That’s the one you should rely on. The other one was created back when Razorweld didn’t have a chart of their own. We had to test to figure out the settings that worked and posted our experiences on it. Hypertherm always had a good chart but RW didn’t so we made do the best we could ![]()

Where do I find this spreadsheet you’re talking about? I’m teaching high school kids how to run this and really don’t want to have to test it all for myself.

Thank you

Search for Cut Chart and you’ll find a link.

Where can I find this spread sheet that has been referenced in this conversation string?

By

There is numerous post from myself and many others off test cuts on different material thicknesses on this forum.![]()

![]()

![]()

![]()

![]()

Starting points only as you’d have to dial it in with your particular cutter/torch:point_left:![]()

This comment wasn’t clear enough?

Also you would need to know what torch was on your Razorweld 45 to know what chart to use.

![]() correct! I’ve only upgraded to the PTM60

correct! I’ve only upgraded to the PTM60

You built for me awhile back.

And all my documented results from my test cuts with the RAZORWELD hand torch OG.

have held up on the PTM60 Torch with only a few tweaks of some settings on different Gauges of sheet.

bumping up the air pressure 10 psi from 70-80

A minor ipm adjustments to reduce dross.

It was very easy to run a few quick test cuts with the reference settings to dial in the torch.

The torch has been flawless so far

.060” 30” monogram any dross just flaked off with a finger nail

Thanks for the info.

.105”. HR Sheet

35A

80 psi CLEAN DRY AIR

72 ipm feed rate

79 ipm lead in and lead out

1.0 Sec. PD

.9 tip

PTM60 machine torch

.9 tip always coated with Anti/spatter!

Water table & water height .750” - 1.0” from material . Always!

No bevel and 99.85698% dross free!!

Ya know, I never really thought of this as a factor in cut quality. Thanks for pointing it out!!

I second the anti-spatter.

For the water level I tend to stick to 3/4" although I’ll go to a half inch for 18-22ga so the water can keep the material cool and I get less warping.

I’ll need to adjust my autofill switch. Hmmmm, maybe a programmable one… yeah, a new project!

I love people who brag with photos of their great cuts and back it up with the settings…

we appreciate this…it shows that perfection can be reached…gives us hope…makes us…

Oh Hell…what am I saying…I am jealous as hell…hehehehehehehe

Toolboy: bragging…

Yea I guess so! Lol… but hoping the settings give someone else a starting point to get a decent cut and go from there…

These setting were about the same that I used on the hand torch that came with the CUT45.

I’ve had great cutting results from the PTM60 and the CUT45 OG machine so until the OG RAZORWELD CUT45 Takes a crap on me Ill keep cutting my customer pieces with it.

I have the X45 Machine Torch as well . It’s supposedly uses a lot of the hypertherm parts and consumables and reviews from users are stellar.

But haven’t dove into that one yet.

Here’s a link to that cut and the PTM60 in action!

https://www.instagram.com/tv/CMVaCu7DjNx/?igshid=72vzm2cgbc3j

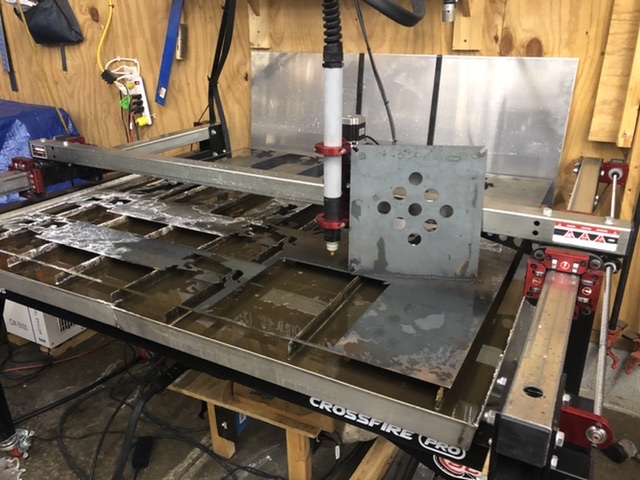

HJust cut this Drain cover I drew up in FUSION360.

