welcome to the forum Lance…

Well i finally got my table set up. Want to give everyone on this forum a shout out!. Im a computer moron, and there is no way i could i figured this stuff out without all the wonderful information i read on this forum prior to my table arriving. From the person (whom is way smarter then I) giving the download of the dimple die, to the the individual who posted a video of how exactly to wire up my specific plamsa cutter. Thank you!

I ended up buying a 3d printer, printed out 2 dimple dies, figuring if it got buggered up on the first drain i wouldnt have to wait. Needless to say i have 2 perfect dimple dies, sets of backing washers, botls. I would like to offer these up to anyone who needs them, i am more then happy to print more. I will even pay for the shipping. Just my way of paying forward the help ive already gotten from this community.

I have had my table assembled since October and I have barely used it, I think I have cut about a dozen pieces since I have had it and those were all within the first month. I haven’t used it since I have been wanting to modify things and get it dialed in. I definitely want to build a base similar to what is shown on this thread. I originally had it setup with a smaller plasma cutter with a hand torch and I found a great deal on thermal dynamics cutmaster a120 with the machine torch. Since day one I have wanted a permanent computer and touch screen monitor. I wanted a commerical / Industrial touch screen monitor and about a week ago I found a deal on a couple brand new elo 22" touch screen monitors and when I arrived to buy them they were not just monitors they were actually integrated touch screen displays with I5 8500t processors and 16gb of ram. As of tonight I have a computer permanently installed on my pro.

My next mods are to build a platform for the table to sit on, I prefer that method since I hate drilling hole or welding on things, I am ocd about that so everything I do has to be clean and bolt on so I can always change my mind and put it back to original. My other goal is to install drag chains and I am debating if I want the torch lead to be installed in the drag chain, I do have a 35’ machine torch. I am on a mission now to get it dialed in and to start using it for what I purchased it for.

Nice job. Can you share the dimple die file for the 3D printer. Thanks

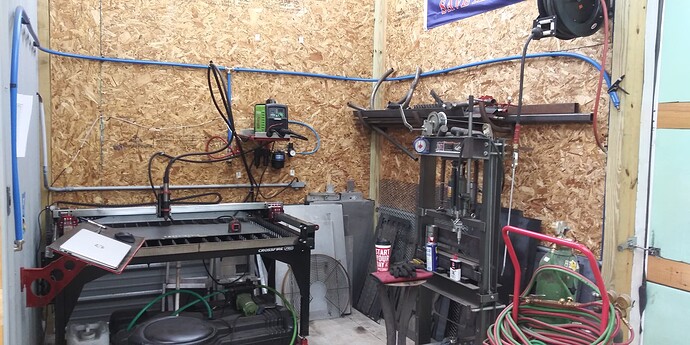

I built a table for mine to sit on. Let me know if you have any questions. These pics were taken just after I finished it.

These are direct thread ins to the leveling feet inserts, Langmuir strongly recommends against using them but if you’re just rolling around on a garage floor they should be fine. If you’re looking for casters to use on a rough surface you might have to buy different leg inserts before installing casters. The leg inserts on these tables are really intended for a stationary vertical load. There are inserts that will better spread the load laterally for moving around, you can find them at McMaster-Carr.

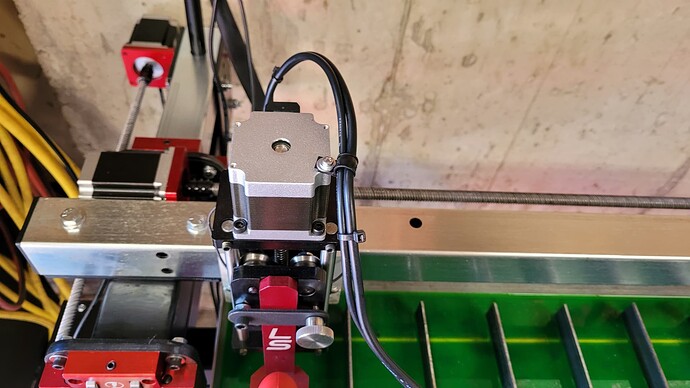

It’s not much of a mod but in the area of cable management I added a curved cable holder to the top of the cable hanger to reduce the load and curve of the bend for the plasma torch line and the Z axis cables. It’s a washing machine drain tube that hooks into a wall drain, I just painted it black and bolted it to the end of the cable hanger.

