FIRST EVENT OF THE YEAR…

We were invited to be a vendor at the Jet Boat Race Pits for a 3 day event this year! They’ve never had craft vendors there before and 1 other showed up for 1 day.

The first night was 3 hours at a Show and Shine on 3 blocks of main street. It was pretty busy. Saturday and Sunday were 9-4 at the Pits. The traffic surged as the racers prepared and left the start, then subsided for an hour or so, then would pick back up as the boats returned. 4 surges per day total…

We had a great time, and cleared $1500 in sales. I am so glad we had the ability to accept debit and credit cards. Minus expenses and material costs, it’s about $1100 net profit. Not bad for 17 hours of selling time.

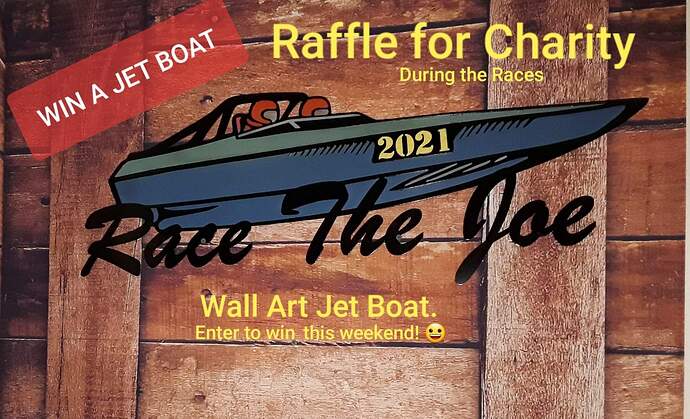

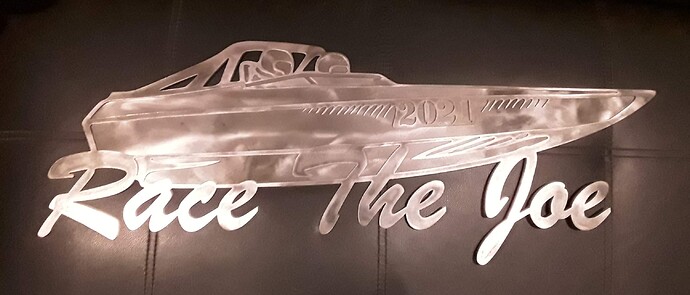

We also held another raffle for charity, with a 34 inch 2 layer jet boat going to the winner.

Here’s a few pics…

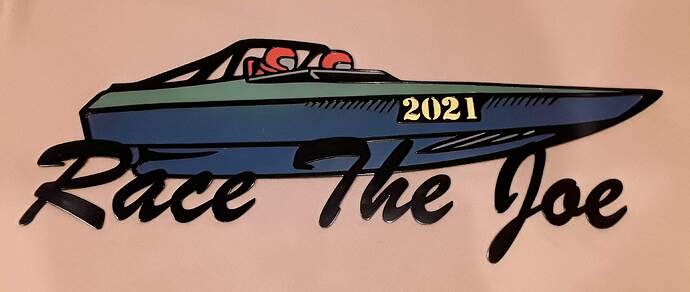

The inspiration for this large piece was the smaller one below. It was really fun to design and create this 16 inch, 14g, sprayed in 6 different metalcast colors.

Not knowing how these would sell, I only made 8. Big mistake. We sold out in the first hour of the Show and Shine on Friday…damn… I got home and fired up my Pro at 11pm and let her fly on 18 more. (my THC had been acting up the other day and I was worried:grimacing:, but when I fired it up everything ran flawless… wierd…

) Stayed up all night and cleaned, sanded, primered, and sprayed all 18 in metalcast paint, and had them dry by 7am, right before we left to get set up and open by 9am on Saturday.

Was tired as hell, but sold 12 more for another $240! Turned out to be my best seller. Acounted for almost a 1/3 of the total sales. Think I started something here. Now I need to come up with another limited edition commemorative piece for next year. Have also decided to follow the races for a bit next year, with an emphasis on nautical themed garb.

PS. Saltwater ball bearing spinners and some bailing wire are great for hanging your art around your canopies. The will rotate in a light breeze, drawing attention to your stuff.

We have already received 3 ($100-$200) custom orders during and since the show. One of these I designed on my laptop at the show during the lulls in the traffic and is ready to cut.

Hope this gets other owners excited about getting out there and pushing your work…

!

!