For our barn we ride at… it approximately 10x10”

With 1.0 drain holes

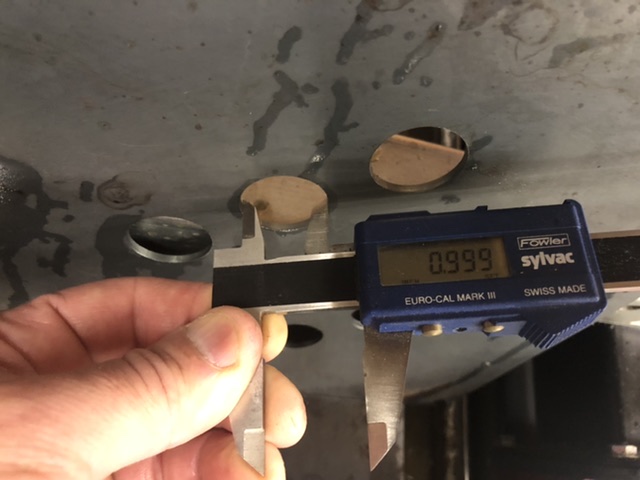

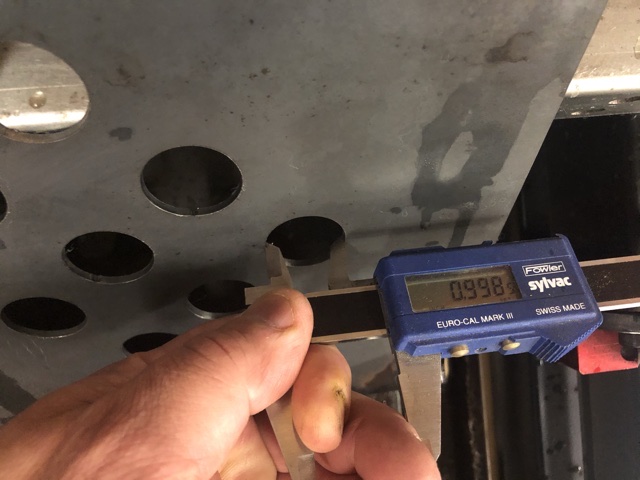

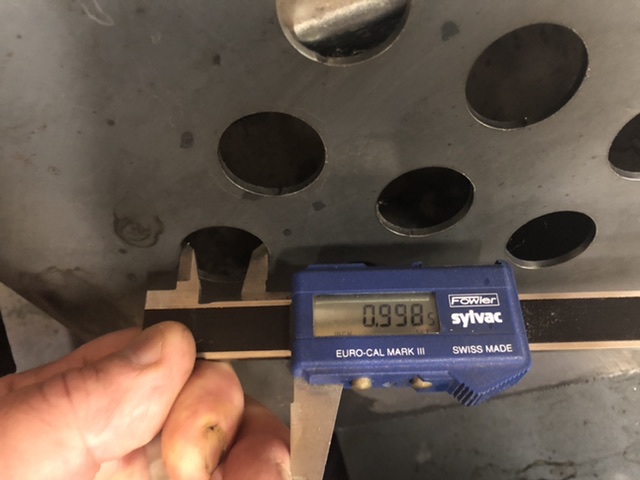

I drew the hole up to exactly .998 in the sketch to see how close the Pro would get to actually dimensional spec…

Also ran the holes 30% lower feed rate from the 72ipm , SLOW DOWN ON THEMS HOLES!![]()

OG CUT45 From RAZORWELD

… wait for it…

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

PTM60 torch

80 psi

.7 PD

.9 nozzle

No lead out

60 deg lead in

.080 Pierce clearance

73ipm

78 ipm lead in

No dross

No bevel

Anti spatter

.800 “ water to material distance

it is so nice when all the stars align and the heavens open up to reveal a glorious cut…well done…

Noticed the Cut Chart was getting a little gummed up, i.e. blank pages, alpha characters in numeric cells, etc. Took it upon myself to give it a tune-up. Not trying to hijack anybody’s work here. Just did a little tappy, tap, tapping for my own reference and thought I’d repost if others want to take a gander. I am not the Chart Master…

Thanks for doing that. These things are community property so it’s good when someone steps in and fixes things up

It was originally only supposed to be a short-term thing while RW & Langmuir developed their own cut chart but that never happened.