I also added a P-clamp to the top of the Z-axis motor to hold the wires coming out of the Z-axis because they were hanging up or riding up and down the Z-axis when the carriage ran from side to side. There is about 6mm of threaded open holes at the top of the stepper motor but they are small metric thread pitches, I believe 4mm.

Like nearly everyone else I also built a shelf for the plasma cutter to sit on and put casters on the legs.

Eventually I will probably setup a water tank system although I’m inclined to leave the table full. The only reason I can think to drain the table is for cleanup or moving the table.

Her is mods I did on my pro, been using for three years trouble free. The new XR I will do a roller base the same to it.

Well, it’s been two years since I built that table dolly. So the designing has been long done.

I attempted the same casters you have posted back about 4 years ago on my first crossfire. They failed just sitting in one spot, I learned the hard way and probably a contributing factor to why Langmuir doesn’t recommend them. I ended up tack welding the plates to the tube which kept the caster in place. So, this time around the Pro I went with a different set-up. Good luck with your project!

@Kj6bab I like your computer setup. Would you have a link to the articulating monitor arm and possibly what computer you have. I know its been 7 months since you posted it so I’m sure the exact deal you got is gone. But I am interested in stand alone touch screen computer. I’d like a dedicated setup instead of sharing my everyday laptop.

The mount that I am using is a Huanuo brand mount that I purchased from amazon and it was like $45. I decided on the pole style mount because it was the easiest style of mount to modify so I could cleanly attach it to the table without drilling holes or having a funky desk mount base. I was recently at my transmission parts supply and I saw the mounts they use for their monitors and they are ergotron lx series mounts and they are polished aluminum with gas struts. I am keeping my eye out for a cheap one on ebay since they retail for around $300.

The computer is a ELO ESY22I5. ELO makes really good commercial / industrial displays and I was originally looking on offerup for a good deal on a ELO 22" touch screen monitor and I was going to use it with a Lenovo Thinkcentre tiny computer

During my search I came across a seller selling 2 ELO monitors and the seller did know what model they were so I went to look at them and that is when I discovered they were integrated computers. I bought them both for $150. The only downside to them is the intel integrated graphics but they do have better specs then the computers that come with the xr tables. They actually have some pretty cool features like a integrated analog I/O board in them that can be used to control devices. They also have edge connect which is expansion ports located around the edges of the computer. one of the devices is a color changing status light that I am trying to figure out how to integrate that with fire control. They also sell handles that can be attached to the expansion ports which I purchased so I can easily move the screen without getting it dirty. I really want to use the built in analog I/O board to control a few things on the plasma table possibly to drain and fill the table from the storage tank and I was also thinking about installing a relay in the tables electronics enclosure so the computer could kill the power to the stepper motors automatically if the program crashed or became unresponsive. I just haven’t had any free time to play around with it.

https://www.amazon.com/HUANUO-Single-Monitor-Stand-Adjustable/dp/B08FB7WFCT

I have a triple monitor stand made by Huanuo and it’s been fantastic. I’ll definitely be buying from them again

Brandon, Thanks for the info. Looks like you got a great deal on the ELO computers. That would be pretty cool to have additional control function directly from the touch screen.

I did a quick search for this type of touch screen / computer. Seems like I have a lot to learn about computer specs.

I’m an old school fabricator learning cad/cam and its been interesting. I embrace learning new stuff. But I like to use the filter “Is the juice worth the squeeze?”. Understanding what computer specs I need for a particular application feels like a lot of squeezing with very little juice for the effort. Since I don’t often have need to source computers. Would you be interested in selling me one of the two units he bought? No pressure. Figure can’t hurt asking.

All that being said, I’m hoping that someone could give me a crash course for good, better and best on a stand alone dedicated touch screen computer to use for my crossfire pro. I’d like to be as frugal as possible as this will only serve the one function. Any help is appreciated.

Would you happen to have a link and or photos to it. I’d like to take a look.

https://www.amazon.ca/Triple-Monitor-Stand-Articulating-Aluminum/dp/B084RF63FK

My cable management is lacking but I do love the stand.

Wow! That’s impressive. Is that a rest for your forearm I see? Is it for wrist anti-fatigue?

Thank you, this setup work great for me.

yes. it really helps my shoulder and arm during long CAD sessions.

https://www.amazon.ca/Aluminium-Ergonomic-Computer-Horizontal-Direction/dp/B076H7Y8KG

@Hellbent regarding the drain, is that a nipple into the existing drain into 3/4" PEX?

Yes sir it is, and it still works great. I use it to fill and to drain the table.

@Hellbent what GPH pump do you use to fill the table?