiting… it works well, and we bought the small PC / touchscreen bundle, but what really interests me is your mention of a 4th axis. That is one item I would really like to have. We need to CNC a cylinder, about 1 1/4" diameter and about 3 or 4 inches long, with features along the cylinder. The 4th axis would make that a no brainer!

I would love to have canned cycles and easy tool changes. If the system could stop and translate over to a reference block where a new tool could be loaded, that would be a step in the right direction.

I am not a Linux guy, and am hesitant to go that way, but what the heck, I can learn! I will look into some of the boards that you mentioned.

Thanks!

This is the route I’m taking. Swapping out servos for clearlink with built in drivers, more power etc. The Masso allows for 5 axis. You will consume 4 of those if you want auto squaring. Leaving one for a 4th axis. Since is uses a more traditional probe set up, I also went with a wireless probe set up to make tool changes easier. Then with the outputs I can select mist or flood and trigger a whole host of other things like solenoids for Automatic tool changes (with a different spindle)

All these things can be done in Linux CNC but require some setting up vs out the box with the masso, hence the additional cost.

This is what led me down the custom path and one of the most in depth write ups on the conversion…

And another post…

Depending on how deep you dive, a few hundred $'s and some long nights will get you there.

I opted to swap my controller out for a Centroid Acorn. It sits somewhere between LinuxCNC and a Masso G3 for cost and ease of setup.

I could have used all the stock components, but opted for more powerful drivers and a few other components that make the machine safer. Also, those of us who have upgraded have stopped using the Langmuir probing tools as far as I am aware. Their design is incompatible with a properly grounded machine. If you use them, you’ll likely to burn something up eventually.

The MR-1 is much more capable now and the post processor is light years ahead of the CC post processor.

I really like how Craig1 put it… Langmuir has evidently totally abandoned Cut Control software. I am somewhat sorry I purchased such a strapped machine… They produced the HW and SW, and just didn’t follow through on either. At the time, how easy would it have been to included the hooks for a 4th axis? How hard would it have been to have a real post processor? I bet if you started writing something in Python or some other popular language, and had ChatGPT help write it, it could be done. Its not rocket science. And to use probes that short out the supply seems crazy, why not make a compatible, swappable touch probe, instead of make something that is poorly designed? I am really frustrated with their HW/SW decisions. They make something that lures us in, then poof, no updates worth mentioning. I think I will abandon their CutControl and do like Craig1 did. Seems like a no brainer!