I’m just wondering has anybody got a fourth access to work on their mr1if so where did you get it from and how did you get it to connect

Rumor is Langmuir has one in the works. We shall see. I am a Fusion guy; the fourth axis is an add-on for Fusion: $1400 per year. As you know, Fusion is only suitable for 3 axis +1 programs.

For my life, google can’t find out what the +1 is or how you would use it. Maybe some of you G code rocket scientists can enlighten us.

I am way out of the league but this is Fusion’s information on the 4th Axis:

Here is how to access it, if you pay the additional $1400 (I assume):

https://www.autodesk.com/support/technical/article/caas/sfdcarticles/sfdcarticles/How-to-create-a-4-axis-rotary-toolpath-in-Fusion.html

And here is a crazy fun video (5th axis???):

Note: I changed the title of the topic from access to axis

There is no way to do a 4th axis with CutControl today. You’d have to convert to a new control system first (which a few of us have done now) or wait to see if Langmuir makes one.

The low Z height limits your 4th axis options. I have a Sherline 4" rotary table that just barely fits, but does work. I haven’t finished wiring it up yet, so I don’t have any demo videos. I’m in the process of rewiring my machine with Clearpath servos, and when that is done I’ll also have the 4th axis.

3+1 is just a very simple 4th axis that only positions the part, it’s not used in sync with the other 3 axes during machining for complex geometry.

I talked to Jake about the fourth access and he told me there is something in the woods but we just have to wait apparently it will be simultaneous for faxes we’ll have to wait and see otherwise I will do a poor man’s fourth

Ok guys I did some research on how much it cost to do the item for fusion 360 now the $1,400 is for the full manufacturing suite you can select which parts you need and the price is much lower each one of these add-ons brings up your bill now in doing some more research I found a thing called a poor man’s fourth so I will be doing some more digging into this and to find out whether we can use this or not if I get the info and the drawings for this maybe this might be a short-term solution until Longmire come up with their own

what I really want them to have in the works is a 10k ATC iso20 spindle! That would be and epic game changer! That would be more useful to me than a 4th axis. ![]()

Agreed, but it should really be at least 15k rpm if not more.

why would you need 10k ??? this unit only has a small motor with good cutting speed a 8k .I do most of my cutting at 6500 rpm with the right feeds and speeds on steel and 7500 rpm on ali with a 2 flute 5/16 or 3/8 .this is not one off the big boys toys that cost three time’s what we payed for the MR1

I switched my MR1 to a 15k spindle a year ago and use 12-15k speeds all the time in aluminum. For example FSWizard with conservative settings recommends running a 0.25 carbide endmill in 6061 at 15k at 50ipm and will use 0.5hp spindle power. This is well in the capabilities of the machine.

If you do it at a maximum 8000rpm the feed rate drops to 21rpm.

There is a trade off — my machine has much less torque under 1500rpm, which hurts my ability to use large HSS drills. This isn’t an issue for my jobs since I interpolate large holes.

A 25k spindle might be even better for milling but would have so little low end torque that HSS drills would be really limited.

I run mostly aluminum so 15k spindle would be very nice. When I run 4mm 2 FL endmills it have to go so freaking slow. Also when I engrave… hhhhhhhh… I still run steel parts some times so I don’t want to give up all my low speed torque. I almost never drill, and this thing can’t rigid tap so I don’t really need the torque at 1000 rpms. I want to be able to run as low as 4500 rpm for larger cutters on steel. In that case I don’t know if 15k max would be too high or not??? That’s why I was thinking 10k or 12k

I have pretty good torque from 2500 rpms up to 15k rpms with the CNCDepot FM30F. Steel isn’t an issue, I machine steel and stainless fairly often, usually with 1/4" 4fl endmills.

Are you running Cut Control or did you switch to Centroid, Linuxcnc, or Mach?

yes i am still running cut control but i am thinking of doing a new set up that will let me have 30" in the X and keep the Y as it is using all the MR1 parts

I run LinuxCNC. I moved away from CutControl quickly after building the machine.

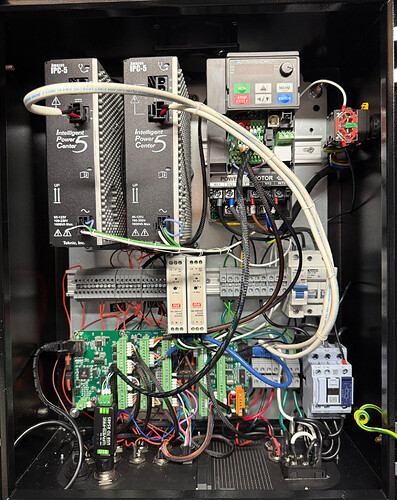

I actually just finished making a new control box and now my electronics don’t have anything in common with Labgmuirs. Besides changing the spindle I also changed my steppers to Teknic Clearpath Servos. I changed my electronics enclosure to one with a door that is mounted on the wall next to the machine. I redid the AC inlets to be safer and cleaner.

The top has two Clearpath power supplies and the spindle VFD. The middle is all just power distribution, and small power supplies for electronics. The bottom has a Mesa 7i96s for LinuxCNC integration and a Mesa 7i84 for I/O expansion as well as a contactor to control power to everything.

Also for this thread I did wire up the A axis, but haven’t configured it yet. I need to make a homing switch too. I have a project for it so that may happen soon.

that looks like a lot of work .where do you find all the info to do some thing like this ?? .What made you do this ??? and what more do you have to do to make this work .

It’s a lot of work, but work that I knew I’d be doing when I bought this machine. All of the other machines that I considered didn’t have electronics (sold as CNC ready) and I’ve been doing this anyway.

The MR-1 is a hobby for me, so spending time making it better is worth it.

The stock spindle and software caused me to make careless mistakes that slowed me down and broke parts and endmills. I always knew that I’d want a spindle with a drawbar and software with proper tool changing routines.

The switch to Clearpath servos was much less necessary, but I took the leap when I saw a machine’s worth of servos and power supplies for a good deal on eBay.

this is going to take some time to get of the ground with the lack of time i have BUT i will post how this thing is coming along soon .

I think it is going to be around 2000lbs-2200lbs with all that i have plan to use on this project

Nice! I have a Centroid Acorn board I’m going to use on a CNC lathe project. I purchased it before I heard of LinuxCNC.