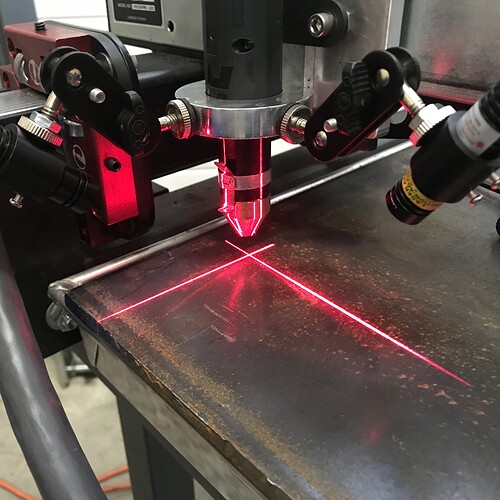

I wanted an easy way to tell If I will have enough room when nesting jobs on scrap material so I added laser sights to my table. I’m still working on cleaning up the wires and finishing the install but these things are going to be sweet!

I saw your other post with a picture of these.

Where did you get the lasers? Are they a commercial sighting system?

I’m not sure why the photo posted on my other post as well. ???

Anyway, no it’s not a commercial system. The mount was made by @Lil_Abners_Kustoms and I bought both lasers w/ mounts on eBay for about $30.

I’ll post a link a little later this evening.

Thanks. I’ve ordered a couple for my unit.

I honestly would like to have that for my machine. A lot of times I’ll cut out a small part in a skeleton sheet and its always a bit tricky making sure that that the cutter wont go over the edges.

I’m going to modify the stock torch mount to attach these to. I’m going with the twin lasers but they have a version that is a dot and they have a cross-hair version as well. Based on my experience the dot is less reliable from an aiming perspective. I thought about the single laser cross-hair but the double laser seems like it will potentially be easier to adjust to get the intersection spot on and the lines can show the edges.

All of the large commercial tables with laser alignment that I could find online all used two line lasers vs a single cross hair or dot. I think easy alignment is the primary reason for this… I decided to just go with a system that mirrored the larger machines.

Yeah I liked that approach. The singles are a pain to keep tweaked because of the movement of the head on lasers - fast accelerations and corresponding decelerations tend to shake things off alignment. And I’m not gonna argue with the success someone else has already proven

Seems like the line lasers enable the cross hair to be aligned to the torch no matter what height the torch is set to.

I agree. I think a the center of a single cross hair (or dot) would move depending on torch height.

What output power did you get

The lowest - 10mw. Anything more is overkill. As it is I wish they were half as bright as they are.

O!! I like this! I’ve been thinking about this and I was thinking about projects where the material is bigger than the table so when you move the sheet you can square everything up again!!

Definetely would make indexing easier.

Put this setup on some sort of spring clamp or set screw clamp and just use it for alignment, then pop it off quick to run the machine. Would allow you can keep the weight off the carriage/gantry, less weight jerking around on everything when running higher feedrates and keep them away from the splashing doo-doo water.

Haha, Doo-doo water.

I thought about the added weight being an issue, but it’s minimal and so far doesn’t seem to matter. I also put clear bra (the clear rock chip stuff that goes on the front cars to protect paint) over the lenses to help protect them from the poo-water and sparks.

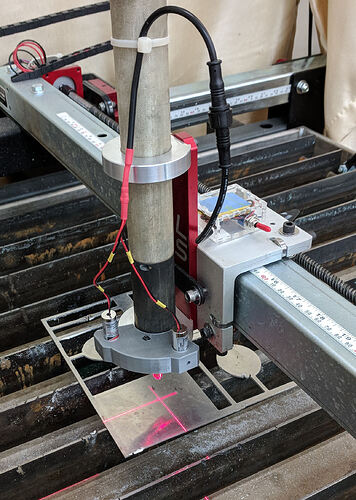

Not quite as sophisticated as OP’s, but they get the job done! Holder is 3D printed and attached to Steve Abner’s Machine Torch mounts. Battery operated from LiPo battery pack mounted on the carriage. There is a USB connector on the pack for recharging.

I’ll post the BOM and alignment process in a few days.

Very slick Tom! I like the easy toggle switch an all.